RFID 仿真/模拟/监控/拦截/检测/嗅探器

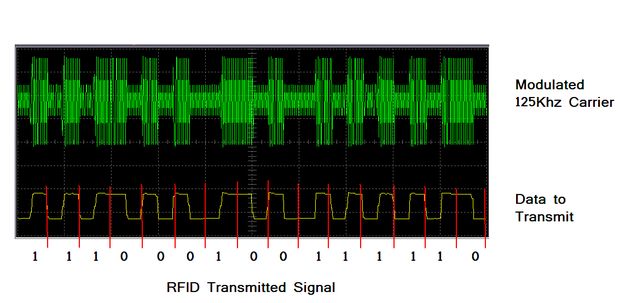

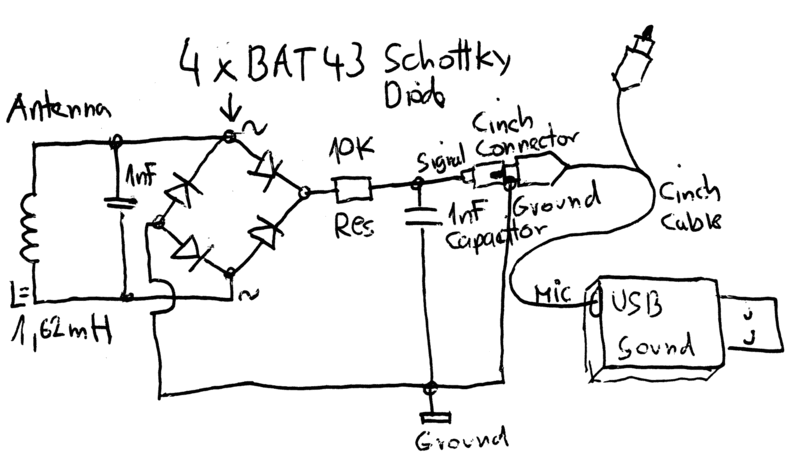

Sound card based RFID sniffer/emulator

(Too tired after recon.cx to do draw the schematics better than that :) Stay tuned for the next version including Tag emulation.)

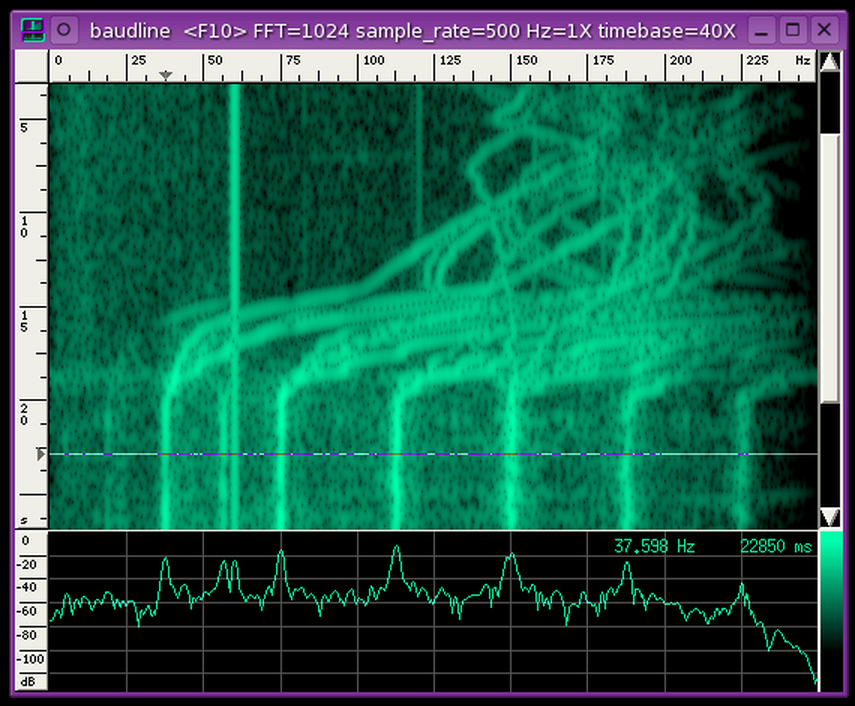

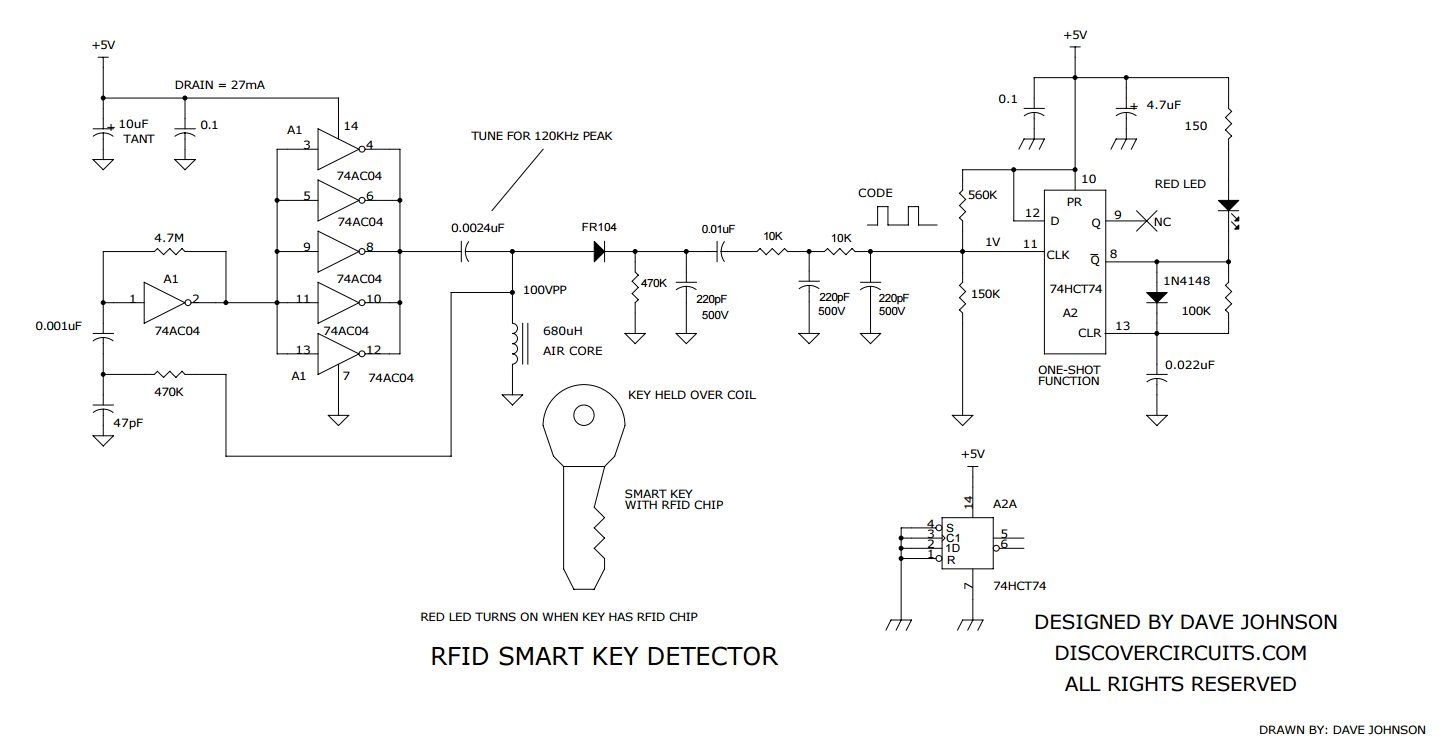

- baudline FFT signal analyzer for sniffing LF RFID tags using our sound card based RFID sniffer/emulator (more information soon!).

PicNic - yet another emulator/spyware for HF RFID

Abstract

Rather than a final construction, this is just an experimental kit addressed to anybody, who wants to play with e.g. MIFARE chip emulation etc. It has two main parts – HW module which is a simple microcontroller driven HF RFID transceiver and a particular SW module which does the particular job (fake UID sending, terminal spying, MIFARE hacking, etc.). The modules currently available in public are listed bellow. Of course, it is definitely up to you to build your own HW/SW modules basing on some of those already existing. Remember – this is a kit... it all started as a demo project for my students, then I decided to put it here - just for an inspiration.

The name PicNic itself explain the main design paradigm and also tells why I did construct „yet another emulator/spyware“. The word “Pic” comes from the name of the microcontroller family being used, while “Nic” comes from the Czech word for “Nothing”. So, PicNic = PIC and „Nothing else around it“. Thus, in opposite to the other designs available on the internet which often try to be as robust as possible, I searched for a minimal design possible. I do not say I have reached the absolute minimum, but I feel I am close enough.

The whole design is addressed to people with a moderate knowledge of radio electronics, PIC programming, and RFID technology.

Documentation

Rosa, T.: PicNic for HF RFID, Santa’s Crypto Get-together 2008, Rump Session presentation, Prague

Klima, V. and Rosa, T.: PicNic pro RFID-KV, Sdelovaci technika, 1/2009

(this article is in Czech, I hope I will find a time to translate it; nevertheless, the scheme and short notes presented bellow together with source code comments in assembler files should be enough to understand how it works and how to build it up)

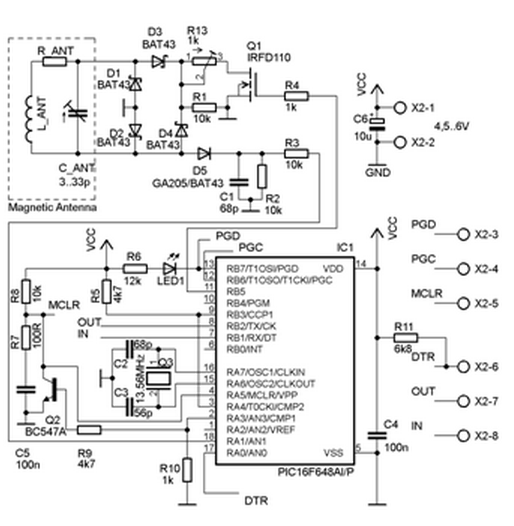

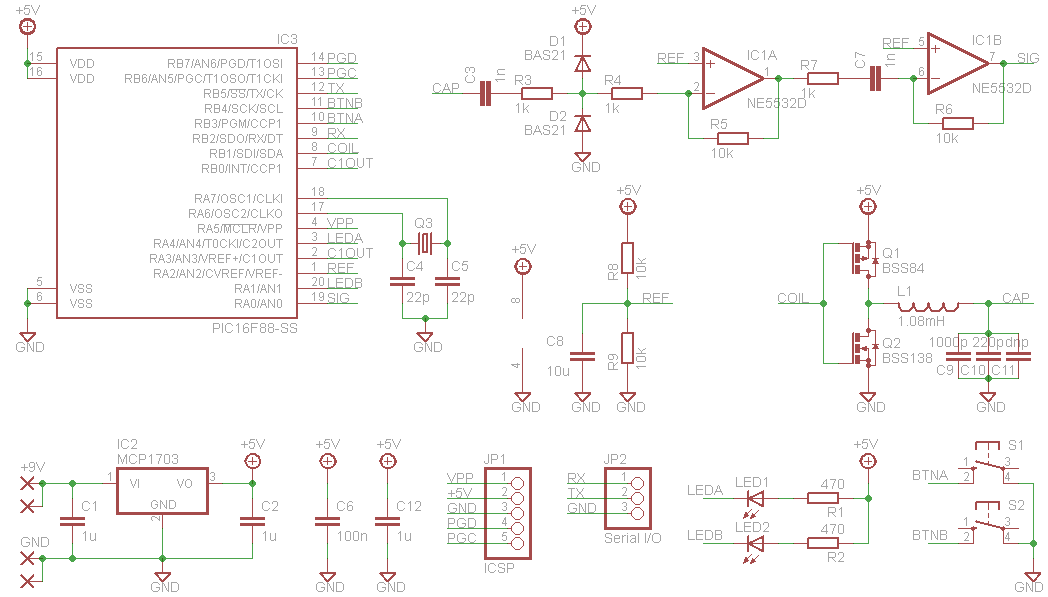

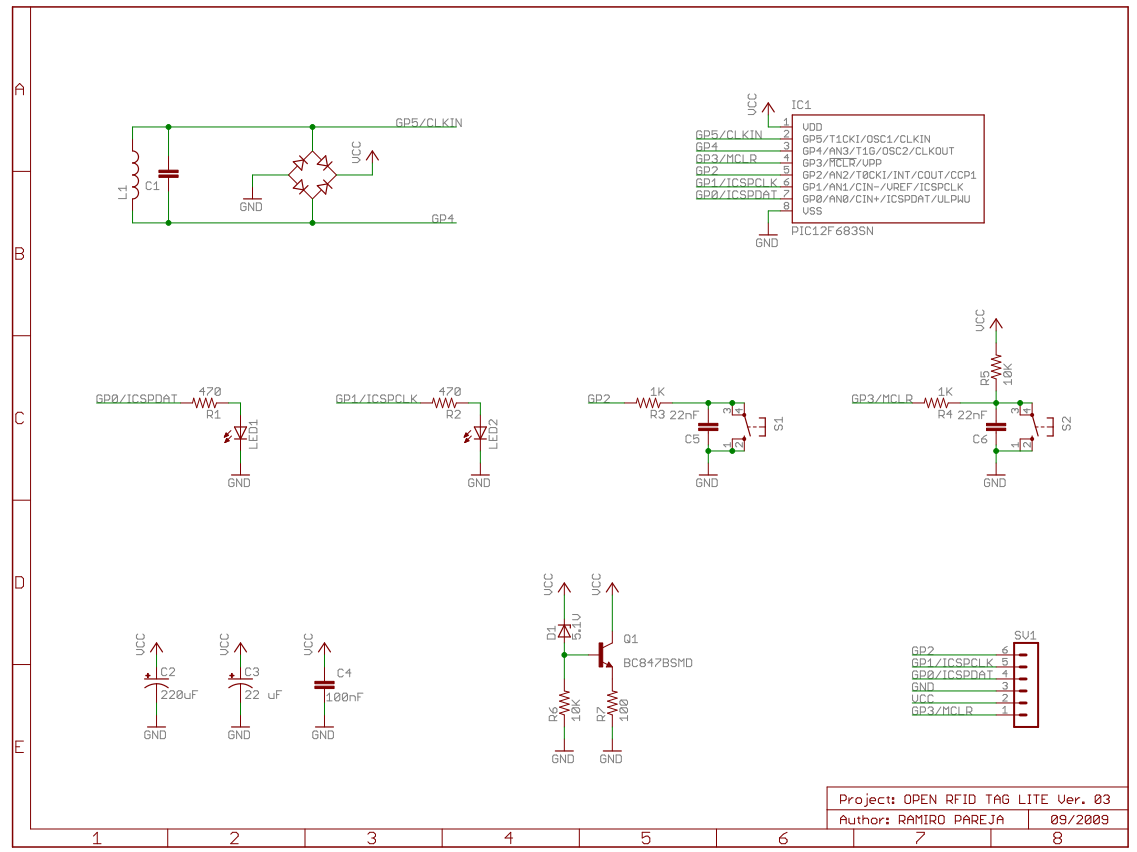

HW design

Note on the PIC clock source

The microcontroller oscillator is driven by X-tal with parallel resonant frequency at 13.56 MHz. We should use a parallel cut with a load capacitance approx. 30 pF. Using the same frequency as of the basic carrier, we can get easily synchronized with the RFID terminal on the very basic level of the instruction flow.

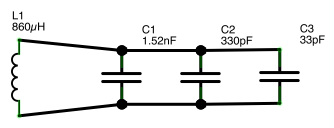

Note on the magnetic antenna design

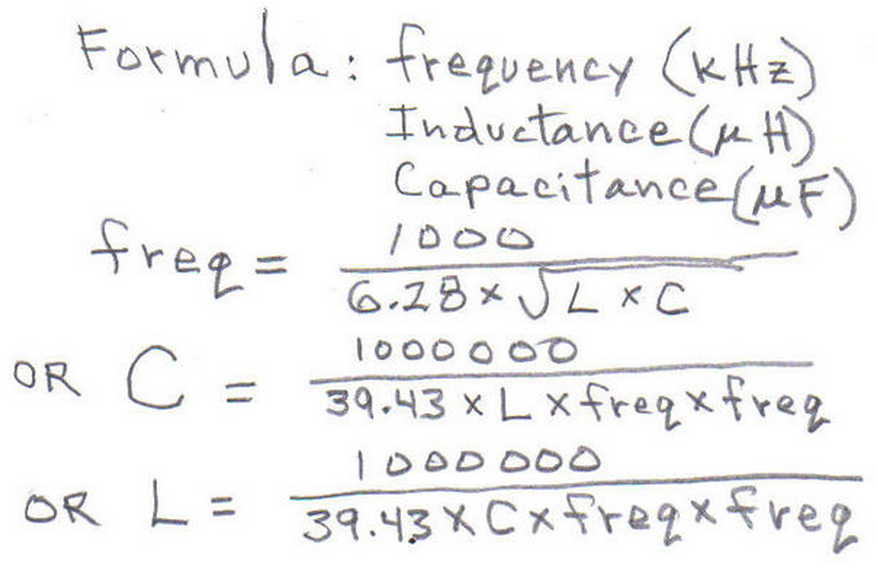

The analog part uses magnetic antenna which is dictated by the fact that HF RFID operates in the near field range where the inductive coupling is reasonable. Rather than a particular antenna type, a general design rules are presented here. The antenna is composed of the main coil, the serial resistor, and the resonant capacitor. From the electromagnetic field viewpoint, the coil should be constructed as 4 to 15 turns in a plane around a surface similar to a general ISO card. From the circuit viewpoint, the inductance should be kept at moderate level (tents of uH at maximum) as we need to set the resonant capacitor accordingly. The well known Thomson formula can be used as an estimate here:

f = 1/[2*Pi*sqrt(LC)].

Furthermore, we must care about the quality (the Q factor) of the antenna as it limits the transceiver bandwidth. Let us say we need 1.7 MHz bandwidth (as the subcarrier for ISO 14443A is 847.5 kHz), then we can use the following estimation for the serial resistance:

R > 3.4*Pi*10^6*L.

We keep the value of R_ANT as low as possible otherwise, as we do not want to mute the antenna too much.

A classical diode AM detector is coupled to the antenna directly.

Its output is then fed to the analog input RA1.

An internal comparator is working there which output is fed to TMR0 and CCP modules of PIC.

TMR0 is used to “de-modify” the modified Miller encoding used by ISO 14443A for terminal data transmission.

The CCP module is used as a capture register for TMR1 which is then used to synchronize the time frame for the emulator response

(cf. ISO 14443-3A for the detailed requirements).

Another part attached to the antenna circuit is the load modulator.

It is composed of a Graetz bridge which load impedance is driven by an induced N-channel MOSFET.

Note that using this technology over a classical bipolar transistor turned out to be necessary

due to a poor switching characteristic of the bipolar one when driven by an asymmetric input source at 847.5 kHz.

On the other hand, the gate saturation voltage affects the minimum power requirements of the whole PicNic.

If we want to go bellow 4.5 V, a different part with a lower saturation voltage should be considered.

The whole modulation impedance is mainly resistive and the resistance can be adjusted by R13 (we start at the value of 100 Ohms typically).

The MOSFET itself is driven by RB5 digital output.

Note on the external communication

The design expects an USART connection to the outside world as well. We shall not forget to do a proper signal conversion, of course.

To connect a RS232 of PC, we can use, for instance, a well known MAX232 convertor of Maxim.

We can also use the FTDI chips if we want a straight forward connection via USB.

I also have a very good experience with the Bluetooth serial adaptor OEMSPA311i of ConnectBlue.

The particular communication speed etc. is up to the particular SW module.

As the clock frequency is the same as of the basic carrier,

we can derive the (13.56*10^6/128) bps (approx. 106 kbps) or (13.56*10^6/64) bps (approx. 212 kbps) easily.

The question is, of course, what we can set on the receiver’s part.

It is worth noting that FTDI controllers are equipped with so-called rational (or sub-integer) divider

which allows quite precise setup for wide range of communication speeds. This is another reason why using the FTDI chips is quite reasonable.

The signals used for the communication are Rx, Tx, and DTR.

There is a circuit (cf. the scheme and the source code initialization) that performs automatic hard reset of the PIC on each DTR signal change.

The simple scheme works mainly because of the PORTA pins going to the high impedance state with the falling edge

on MCLR and the possibility to ex-or the comparator output with a user defined bit value.

The serial line is planned mainly for sniffing and monitoring purpose.

Details on how the particular firmware employs the serial line can be found in the particular source code comments…

Crypto1 enhancement

To support MIFARE Classic attacks on schemes relying both on UID and crypto memory access,

the version with Crypto1 coprocessor support is currently under construction.

The coprocessor itself is a (V)HDL design (many thanks to Jiri Bucek <jiri_dot_bucek (at) fit_dot_cvut_dot_cz> for his vital help and patience)

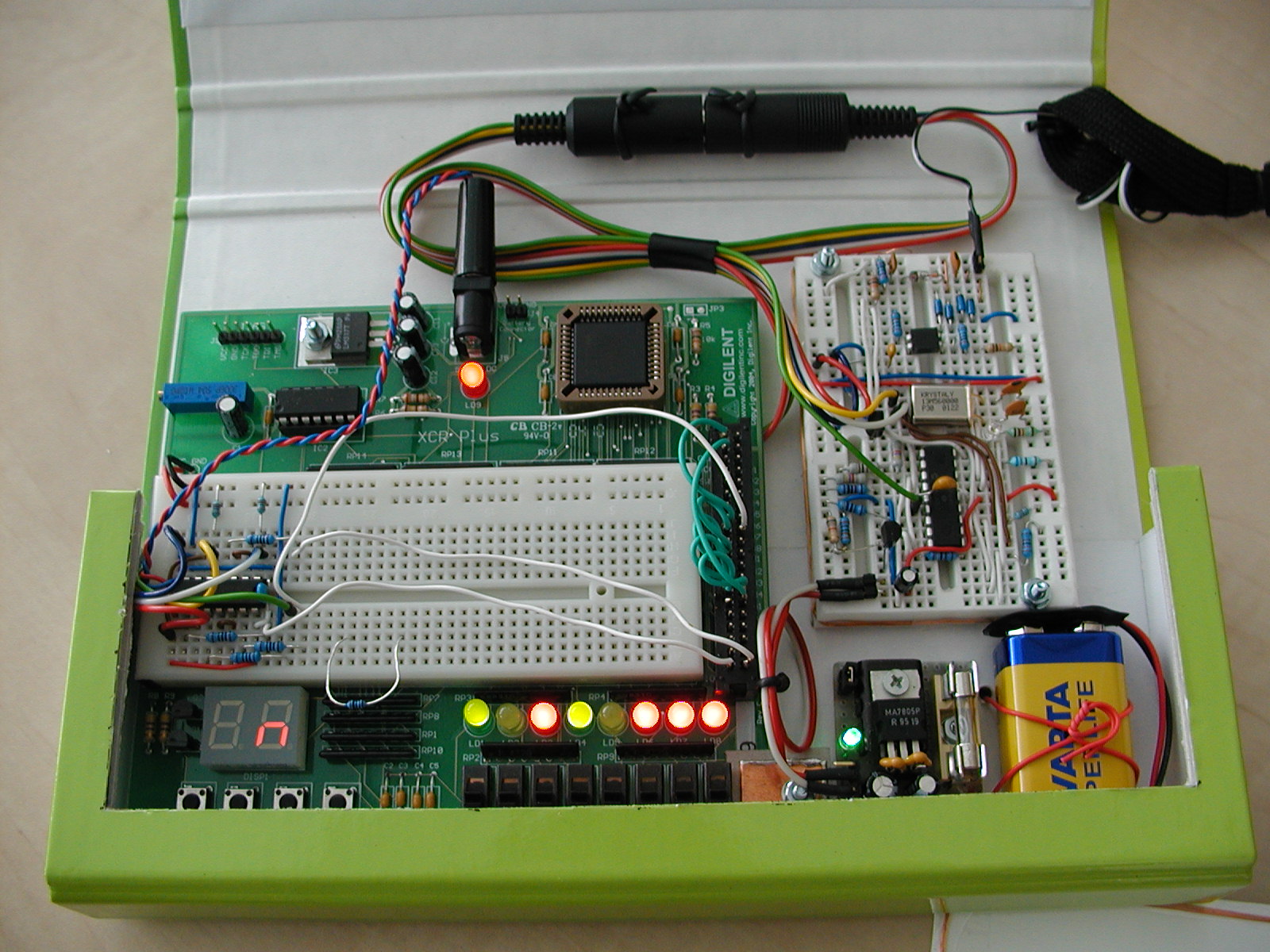

targeted for a simple CPLD devices. In particular, the (a bit obsolete)Digilent’s Digilab XCRP circuit board featuring the Xilinx XCR3064XL is used, now.

Current status of the project:

- VHDL design: OK

- VHDL testbench: OK

- PicNic interconnection: OK

- Key load procedure: OK

- UID and n_T load procedure: OK

- MIFARE Classic login procedure: OK

- MIFARE Classic simple read procedure: OK

- Access control reader protocol: sometimes fails – to be further tested

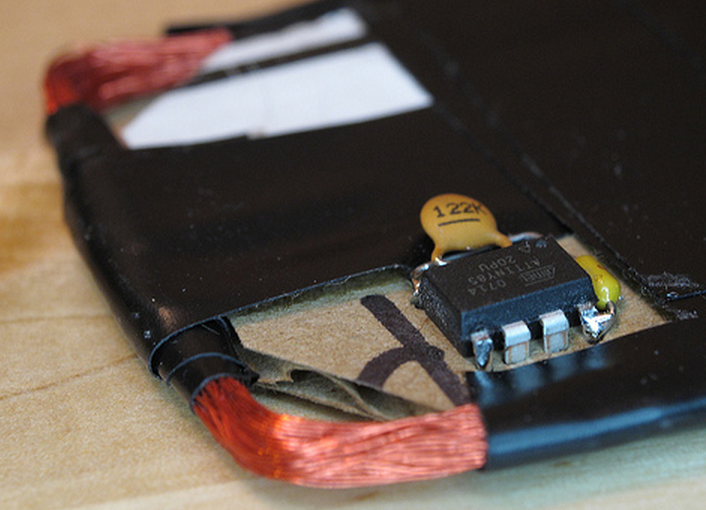

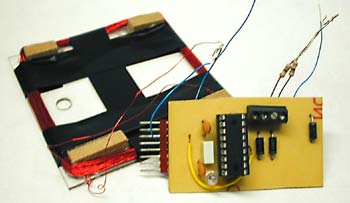

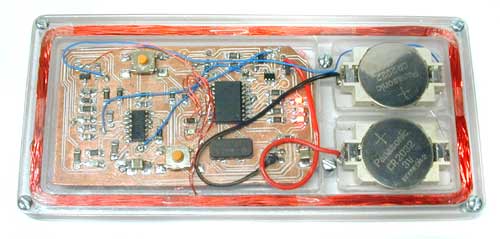

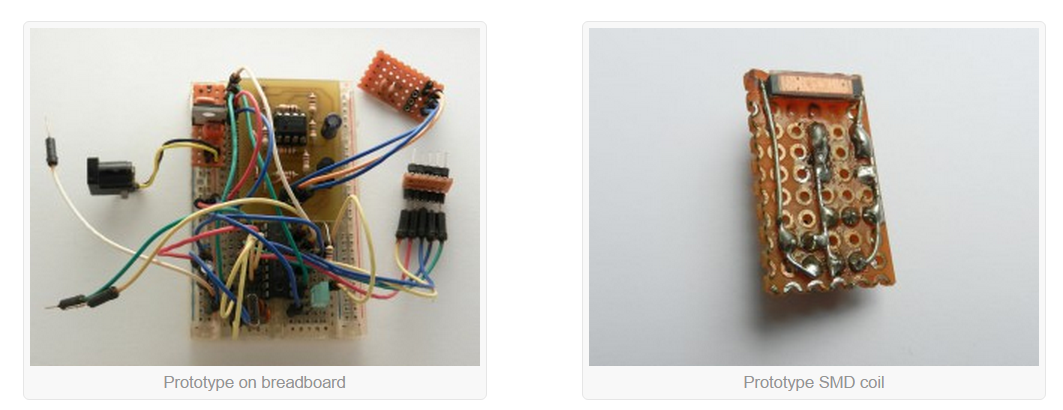

Some pictures of the whole prototype design can be found here:

device detail, inner side, outer box.

ALPHA codes snapshot - just to get an idea (interconnection with CPLD can be derived from the sources).

http://crypto.hyperlink.cz/files/FakeUIDCrypto_1_0_alpha.zip

(Ab)Using the NFC-WI/S2C interface (SAM-PicNic)

This interface is supported by several NFC front ends of NXP, mainly by the PN511 and PN512.

Note that these chips are also embedded in the PN531, PN532, and PN533 controllers,

since those devices are in fact composed of PN511 (or PN512) plus certain 80C51-based microcontroller core.

The NFC-WI/S2C interface main purpose is to allow using the core analog Tx/Rx path for attaching the so-called Secure Module (SAM).

The Secure Module can be, for instance, a somehow stripped MIFARE Classic chip (only its digital part is used).

The interface provides mainly the following five signals: power source/reference, GND, SIGOUT, SIGIN, and SIC_CLK.

The SIGOUT is an output providing modified Miller encoded data (the particular analog signal appearance depends on the particular registry configuration of the controller). The SIGIN is an input expecting Manchester coded signal with the subcarrier of 847.5 kHz (modulation signal of the transponder). The SIC_CLK provides recovered basic carrier signal of 13.56 MHz. Some other signals can be added to this interface, provided these are useful for the specific purpose. For instance, there is the CLAD signal allowing the SAM to inform the controller about start/end of the SAM RF-activity. Details can be found in the technical documentation of NXP. It can be obtained from NXP under NDA. In time of writing this notice, however, a copy of it appeared in the doc lib at www.proxmark.org.

The idea of attaching the PicNic is that simple:

- use SIGOUT in place of the antenna/demodulator output

- use SIGIN in place of MOSFET load modulator input

- use SIC_CLK as a clock source for the PIC16F648A (as it supports external clock signal allowing even the DC idle state!); yes(!)

– the choice of designing the PicNic firmware as for the PIC having the clock signal the same as the RF basic carrier finally pays off here.

The main benefits of this setup should be:

- much better timing synchronization of the PicNic Rx and Tx (mainly the Tx-after-RX frame delay)

- possibility to simply “implant” PicNic into existing NFC devices; this could allow using existing antenna and low-level analog design as well as hiding the PicNic into, for instance, an NFC equipped mobile phone etc.

Current status of the project:

- prepare a demo board for SAM-PicNic experiments: OK

It is based on SCL3710 dongle. The interesting signals of PN531 have been drawn outside the original PCB layout. Cf. overall demo board design or SCL3710 interconnection details. The SCL3710 is driven by the libnfc library via USB channel.

- research the interconnection details: to be done (basing on the demo board measurements)

- redesign PicNic fw (minor changes are expected): to be done

- verify the real PicNic implantation: to be done

SW modules

FakeUID 1.3.2 – emulator of ISO14443A anticollison handshake for 4 bytes long UID. Certain support for data gathering for MIFARE Classic cryptanalysis is also added (see comments in the source code).

FakeUID 1.4-beta – supports ISO14443A UID of all lengths (4/7/10 bytes) and presents a redesigned Tx synchronization to allow easier application protocol extension (see comments in the source code).

FakeUID 1.4 – final version, minor changes done and some bugs corrected.

FakeUID 1.5-beta – adds a better support for the DESFire emulation. Allows capturing of terminal response for the Authenticate command. This enables offline key guessing attacks. Furthermore, it adds support for the R(NAK) – R(ACK) ping-pong which is used by some readers (e.g. CardMan 5321) to check the presence of a transponder in the terminal field. The ATS support is added as well.

FakeUID 1.5-beta OpenCard Special Edition –

the exact experimental version employed for OpenCard partial emulation in applications relaying only on static transponder data (mainly UID).

Surprisingly, such applications were already found!

This firmware was used to show that building security of RFID applications on UID-only approach is really very, very bad idea.

The whole story (in Czech) is captured here. Some technical details were discussed in this lecture (CZ).

Recommended reading

[1] Finkenzeller K.: RFID Handbook, John Wiley & Sons Ltd., 2nd edition, 2004

[2] Lee, Y.: Antenna Circuit Design for RFID Applications, Microchip Tech. Inc., 2003

[3] PIC16F627A/628A/648A Data Sheet, Microchip Tech. Inc., 2007

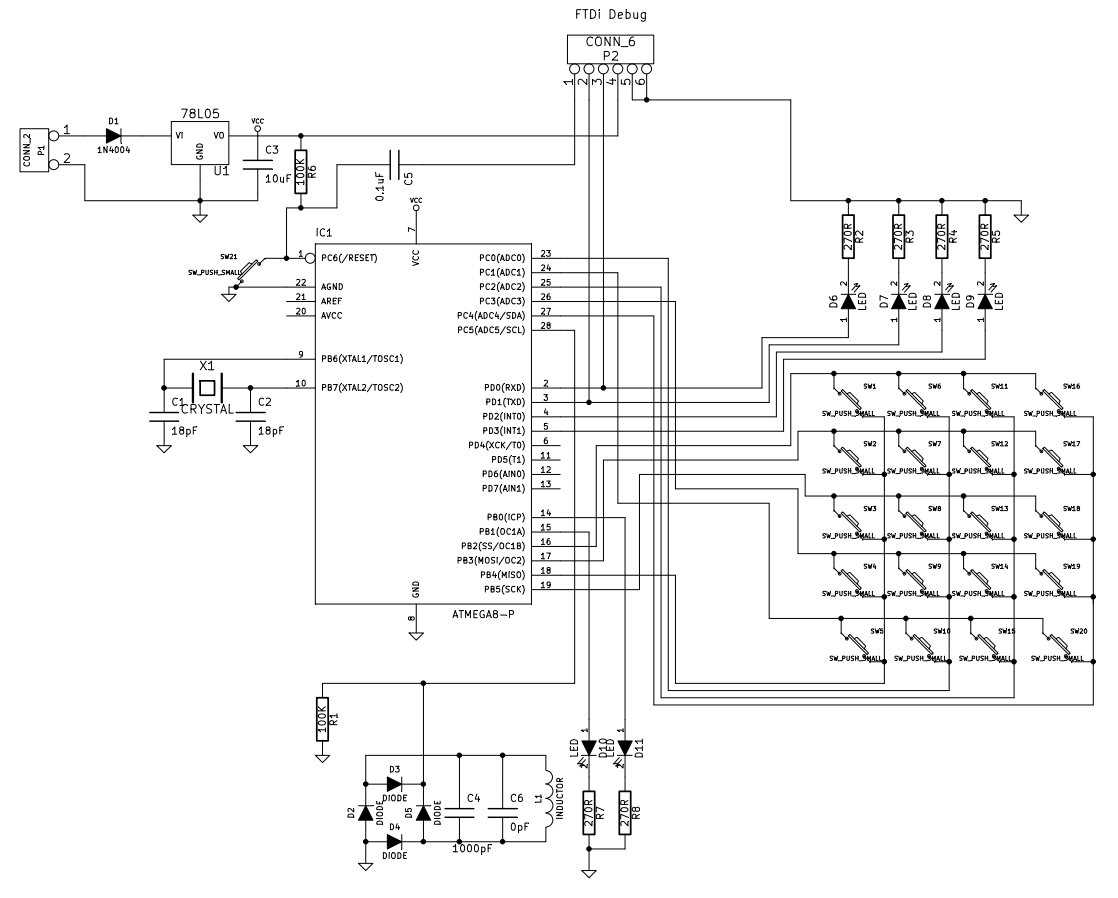

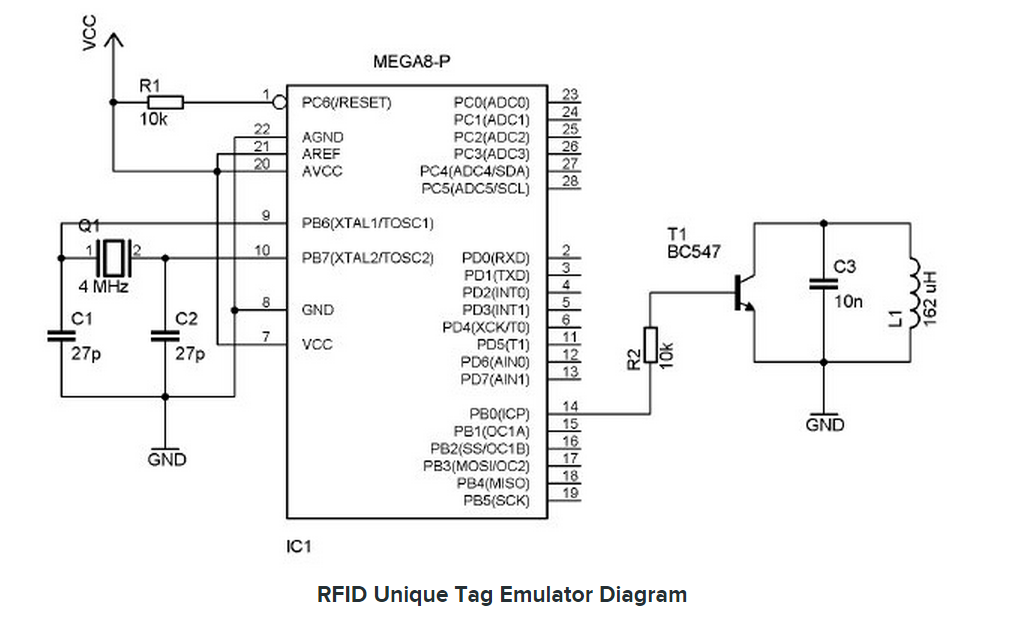

USING AN AVR AS AN RFID TAG

Experiments in RFID, continued…

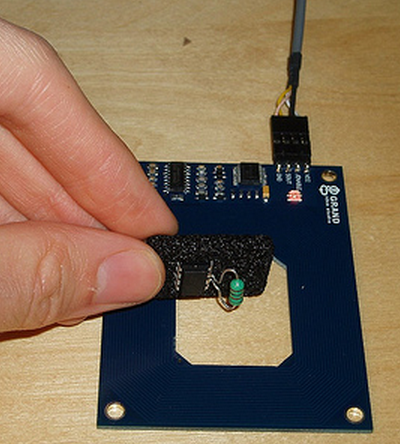

Last time, I posted an ultra-simple “from scratch” RFID reader, which uses no application-specific components: just a Propeller microcontroller and a few passive components. This time, I tried the opposite: building an RFID tag using no application-specific parts.

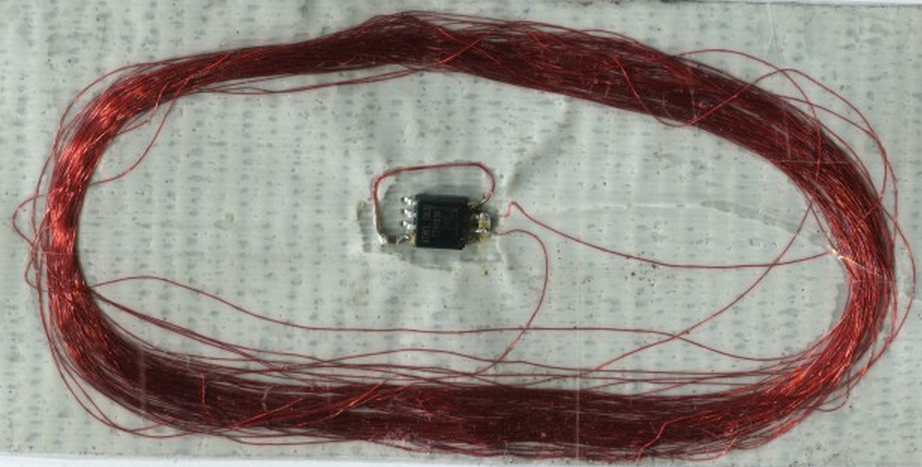

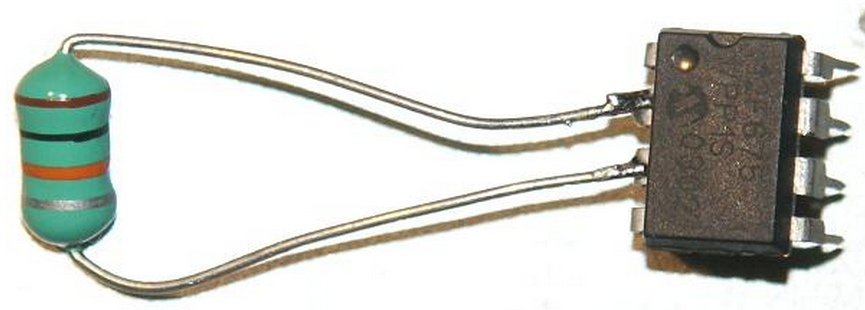

Well, my solution is full of dirty tricks, but the results aren’t half bad. I used an Atmel AVR microcontroller (the ATtiny85) and a coil. That’s it. You can optionally add a couple of capacitors to improve performance with some types of coils, but with this method it’s possible to build a working RFID tag just by soldering a small inductor to an AVR chip:

The above prototype emulates an EM4102-style tag- a very popular style of low-frequency RFID tag which stores a 40-bit unique ID. I can read my bogus ID value (0x12345678AB) using Parallax’s RFID reader. Below is another prototype, with a larger coil and a couple of capacitors for added range and stability. It is programmed to emulate a HID prox card, a simple FSK-modulated tag with a 44-bit payload. I can read this card successfully with my garage door opener. This one is a little large to conveniently carry around, but a smaller AVR package should help.

So, the shiny electrical tape is beautiful, but how does this thing even work? The power pins on the microcontroller aren’t even connected!

As I said, this makes use of several dirty tricks:

- The coil actually powers the AVR through two of its I/O pins. Nearly every chip out there has clamping diodes on its I/O pins, which prevent voltages on that pin from rising above the chip’s supply voltage or sinking below ground. These diodes are useful for arresting static discharge.When you first hold the RFID tag up to a reader, the chip has no power- the supply voltage is zero. When the coil starts to pick up power from the RFID reader, these two I/O pins are presented with a sine wave, a few volts in amplitude. Anywhere that sine wave exceeds the supply voltage, some energy is diverted from the coil to the chip’s supply rails, via the clamping diode. The end result is that the chip is powered, and the coil’s sine wave is truncated. The top and bottom of the sine have been chopped off, and it looks a lot more like a square wave now.

- Power filtering using the AVR’s die capacitance. In the smaller prototype, there is no power filtering capacitor at all. In fact, the power is filtered by the internal capacitance of the power planes in the AVR’s silicon die. This isn’t much, but it makes the power supply stable enough that we can execute code even though the supply is pulsing at 125 kHz.

- Very low voltage operation. This particular ATtiny85 chip is specified for operation at voltages as low as 2.5v. The extended voltage range version (I didn’t have any of these handy) is specified down to 1.8v. But I’m running these AVRs at barely over 1 volt. At these voltages, the normal AVR clock oscillators don’t work- but I can get away with this because of the next hack…

- The coil is the AVR’s clock source. The inductor isn’t just hooked up to any I/O pin: it’s actually connected to the AVR’s clock input. Remember the square-ish wave we’re left with after the clamping diodes suck away some power? That waveform is now our clock input. The microcontroller is executing code at 125 kHz, in lockstep with the RFID reader’s carrier wave.

- Firmware? What firmware? At such low speeds, the chip’s firmware looks less like a program, and more like a sequence of I/O operations to perform in sync with each carrier clock cycle. There aren’t a lot of cycles to spare. In the EM4102 protocol, you could potentially do some useful work with the 32 clock cycles you have between each bit. With the HID protocol, though, you need to output an FSK edge as often as once every 4 clock cycles. As a result, the firmware on the RFID tag is extremely dumb. The “source code” is really just a set of fancy assembler macros which convert an RFID tag code into a long sequence of I/O instructions.

The fact that this thing works at all is quite a testament to the robust design of the AVR. The latest AVRFID source is in Subversion, as usual.

/*

* Software-only implementation of a passive low-frequency RFID tag,

* using an AVR microcontroller.

*

* Version 1.1, 2010-06-15

*

* Copyright (c) 2008-2010 Micah Dowty <micah@navi.cx>

* See end of file for license terms. (BSD style)

* Improved HID modulation contributed by Luke Koops <luke.koops@gmail.com>

* HID parity bit support contributed by Cesar Fernandez <cex123@gmail.com>

*

* Supports EM4102-style tags, and the HID 125 kHz prox card protocol.

* The card format and ID number are set below, with #defines.

*

* Basic schematic:

*

* ATtiny85

* +--------------+

* --| RST Vcc |--

* +- L1 ----| B3/CLKI SCK |--

* +---------| B4 MISO |--

* --| GND MOSI |--

* +--------------+

*

* L1 is about 1 mH. It and the AVR are the only components.

* All other pins should be unconnected.

*

* AVR notes:

*

* - Low-voltage parts are better, but I've had success using

* this with the non-extended voltage range parts as well.

*

* - Program the fuses for an external clock with no divider.

* On the ATtiny85, this means setting lfuse to 0xC0.

* Note that after you set this fuse, your programmer will

* need to supply a clock on pin 2 for subsequent programming

* operations.

*

* Optional parts:

*

* - Power decoupling capacitor, between 0.1 and 10uF.

* Bigger is generally better, as it will increase the

* usable range- but if you use this tag with readers that

* have a pulsed carrier wave, bigger caps may take too long

* to charge.

*

* - A load capacitor, in parallel with L1. This will depend

* on your coil. For physically small coils, the internal

* capacitance of the AVR seems to be enough. For larger coils,

* it may be necessary to use a cap here. Experiment to find the

* best value.

*

* - A header, for in-circuit programming. You'll need to expose nearly

* every pin on the chip, since the AVR will also need an external

* clock.

*

* - If you want to make an active (powered) tag, you could hook a 3V

* battery up to the Vcc and GND pins on the AVR. To decrease the power

* usage when idle, you may want to hook a large (a couple megohm)

* pull-down resistor to the clock input, to be sure CLKI doesn't float

* when there is no RF field present.

*

* Theory of operation:

*

* Like all passive RFID tags, this circuit is powered by the 125 kHz

* carrier wave emitted by the RFID reader. In our case, the coil is

* just connected to two AVR I/O pins. We're actually powering the AVR

* through its protective clamping diodes, and the power is retained by

* the AVR die's internal capacitance.

*

* This is a very weak power source, and the AVR typically gets little

* over a volt of Vcc. As a result, most of the AVR's oscillators won't

* start. We can, however, use the carrier wave itself as a clock as well.

* This also makes the software easy, since the instruction clock is also

* the RF clock. We're already clamping the coil voltage into something

* resembles a square wave, so this makes a good external clock source.

*

* To send data back to the reader, passive RFID tags can selectively

* attenuate the reader's carrier wave. Most RFID tags do that with a

* transistor which shorts their coil. We accomplish this by driving the

* coil I/O pins to ground, by toggling the DDRB register. Since the I/O

* drivers on the AVR are weaker than the RF signal, we still get enough

* of a pulse to provide the CLKI input.

*

* And that's about all there is to it. The software is quite simple- we

* are mostly just using assembler macros to convert the desired RFID tag

* code into sequences of subroutine calls which output bits. We can't

* get too fancy with the software, since it's only executing at 125 kHz.

*

*/

/************ Configuration *****************************************/

// Uncomment exactly one format:

#define FORMAT_IS_EM4102

//#define FORMAT_IS_HID

// For the EM4102: An 8-bit manufacturer ID and 32-bit unique ID.

#define EM4102_MFR_ID 0x12

#define EM4102_UNIQUE_ID 0x3456789A

/*

* For the HID card:

* A 20-bit manufacturer code, 8-bit site code, and 16-bit unique ID, 1-bit odd parity.

*

* Manufacturer code is fixed. If modified, HID readers do not recognise the tag.

* (This may also be a kind of fixed header.) Tested on HID readers with 26-bit wiegand output.

*/

#define HID_MFG_CODE 0x01002 // Do not modify

#define HID_SITE_CODE 0x9F

#define HID_UNIQUE_ID 1326 // May be written on the back of the card

/************ Common ************************************************/

#ifndef __ASSEMBLER__

#define __ASSEMBLER__

#endif

#include <avr/io.h>

.global main

#define OUT_PINS _BV(PINB3) | _BV(PINB4)

.macro delay cycles

.if \cycles > 1

rjmp .+0

delay (\cycles - 2)

.elseif \cycles > 0

nop

delay (\cycles - 1)

.endif

.endm

.macro manchester bit, count=1

.if \count

manchester (\bit >> 1), (\count - 1)

.if \bit & 1

baseband_1

baseband_0

.else

baseband_0

baseband_1

.endif

.endif

.endm

.macro stop_bit

baseband_0

baseband_1_last

.endm

/************ EM4102 Implementation *********************************/

/*

* The common EM4102 cards use Manchester encoding, at a fixed rate of

* 64 RF clocks per bit. This means 32 clock cycles per half-bit (baseband

* code). There are a total of 64 manchester-encoded bits per packet. 40

* of these are payload, 9 bits are header (all ones) and one bit is a stop

* bit (zero). All other bits are parity, with one row parity bit every

* 4 bits, and four column parity bits at the end of the packet.

*/

#ifdef FORMAT_IS_EM4102

#define ROW_PARITY(n) ( (((n) & 0xF) << 1) | \

(((n) ^ ((n) >> 1) ^ ((n) >> 2) ^ ((n) >> 3)) & 1) )

#define COLUMN_PARITY ( (EM4102_MFR_ID >> 4) ^ \

(EM4102_MFR_ID) ^ \

(EM4102_UNIQUE_ID >> 28) ^ \

(EM4102_UNIQUE_ID >> 24) ^ \

(EM4102_UNIQUE_ID >> 20) ^ \

(EM4102_UNIQUE_ID >> 16) ^ \

(EM4102_UNIQUE_ID >> 12) ^ \

(EM4102_UNIQUE_ID >> 8) ^ \

(EM4102_UNIQUE_ID >> 4) ^ \

(EM4102_UNIQUE_ID) )

main:

.macro baseband_0

rcall baseband30_0

rjmp .+0

.endm

.macro baseband_1

rcall baseband30_1

rjmp .+0

.endm

.macro baseband_1_last

rcall baseband30_1

rjmp main

.endm

.macro header

manchester 0x1FF, 9

.endm

header

manchester ROW_PARITY(EM4102_MFR_ID >> 4), 5

manchester ROW_PARITY(EM4102_MFR_ID >> 0), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 28), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 24), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 20), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 16), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 12), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 8), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 4), 5

manchester ROW_PARITY(EM4102_UNIQUE_ID >> 0), 5

manchester COLUMN_PARITY, 4

stop_bit

/*

* Emit a 0 at the baseband layer.

* Takes a total of 30 clock cycles, including call overhead.

*/

baseband30_0:

ldi r16, OUT_PINS // 1

rjmp baseband30 // 2

/*

* Emit a 1 at the baseband layer.

* Takes a total of 30 clock cycles, including call overhead.

*/

baseband30_1:

ldi r16, 0 // 1

rjmp baseband30 // 2

/*

* Internal routine for baseband32_0 and _1. Must use

* a total of 24 clock cycles. (32 - 1 ldi - 2 rjmp - 3 rcall)

*/

baseband30:

out _SFR_IO_ADDR(DDRB), r16 // 1

delay 19 // 19

ret // 4

#endif /* FORMAT_IS_EM4102 */

/************ HID Implementation *********************************/

/*

* This works with the HID 125 kHz prox cards I've tested it with,

* but there are undoubtedly other formats used by HID. My cards are

* marked with the model number "HID 0004H".

*

* These cards use both manchester encoding and FSK modulation. The FSK

* modulation represents zeroes and ones using 4 and 5 full RF cycles, respectively.

* An entire baseband bit lasts 50 RF cycles.

*

* Each packet begins with a header consisting of the baseband bit pattern "000111".

* After that, we have 45 manchester-encoded bits before the packet repeats. The

* last bit appears to be a stop bit, always zero. The previous 20 bits encode the

* 6-digit unique ID, which is printed on the back of the card. The other 24 bits

* have an unknown use. They could be a site code or manufacturing code. In the cards

* I've examined, these bits are constant.

*/

#ifdef FORMAT_IS_HID

#define ODD_PARITY(n) ((( ((n) >> 0 ) ^ ((n) >> 1 ) ^ ((n) >> 2 ) ^ ((n) >> 3 ) ^ \

((n) >> 4 ) ^ ((n) >> 5 ) ^ ((n) >> 6 ) ^ ((n) >> 7 ) ^ \

((n) >> 8 ) ^ ((n) >> 9 ) ^ ((n) >> 10) ^ ((n) >> 11) ^ \

((n) >> 12) ^ ((n) >> 13) ^ ((n) >> 14) ^ ((n) >> 15) ^ \

((n) >> 16) ^ ((n) >> 17) ^ ((n) >> 18) ^ ((n) >> 19) ^ \

((n) >> 20) ^ ((n) >> 21) ^ ((n) >> 22) ^ ((n) >> 23) ^ \

((n) >> 24) ^ ((n) >> 25) ^ ((n) >> 26) ^ ((n) >> 27) ^ \

((n) >> 28) ^ ((n) >> 29) ^ ((n) >> 30) ^ ((n) >> 31) ) & 1) ^ 1)

main:

eor r16, r16

ldi r17, OUT_PINS

loop:

/*

* Toggle the output modulation, in the specified number

* of total clock cycles.

*/

.macro toggle clocks

delay (\clocks - 2)

eor r16, r17

out _SFR_IO_ADDR(DDRB), r16

.endm

/*

* Emit a 0 at the baseband layer. (Toggle every 4 cycles, for 50 cycles)

* There was an rjmp that got us to the beginning of the loop, so drop

* 2 cycles from the delay if this is the first bit. That will give the

* appropriate delay before the toggle.

*

* From observing the HID card, each 0 bit is either 48 or 52 cycles.

* The length alternates to keep the average at 50. This keeps the

* waveform smooth, and keeps each bit in its 50 cycle time slot.

*

* We don't have time for a function call, so we just chew

* up lots of flash...

*/

.macro baseband_0

.if startloop

toggle 2 // 4

.equ startloop, 0

.else

toggle 4 // 4

.endif

toggle 4 // 8

toggle 4 // 12

toggle 4 // 16

toggle 4 // 20

toggle 4 // 24

toggle 4 // 28

toggle 4 // 32

toggle 4 // 36

toggle 4 // 40

toggle 4 // 44

toggle 4 // 48

.if evenzero

.equ evenzero, 0

.else

toggle 4 // 52

.equ evenzero, 1

.endif

.endm

/*

* Emit a 1 at the baseband layer. (Toggle every 5 cycles, for 50 cycles)

*/

.macro baseband_1

.if startloop

toggle 3 // 4

.equ startloop, 0

.else

toggle 5 // 4

.endif

toggle 5 // 10

toggle 5 // 15

toggle 5 // 20

toggle 5 // 25

toggle 5 // 30

toggle 5 // 35

toggle 5 // 40

toggle 5 // 45

toggle 5 // 50

.endm

.macro header

.equ evenzero, 0

.equ startloop, 1

baseband_0

baseband_0

baseband_0

baseband_1

baseband_1

baseband_1

.endm

/*

* This should add up to 45 bits.

*

* Some cards may use different 45-bit codes: For example,

* a Wiegand code, or something more site-specific. But the

* cards that I've seen use a 20-bit manufacturer code,

* 8-bit site code, 16-bit unique ID, and a single parity bit.

*

* If your card uses ad ifferent coding scheme, you can add,

* remove, and modify these 'manchester' macros. Just make sure

* the result adds up to the right number of bits.

*/

header

manchester HID_MFG_CODE, 20

manchester HID_SITE_CODE, 8

manchester HID_UNIQUE_ID, 16

manchester ODD_PARITY(HID_MFG_CODE ^ HID_SITE_CODE ^ HID_UNIQUE_ID), 1

rjmp loop

#endif /* FORMAT_IS_HID */

/*****************************************************************/

/*

* Permission is hereby granted, free of charge, to any person

* obtaining a copy of this software and associated documentation

* files (the "Software"), to deal in the Software without

* restriction, including without limitation the rights to use,

* copy, modify, merge, publish, distribute, sublicense, and/or sell

* copies of the Software, and to permit persons to whom the

* Software is furnished to do so, subject to the following

* conditions:

*

* The above copyright notice and this permission notice shall be

* included in all copies or substantial portions of the Software.

*

* THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND,

* EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES

* OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

* NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT

* HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY,

* WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING

* FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR

* OTHER DEALINGS IN THE SOFTWARE.

*/

AVR RFID, OPTIMIZED AND PORTED TO C

Way back in 2008, I posted a writeup about using an AVR microcontroller as an RFID tag. Since then, it’s been great to see many people pick up this code and build their own DIY RFID tags.

In my original project, I was just interested in using an AVR as a way of emulating any tag protocol I wanted, even proprietary protocols like the HID cards that are so common for door entry. But a general purpose microcontroller really lends itself to making even more interesting tags. For example, imagine an action figure that has different poses which trigger microswitches that can be read by the AVR. It could report a different RFID code depending on which pose the action figure is in. This kind of very low-power physical computing is really interesting to me.

Trammell Hudson recently took a big step in this direction, in the name of creating a “multipass” card which could stay in his pocket and pretend to be any number of other cards. His original idea didn’t quite work out, due to limitations in the HID readers. But along the way, he created an optimized version of the AVRFID firmware which uses much less flash memory, and he ported it to C so that it can be more easily extended and modified.

He made this posible by very carefully choosing the instructions in the inner loops, creating a state machine that just barely fits within the available clock cycles:

One issue with programming HID Prox compatible cards is that the AVR’s RCALL and RET instructions are quite slow — 3 and 4 clocks respectively — so making a function call and returning from it requires seven clocks and would cause errors in the RF waveform. To get around this, Beth expanded all of the code inline to produce a single function that bit-bangs the coil loading with NOP‘s between each cycle. The 20-bit manufacturer ID (0x01002), 8-bit faciity code and 16-bit unique ID, all Manchester encoded, required 80 instructions per bit for a total of 3700 instructions out of the Tiny85′s maximum of 4096. Supporting 34-bit cards would not be possible with this design, much less multiple card IDs!

While RCALL/RET are out of the question, I noticed that IJMP is only 2 clocks. This means that the CPU can do an indirect jump to the value in the 16-bit Z register in enough time to be ready for the next FSK cycle. If we know where to go, that is… The LPM instruction takes three cycles to read a byte from flash into a register, which just barely fits during the idle time during a FSK baseband one. Loading the Z register for LPM takes at least two clocks (since it is really the two 8-bit registers r31:r30), which means the pgm_read_word() macro in avr/progmem.h won’t work. While the rest of the firmware is in mostly normal C, I resorted to writing assembly to interleave the coil toggling with the operations to determine the next output state and make the appropriate jump. If you want to follow along, the source for the RFID firmware is available in rfid/avrfid2.c.

His post covers a lot of ground, including how to connect an off-the-shelf HID card reader to a computer, and how to repeatedly program the AVR using a Bus Pirate.

Go check out the full article already!

/** \file

* AVR RFID card.

*

* Based on avrfrid.S by Beth at Scanlime.

* http://scanlime.org/2008/09/using-an-avr-as-an-rfid-tag/

*

* Normal C code doesn't really work here since we are limited to

* very small number of cycles per bit. The HID Prox cards are

* FSK modulated with only four or five RF cycles per baseband cycle.

* Since the AVR RCALL and RET instructions take four clocks each

* we would miss all of our timing constaints if we tried to make those calls.

*

* However, the IJMP only takes 2 clock cycles, so we can build a state

* machine and use it to make "function calls". LPM also takes three

* clocks, so we can't load a full address and jump to it within the

* timing constraint, but we can split these operations across the

* ten 5-cycle transitions during sending a baseband 1.

*

* Each of these transitions takes 2 cycles for the XOR and OUT to

* set the state, which leaves three cycles for our work.

*

* when programming with buspirate (wire/clip):

*

* White/white Reset 1 v 8 Vcc Red

* Blue/Blue Xtal1 2 7 SCK Purple/green

* Xtal2 3 6 MISO Black/Black

* Black Gnd 4 5 MOSI Gray/Yellow

*

*/

#include <avr/io.h>

#include <avr/pgmspace.h>

#include <avr/sfr_defs.h>

static void manchester_0(void);

static void manchester_1(void);

static void hid_header(void);

static void hid_reset(void);

//int main(void);

#define HID_MFG_CODE 0x01002 // Do not modify

#define HID_SITE_CODE 42

#define HID_UNIQUE_ID 23946 // May be written on the back of the card

#define HID_HEADER "2"

#define HID_RESET "3"

static const char hid_bits[]

PROGMEM __attribute__((__used__)) = {

#if 1

HID_HEADER

"0000"

"0001"

"0000"

"0000"

"0010" // HID Manufacturer code 0x01002 for n1002 cards?

"00101010" // Site code 42

"01011101"

"10001010" // ID 23946

"0" // parity

#else

HID_HEADER

"0001"

"0000"

"0000"

"0000"

"0010" // HID Manufacturer code, trying 10002 for 34-bit?

"00000000" // fc-12

"00001100"

"00111000" // id 14371

"00100011"

"0"

#endif

HID_RESET

};

typedef void (*state_function)(void);

static const state_function state_handlers[]

PROGMEM __attribute__((__used__)) = {

manchester_0,

manchester_1,

hid_header,

hid_reset,

};

#if 0

// HID manufacturer code (20 bits) == 0x01002

_0, _0, _0, _0,

_0, _0, _0, _1, _0, _0, _0, _0,

_0, _0, _0, _0, _0, _0, _1, _0,

// Facility code (8 bits) == 42

_0, _0, _1, _0, _1, _0, _1, _0,

// ID (16 bits) == 23946

_0, _1, _0, _1, _1, _1, _0, _1,

_1, _0, _0, _0, _1, _0, _1, _0,

// Parity

_0,

// And return to the header when we're done

hid_header

};

#endif

/** Use r16 and r17 to track the state of the pins.

*

* These are hard coded in toggle_raw().

*/

volatile register uint8_t r16 __asm__("r16");

volatile register uint8_t r17 __asm__("r17");

/** r15 tracks which bit are we currently sending.

*

* This is hard coded in hid_header().

*/

volatile register uint8_t bit_num __asm__("r15");

/** Jump to what ever has been stored into Z (r31:r30)

*

* PC <- Z

* 2 clocks

*/

static inline void

__attribute__((__noreturn__))

ijmp(void)

{

__asm__ __volatile__("ijmp");

while(1); // make gcc happy

}

/**

* Delay a specific number of clock cycles.

*

* rjmp is 2 clocks, nop is 1.

*

* So do one nop if the delay is an odd value and then rjmp's for n/2

* to maximize code density. Doesn't matter for the state machine version,

* but otherwise the straight-code version would overflow the 8 KB space.

*/

static inline void

__attribute__((__always_inline__))

delay(

const uint8_t n

)

{

switch (n/2)

{

case 8: asm("rjmp .+0");

case 7: asm("rjmp .+0");

case 6: asm("rjmp .+0");

case 5: asm("rjmp .+0");

case 4: asm("rjmp .+0");

case 3: asm("rjmp .+0");

case 2: asm("rjmp .+0");

case 1: asm("rjmp .+0");

case 0: break;

}

if (n % 2 == 1)

asm("nop");

}

/** Toggle the output pins to change the coil state.

*

* The DDRB pins are used to short the coil, which causes

* an increase in current draw at the reader.

*

* 2 clocks.

*/

asm(

".macro toggle\n"

"eor r16, r17\n"

"out 0x17, r16\n" // _SFR_IO_ADDR(DDRB)

".endm\n"

);

static void

__attribute__((__always_inline__))

toggle_raw(void)

{

__asm__ __volatile__("toggle");

}

/** Toggle the state of the output pins and delay for some clocks.

*

* The toggle_raw() takes 2 clocks, so we delay for the remainder.

*/

static void

__attribute__((__always_inline__))

toggle(

const uint8_t n

)

{

toggle_raw();

if (n > 2)

delay(n-2);

}

#define ZERO_FREQ 4

#define ONE_FREQ 5

/** Send a 0 at the baseband layer.

*

* If delay_slot is set, the delays after the last FSK slot will not be

* done, instead allowing the caller to make use of three extra clock

* cycles for their own usage.

*/

static void

__attribute__((__always_inline__))

baseband_0(

uint8_t delay_slot

)

{

toggle(ZERO_FREQ); // 4

toggle(ZERO_FREQ); // 8

toggle(ZERO_FREQ); // 12

toggle(ZERO_FREQ); // 16

toggle(ZERO_FREQ); // 20

toggle(ZERO_FREQ); // 24

toggle(ZERO_FREQ); // 28

toggle(ZERO_FREQ); // 32

toggle(ZERO_FREQ); // 36

toggle(ZERO_FREQ); // 40

toggle(ZERO_FREQ); // 44

toggle(delay_slot ? ZERO_FREQ : 0); // 48

}

/** Send a 1 at the baseband layer.

*

* This is only used by the header during setup since it must send

* several 1 bits in a row. Only the last one computes the next state.

* There are no delay slots following this function.

*/

static void

__attribute__((__always_inline__))

baseband_1(void)

{

toggle(ONE_FREQ); // 5

toggle(ONE_FREQ); // 10

toggle(ONE_FREQ); // 15

toggle(ONE_FREQ); // 20

toggle(ONE_FREQ); // 25

toggle(ONE_FREQ); // 30

toggle(ONE_FREQ); // 35

toggle(ONE_FREQ); // 40

toggle(ONE_FREQ); // 45

toggle(ONE_FREQ); // 50

}

/** Send a 1 at the baseband layer.

*

* Interleaved with the FSK are the operations to load the next

* function pointer. Once the function "returns", the Z register

* will contain the address of the next function in the state machine.

*

* This was too difficult to write in C and have gcc output the correct

* stream of instructions. Instead it is in inline assembly.

* The rough translation into C:

*

* toggle 5

* z = &hid_bits[bit_num];

* toggle 10

* next_state = lpm(z);

* toggle 15

* next_state = (next_state - '0') * 2

* toggle 20

* z = &state_handlers[next_state];

* toggle 25

* next_func_lo = lpm(z++);

* toggle 30

* next_func_hi = lpm(z++);

* toggle 35

* z = next_func_hi << 8 | next_func_lo;

* toggle 40

* bit_num++;

* toggle 45

* delay

* toggle 50

* No delay (leave these free for caller)

*/

static void

__attribute__((__always_inline__))

baseband_1_load(void)

{

__asm__ __volatile__(

"toggle /* 5 */\n"

"ldi r30, lo8(hid_bits)\n"

"ldi r31, hi8(hid_bits)\n"

"add r30, %0\n"

"toggle /* 10 */\n"

"lpm r24, Z\n"

"toggle /* 15 */\n"

"ldi r30, lo8(state_handlers)\n"

"ldi r31, hi8(state_handlers)\n"

"nop\n"

"toggle /* 20 */\n"

"subi r24, '0'\n"

"lsl r24\n"

"add r30, r24\n"

"toggle /* 25 */\n"

"lpm r24, Z+\n"

"toggle /* 30 */\n"

"lpm r31, Z\n"

"toggle /* 35 */\n"

"mov r30, r24\n"

"rjmp .+0\n"

"toggle /* 40 */\n"

"inc %0\n"

"rjmp .+0\n"

"toggle /* 45 */\n"

"nop\n"

"rjmp .+0\n"

"toggle /* 50 */\n"

"/* Leave slot free */\n"

: "=r" (bit_num) // 0

);

}

/** Send the HID header start bits.

*

* The HID header is an illegal state in the Manchester encoding

* used to indicate the start of the packet.

*

* The last baseband 1 will load the first state machine function

* pointer and jump into the statemachine.

*/

static void

hid_header(void)

{

baseband_0(1);

baseband_0(1);

baseband_0(1);

baseband_1();

baseband_1();

baseband_1_load();

delay(1);

ijmp();

}

/** Output a manchester 0.

*

* Output a baseband 0, followed by a baseband 1.

* During the baseband 1 the Z register will be updated

* to contain the pointer to the next function in the state machine.

*

* After the 1, with one delay slot since ijmp() takes two clocks,

* we jump to the next state.

*/

static void

manchester_0(void)

{

baseband_0(1);

baseband_1_load();

delay(1);

ijmp();

}

/** Output a manchester 1.

*

* Output a baseband 1, followed by a baseband 0.

* During the baseband 1 the Z register will be updated

* to contain the pointer to the next function in the state machine.

*

* After the 0, with no delay slots since ijmp() takes two clocks,

* we jump to the next state.

*/

static void

manchester_1(void)

{

baseband_1_load();

delay(3); // 3 delays slots remain

baseband_0(0);

ijmp();

}

/** Restart the state machine at state 0.

*

* This must be the last state in the machine and is the first one

* called from main to kick things off.

*/

static void

hid_reset(void)

{

// We will start in state 0, so the next to read is 1

// gcc keeps optimizign writes to r15 out for some reason

__asm__ __volatile__(

"eor %0, %0\n"

"inc %0\n"

: "=r"(bit_num)

);

__asm__ __volatile__("rjmp hid_header");

}

/** Entry point at 0x0.

*

* Since we linking with -nostdlib, main needs to be at 0x0.

* The easiest way to force that with the default linker script

* is to put it in the .vectors text section.

*/

int

__attribute__((section(".vectors")))

main(void)

{

r16 = 0;

r17 = _BV(PINB3) | _BV(PINB4);

hid_reset();

/* Never returns */

}

AVR RFID Multipass

I was inspired by Beth’s avrfid.S project to try to build a replacement for the multiple HID Prox cards that I carry for work.

Her design is simultaneously a technical tour-de-force and an example of how badly we can abuse the Atmel chips.

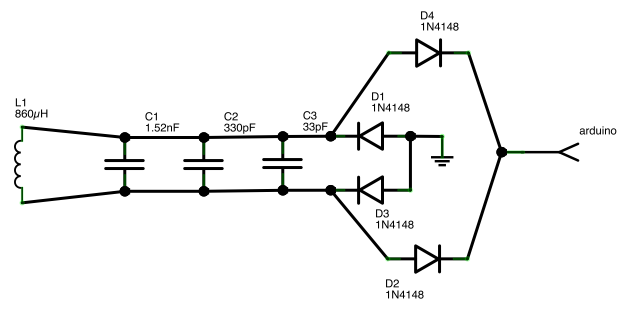

Here is the entire schematic:

There is no connection to power and ground: the chip is powered through leakage current from the input pins. The AC waveform is fed directly into the pins: the internal protection diodes rectify it. During negative parts of the wave the silicon die’s inherent capacitance maintains state. The CPU clock is driven by the AC as well and depends on the ability of the coil to drive more current than the chip when DDRB is configured to pull the pins to the same potential. It’s truly amazing that this works at all.

The firmware she wrote in macro assembler is easy to understand and straightfoward, but filled the entire 8 KB flash on the ATTiny85 when compiled for HID Prox cards.

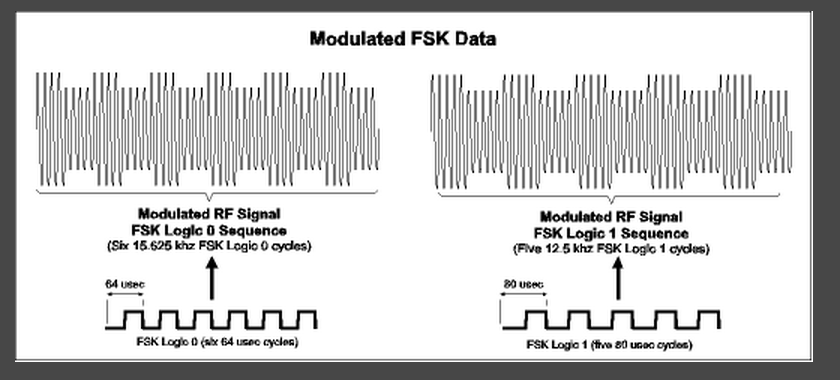

Unlike the CW modulated EM41xx cards that just load the coil for thirty RF cycles to send a baseband one and don’t load the coil to send a baseband zero, the HID cards use Frequency Shift Keying (FSK) modulation.

In FSK a baseband zero is sent by cycling the load on the coil for 50 cycles at a frequency of 4 RF cycles, and a baseband one is sent by cycling the load every 5 RF cycles. Beth’s code loads the coil by setting the two bits in DDRB to 1 while holding PORTB at 0, which places a short across the coil by putting both ends at the same potential.

While it turns out that my dream of automatically selecting the right RFID card doesn’t work, read on for details of how to build your own HID compatible RFID devices and some overview of the hand-tuned assembly necessary to fit the RFID timing.

Instruction timing

One issue with programming HID Prox compatible cards is that the AVR’s RCALL and RET instructions are quite slow — 3 and 4 clocks respectively — so making a function call and returning from it requires seven clocks and would cause errors in the RF waveform. To get around this, Beth expanded all of the code inline to produce a single function that bit-bangs the coil loading with NOP‘s between each cycle. The 20-bit manufacturer ID (0x01002), 8-bit faciity code and 16-bit unique ID, all Manchester encoded, required 80 instructions per bit for a total of 3700 instructions out of the Tiny85’s maximum of 4096. Supporting 34-bit cards would not be possible with this design, much less multiple card IDs!

While RCALL/RET are out of the question, I noticed that IJMP is only 2 clocks. This means that the CPU can do an indirect jump to the value in the 16-bit Z register in enough time to be ready for the next FSK cycle. If we know where to go, that is… The LPM instruction takes three cycles to read a byte from flash into a register, which just barely fits during the idle time during a FSK baseband one. Loading the Z register for LPM takes at least two clocks (since it is really the two 8-bit registers r31:r30), which means the pgm_read_word() macro inavr/progmem.h won’t work. While the rest of the firmware is in mostly normal C, I resorted to writing assembly to interleave the coil toggling with the operations to determine the next output state and make the appropriate jump. If you want to follow along, the source for the RFID firmware is available in rfid/avrfid2.c.

The state machine

The card IDs are stored in a flash memory character array where the ASCII characters encode the states. 2 is the state that sends the HID header, state 3 is to jump back to the start, and states 0 and 1 send a zero or one. For one of my test cards, the array definition looks like this (with __used__ to indicate to gcc that this array must be present, even if it does not see any usage of it):

static const char hid_bits[]

PROGMEM __attribute__((__used__)) =

{

"2" // HID_HEADER

"00000001000000000010" // HID code 0x01002 for n1002 cards?

"00101010" // Site code 42

"0101110110001010" // ID 23946

"0" // parity (should be a separate state)

"3" // HID_RESET

};

The code to send a baseband one looks roughly like this, with the FSK generation interleaved with reading the next state from the hid_bits[] array and then looking up the function to call from the state_handlers[]. At the end of the function, the Z register holds the function pointer to be called next. The toggle macro takes two clocks and turns the load on the coil if it is currently unloaded, or turns it off if it is currently on. This leaves three clocks to do before the next toggle. Most of the instructions are single cycle, except for LPM which is three clocks, and RJMP .+0 which is a two clock NOP.

baseband1:

toggle /* 5 */

ldi r30, lo8(hid_bits)

ldi r31, hi8(hid_bits)

add r30, r15 // bit_num

toggle /* 10 */

lpm r24, Z // next_bit = lpm(hid_bits[bitnum])

toggle /* 15 */

ldi r30, lo8(state_handlers)

ldi r31, hi8(state_handlers)

nop

toggle /* 20 */

subi r24, '0'

lsl r24

add r30, r24 // z = &state_handlers[next_bit - '0']

toggle /* 25 */

lpm r24, Z+

toggle /* 30 */

lpm r31, Z

toggle /* 35 */

mov r30, r24 // z = lpm(z);

rjmp .+0

toggle /* 40 */

inc r15 // bit_num++

rjmp .+0

toggle /* 45 */

nop // Nothing to do!

rjmp .+0

toggle /* 50 */

/* Leave last delay slot free */

Last year we wrote about building HID Proxcard RFID tags with attiny85 microcontrollers (based on Micah’s avrfid.s code). The C version only supported classic 26-bit cards, but I recently needed to support the “secure” HID Corporate 1000 35-bit format.

Based on Daniel Smith’s writeup on the format and some digging around, I figured out that the MFG_CODE for this format is 10-bits long with the value 0x005. He also pointed out that the 26-bit firmware had the wrong code — it is not the 20-bit code 0x01002, but is instead the 19-bit code 0x0801 and the bottom bit is part of the parity computation for the card id. If you’re using a HID branded Proxcard reader, the value that it outputs is the entire data portion, including all of the parity bits, but does not include the MFC_CODE part. If anyone knows of a table of these codes, please let me know!

I’ve updated my firmware with these changes and it works great. Emulating a 35-bit card takes 846 bytes of flash (nine more than the 26-bit cards since the state machine stores one bit per byte), so it might be possible to port this to the attiny10. I’ve also found that the tags work much better with a small capacitor across the two clock pins, as shown in the above photo.

AVRFID 1.1 FIRMWARE

I don’t normally write bloggy posts on every version of every source file I check in, but every so often an older project sees some more activity, and I love the opportunity to revisit software I wrote years ago. Sometimes I wonder why I wrote such-and-such thing that way and oh my god what an ugly hack. But usually it’s just refreshing to think about a problem I haven’t thought about in a while.

The AVRFID was a quick but rather unique project, back from when I was on a bit of a 125 kHz RFID binge culminating in the design, construction, and installation of a proxcard reader for my garage door. While I was fidgeting around with such things, it occurred to me that you could (using a whole host of dirty tricks) convince a general-purpose 8-bit microcontroller like the AVR to function as a passive RFID tag.

Since then, I received a couple patches:

- Luke Koops improved the FSK modulation for HID tags, so that the resulting waveform is much more regular.

- Cesar Fernandez described the HID card format in more detail, and implemented a parity calculation. The 45-bit code is actually composed of four distinct fields:

- A 20-bit manufacturer code or header, constant for all HID cards.

- An 8-bit site code, unique to the particular security installation.

- A 16-bit unique ID. These are often printed in decimal on the back of the card, and they seem roughly sequential.

- An odd parity bit, covering the other 44 bits.

I didn’t have my RFID gear handy, so Cesar was kind enough to verify it with his official HID reader. So I stamped a new version number on it. If you’re interested in building your own HID card emulator, there is now a much better chance it will actually work with your reader

- Grab the latest source code from Subversion.

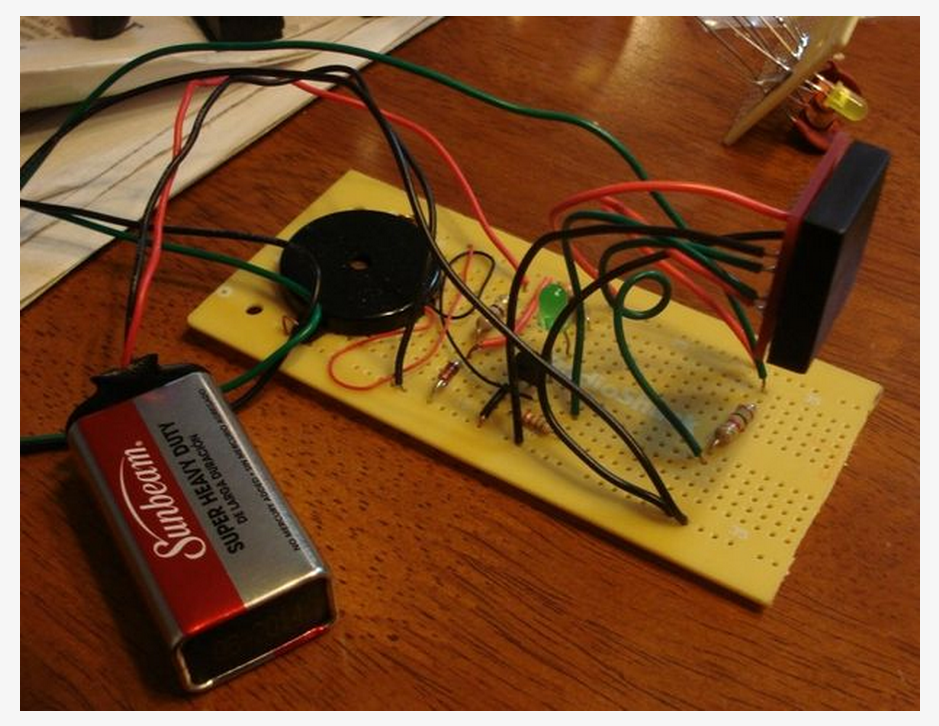

DUCT TAPE RFID TAG #1

This is just a messy first prototype, but I recently tried making an AVRFID tag on a substrate of duct tape. The first attempt involved:

- An upside-down strip of duct tape, as the base for everything else to stick atop

- 100 turns of AWG 40 magnet wire around a ~66mm diameter form, which I then haphazardly squished against the tape

- An ATtiny85 µC in the SOIC-8 package, programmed with the latest AVRFID firmware

- SMT 0.1 µF capacitor across the power pins

- SMT 1 nF capacitor in parallel with the coil, for tuning it to approximately 125 kHz

- Sealed with clear packing tape on the opposite side

It’s ugly, and I really want to try this experiment over again with a smaller IC package, like TSSOP-8. But the card works very well, and the read range is practically indistinguishable from a mass-produced RFID card. I tested this one using an official HID ProxPoint reader.

I’ve been busy, but once I have time to perfect this technique I’m hoping to write some instructions, as it’s a pretty quick and easy way to make a DIY RFID tag that’s actually in a convenient form-factor.

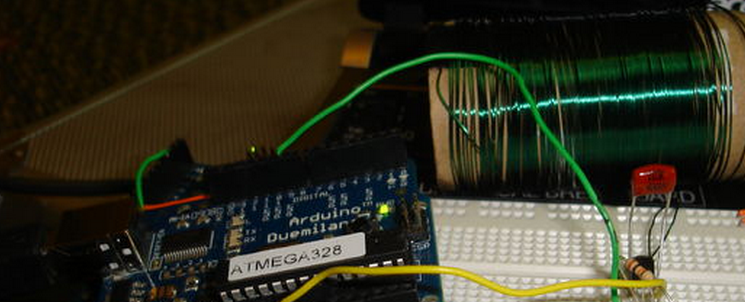

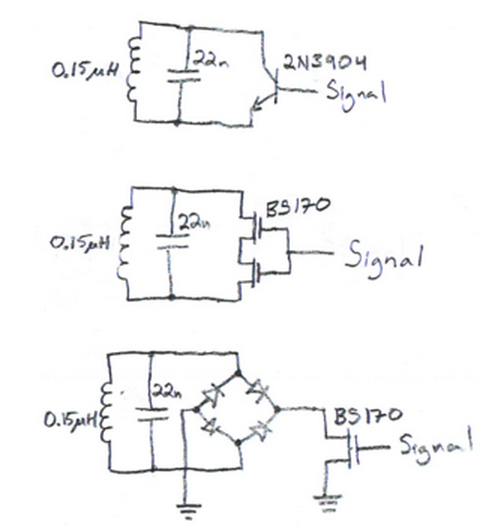

Stupid Simple Arduino LF RFID Tag Spoofer

UPDATE: Here is a link to an Arduino Mini shield based on these instructions

*Some enamel coated solid core copper wire (I used the green spool from the 3 spool set Radio Shack carries).

*A NPN transistor, I used a 2N3904

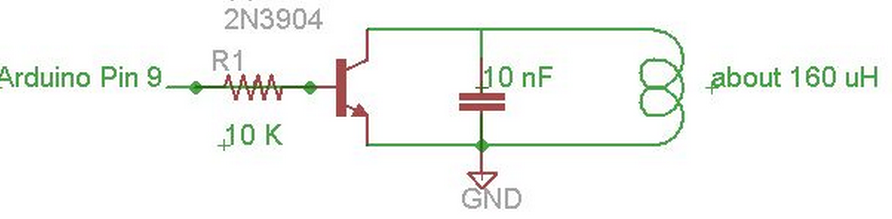

*A 10 K Ohm Resistor

*A 10 nF capacitor (0.01 uF). I'm using a Metalized polyester film cap I got from Radio Shack, others should work though

*A toilet paper roll to wind the wire on

I tested my circuit using a Parallax RFID serial reader connected to a second Arduino

After you have your coil you can connect it to your circuit. The schematic is pretty easy. Just connect pin 9 on the Arudino to a 10 K Ohm resistor, then to the base of the transistor. Next you can put your capacitor between the collector and emitter of the transistor. The emitter also needs to be connected to ground. Next connect the coil the the emitter and collector of the transistor.

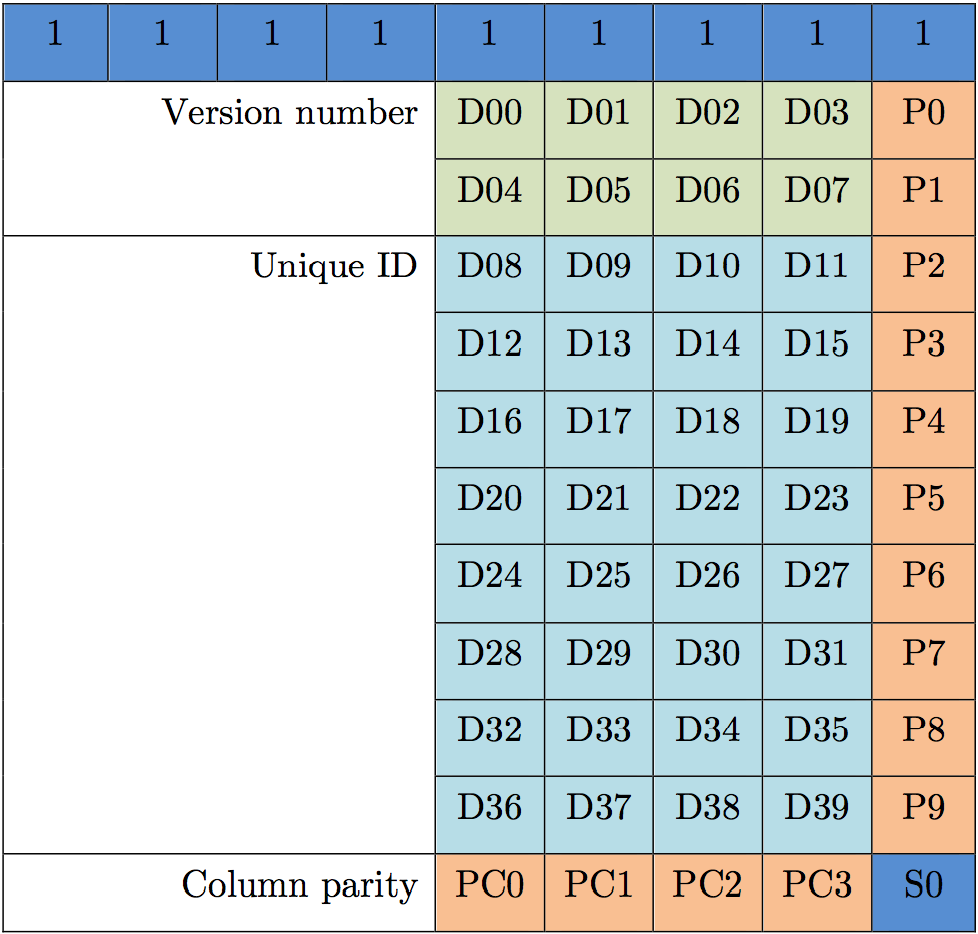

The serial number of a tag is sent over using a fairly simple protocol.

It starts by sending 9 one's

Then it sends 10 sets of 4 bits, then one parity bit (it's using even parity)

Then it sends "column" parity bits (even parity of the rows in the previous step)

Last it sends a 0 stop bit

So an example looks like this:

(start bits)

111111111

(10 rows of data - the card serial number)

(the first 4 bits are the data, the last is the even parity bit)

11110

10100

10001

11000

10010

11101

11110

00000

00011

01010

(then it sends the column parity bits, even parity of the rows above)

1101

(last a 0 stop bit)

0

See the pdf in the first link in the references section for more details on this

Image provided by Flickr user at www.flickr.com/photos/kurtisscaletta/2473469841/

//Pin to connect to the circuit

//Setting the pin LOW will tune the coil

//meaning it will respond as a high signal to the reader

//Setting the pin to HIGH will detune coil

//meaning the reader will see it as a low signal

int coil_pin = 9;

void setup( )

{

//Set pin as output

pinMode( coil_pin, OUTPUT );

//Start it as low

digitalWrite( coil_pin, LOW );

}

//Does manchester encoding for signal and sets pins.

//Needs clock and signal to do encoding

void set_pin_manchester( int clock_half, int signal )

{

//manchester encoding is xoring the clock with the signal

int man_encoded = clock_half ^ signal;

//if it's 1, set the pin LOW (this will tune the antenna and the reader sees this as a high signal)

//if it's 0, set the pin to HIGH (this will detune the antenna and the reader sees this as a low signal)

if ( man_encoded == 1 )

{

digitalWrite( coil_pin, LOW );

}

else

{

digitalWrite( coil_pin, HIGH );

}

}

void loop( )

{

//this is the card data we're spoofing. It's basically 10 hex F's

int data_to_spoof[ 64 ] =

{ 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 1, 0, 1, 1, 1, 1, 0, 1, 1, 1, 1, 0, 1,

1, 1, 1, 0, 1, 1, 1, 1, 0, 1, 1, 1, 1, 0, 1, 1, 1, 1, 0, 1, 1, 1, 1, 0, 1,

1, 1, 1, 0, 1, 1, 1, 1, 0, 0, 0, 0, 0, 0 };

for ( int i = 0; i < 64; i++ )

{

set_pin_manchester( 0, data_to_spoof[ i ] );

delayMicroseconds( 256 );

set_pin_manchester( 1, data_to_spoof[ i ] );

delayMicroseconds( 256 );

}

}

RFID Spoofer

Overview

The goal of this project is to learn about RF and RFID.

Thanks to sketchsk3tch for good information.

Being new to electronics development this site was very helpful.

In short we have limited knowledge of electronics and wanted to start learning.

We thought an RFID spoofer would be a fun project.

As we learned more moving forward we decided to turn this into a dev platform for transmitting RFID and not just spoofing.

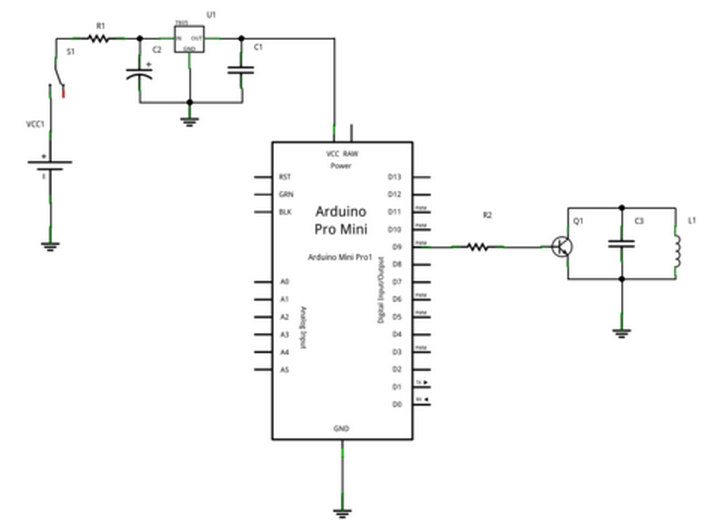

Essentially we took sketchsk3tch's project and made a shield out of it for the Arduino pro mini making it portable.

Parts List

Hardware

Antenna

-

We thought this was a good idea until we did more research. Live and learn.

-

1 x 16”x3/4” PVC pipe

-

2 x 3/4” PVC caps

-

1 x roll of 22 gauge insulated magnet wire

-

1 x male/male headphone cable (I know there is another name for this. I'll update it once I have it)

-

2 x headphone jacks

-

OR —

-

Quick and dirty to test your circuit. Better idea than the above while waiting for your coil craft inductor.

Reference http://www.instructables.com/id/Stupid-Simple-Arduino-LF-RFID-Tag-Spoofer/ -

1 x Toilet Paper Roll

-

1 x roll of 22 gauge insulated magnet wire

-

OR —

-

1 x 4312RV-905XGLB coil from http://www.coilcraft.com

PCB layout - If you want to make your own PCB. Check out our DIY PCB page.

Components

-

Arduino Pro Mini

-

SparkFun FTDI adapter to program the Pro Mini

-

VCC1 9v battery

-

S1 SPDT switch

-

R1 10 ohm resistor

-

R2 10K ohm resistor

-

C1 10uF electrolytic cap

-

C2 10nF film cap

-

C3 220pF ceramic cap

-

U1 LM7805C 5v regulator

-

Q1 NPN 2N3904 transistor

-

L1 CoilCraft 4312RV-905XGLB Induction Coil 9mH

Schematic

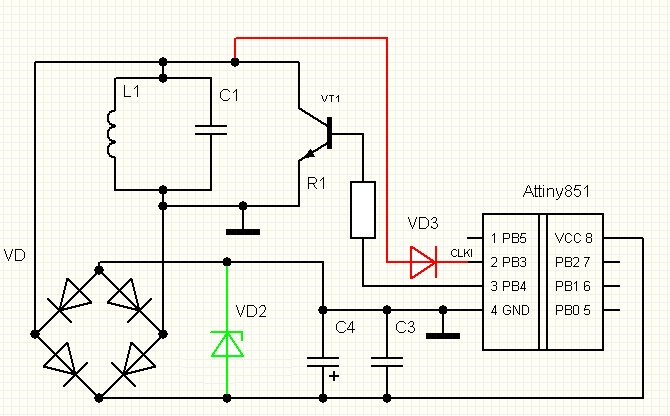

A Card Simulator

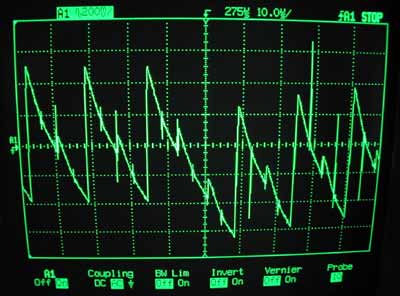

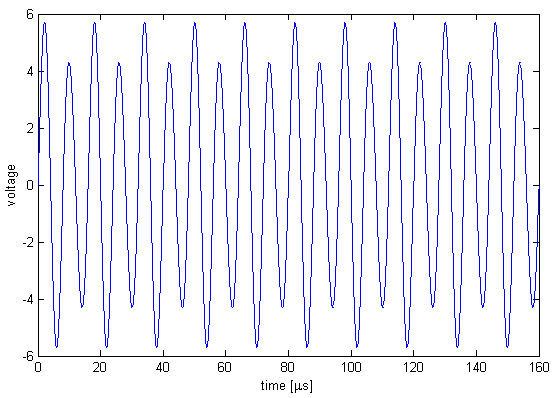

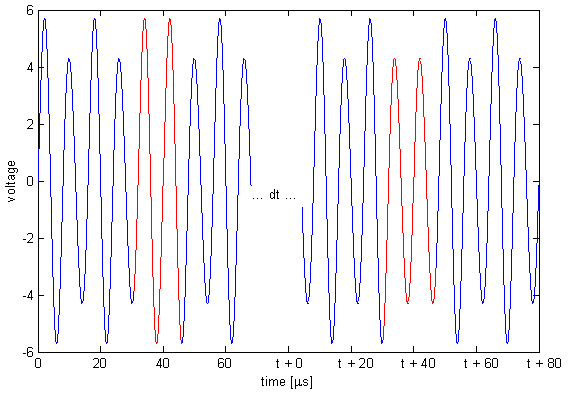

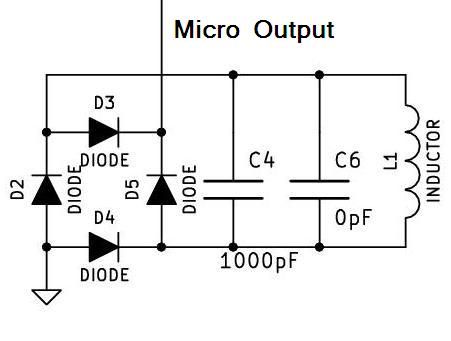

I designed a tag that could produce identical AM when I tested it against my reader.

This was pretty boring. I used a micro and alternately tri-stated or asserted (one low, one high)

two GPIOs connected to one terminal of the tuned coil, with the other antenna terminal grounded.

My tag produced perfect waveforms on my reader.

It did not, however, work with the Motorola readers—the door did not open.

So then I tried a lot of things. Eventually I took a closer look at the output of the peak detector;

it was a 62.5 kHz sawtooth, not 125 kHz.

The card was transmitting PSK, attenuating every other peak, but my peak detector didn't drop fast enough to follow it.

The AM that I saw was a modulation artifact;

I expect (and it's intuitive) that it can be shown that those sorts of amplitude variations

can be obtained by bandpass-filtering a PSK signal.

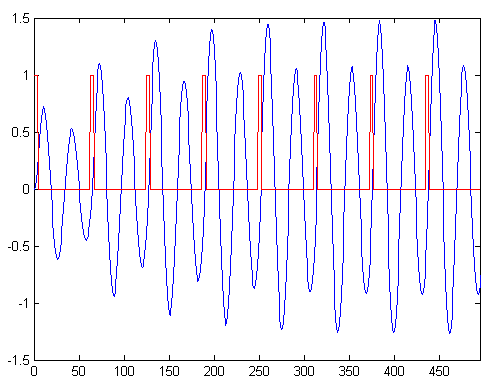

A bit time is 256 μs. The tag's id is periodic over 64 bit times, 16384 μs.

When there is no phase shift, the signal is a 125 kHz sinusoid slightly modulated by a 62.5 kHz sinusoid.

The modulation is greatly exaggerated in the figure.

To indicate a bit transition, the tag inserts a phase shift of π.

There is always an even number of carrier cycles between phase shifts,

so that if the most recent phase shift was achieved by skipping a small-amplitude cycle

then the next phase shift will be achieved by skipping a large-amplitude cycle.

Since a bit time is 256 μs, phase shifts are an integer multiple of 256 μs apart.

Thus, in the above picture, we could have t = 256, 512, 768, ... μs.

A code consists of 64 bit times.

There are no transitions for the last 29 bits for all but one of the cards that I have tested.

Possibly the one card is in a newer format, or possibly it's just weird.

There appears to be some structure within the bits—if I get some of the bits wrong then the reader doesn't even beep,

but if I get others wrong then the reader still beeps but the door doesn't open.

I haven't had any need to figure out which are which though.

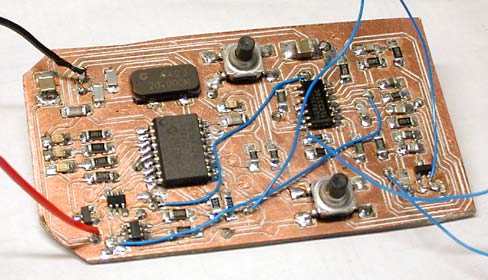

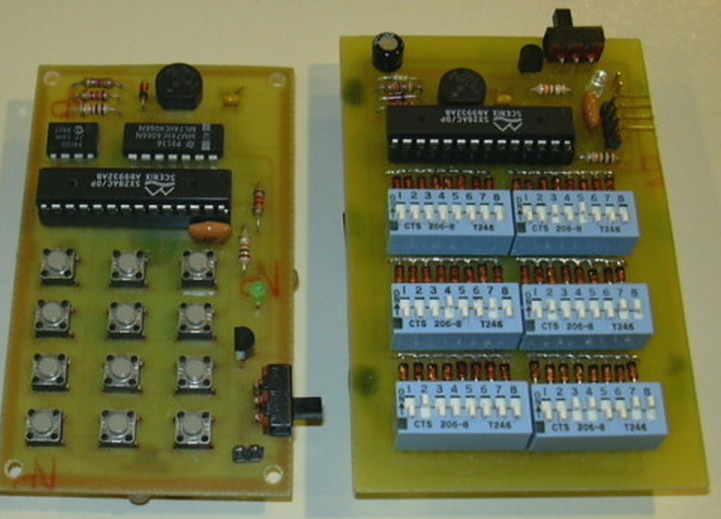

My first tag sort of disintegrated (too many flywires) so I built a new combination reader/tag.

In tag mode I chose to ignore the reader's carrier:

I just blast my own modulated carrier at the reader.

This works perfectly well, and you'd expect it to;

if we're not in phase with the reader's oscillator then we will be in a few hundred milliseconds.

(The beat frequency is ~1 Hz, for a variation of a few ppm, typical for a crystal).

A Toy With Blinking Lights

The hardware to pretend to be a tag is very simple. The hardware to read a tag is not much more complicated; I could do it with a micro, a quad opamp, and a dozen passives. This meant that I could build a combination card reader/simulator in a few square inches of board space. Add a couple of lithium batteries and some nice plastics and I would have a clever and mostly useless pocket-sized toy. Of course I couldn't resist building it.

For a sense of scale, the PIC16F628 (largest IC) and the opamp are both SOICs. There aren't any unreasonably fine-pitch components on this board; the tightest are the SuperSOT FETs (bottom left), with 0.95 mm lead spacing.

The hardware is very similar to the larger reader/simulator described above. I decided not to attempt PSK demodulation; I just detect the modulation artifacts and use the hysteresis, so that I know that if the comparator output has changed state since I looked at it last then there has been a phase shift since then. This sacrifices a bit of sensitivity but my read range is small enough (by design, for reasonable battery life) that this doesn't bother me. This hardware could also be used for AM cards, if I ever came across one.

The PIC can kill power to the detector section with a couple of FET switches. This plus the PIC's sleep mode means that I can do on/off in software without ruining my battery life.

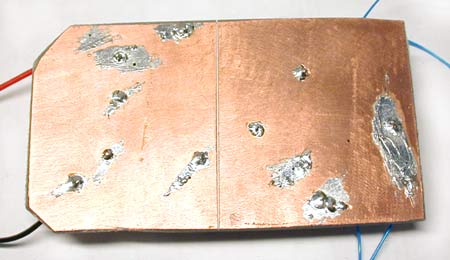

The circuit is again built on a milled PCB, with one signal layer and a ground plane.

The ground plane is split into analog (GND = 0V) and digital (V- = -3V) sections.

It is powered by a pair of CR2032 lithium coin cells. They determine the thickness of the device; the batteries, in a holder, are 0.217" thick.

There are no connectors on the board because I couldn't find any low-profile surface mount connectors that I liked.

Instead there are test points to program the PIC and tune the coil;

I actually built a test/programming fixture (with pogo pins).

This is pretty easy with a CNC machine. P

ower and coil leads are soldered directly to the board.

The blue wires are mostly test points, for debugging only.

The 8 pin header connects to my PIC programmer.

All the plastics were routed from sheet on my milling machine, using an 1/8" carbide straight bit intended for use in wood.

Yes, the workpiece is held to the table by carpet tape; this is much cheaper than a vacuum chuck.

The top and bottom of the case are each 1/16" Lexan (polycarbonate); the core is milled from 6 mm Lexan sheet. The top has drilled holes for the actuators of the two tact switches on the PCB. I paid too much (more than a dollar each!) for the battery holders shown below because they make it very difficult to apply a reverse voltage to the circuit by mis-inserting the cell. The pink foam presses the board into contact with the lid so that the tact switch actuators project.

Both the top and bottom screw into the core with #2 tapping screws. I put a lot of effort into finding a local source for a methylene chloride solvent cement (so that I could weld the bottom on instead of screwing it) but I gave up after many failures. I first tried machine screws but small-diameter machine screws tend to have too many threads per inch to work in plastics. Next time I'd probably look for threaded inserts.

I left the wires long so that I can remove the the board from the plastics without desoldering anything. This is necessary to put it on the programming jig, and it helps when I'm trying to figure out whether I have a circuit-does-the-wrong-thing problem or a 125-kHz-pickup-on-everything problem.

The user interface comprises four LEDs and the two tact switches. The software can currently read a card, store a single id, transmit that id over the air to a reader, blink out that id on the LEDs, and accept a new id on the tact switches. There is also a “sniff” mode, in which the detector is active but the coil is not powered; this allows me to read a card while a legitimate reader is powering it. (The read range of the cards is limited by the tag power requirements, not by reader sensitivity; it goes up substantially when another reader is powering the card.)

Most of the software is pretty straightforward. To transmit the id, I must apply a square wave with, on average, every other cycle missing. I do this entirely in software, flipping a GPIO every 4 μs. I managed to make this work on a 4 MHz device (4 cycles between edges); it's much easier on a 20 MHz device, though. The antenna is resonant around 125 kHz, so that it effectively bandpass filters the pulse train that I generate.

In the figure below, the blue trace is obtained by passing the red trace through a bandpass filter centred at twice the frequency of the pulse train:

For the reader functionality I configure the PWM module to generate the unmodulated square wave so that I can be a bit sloppier with my timing.

I sync on the word by waiting for an edge after a long idle period (though this is of course unnecessary; I only need bit sync). Then I read the word into memory. Then, I read the word ten more times, comparing it against the recorded copy each time; if they all match then I decide that it's right, else I lose sync and try again. This works reasonably well, but if the card is held just barely outside the read range then I will eventually false-sync. This is bad, because there is no other verification. Legitimate readers can false-sync with no major repercussions, since they would just fail to open the door; the user would stand there waiting until the card was read correctly.

Security Implications

I can copy a proximity card at least as easily as I can take an impression of a key. This means that it's not a very good idea to reuse visitor cards without changing the id (and that it doesn't really matter whether you get the physical card back from the guy you just fired).

More insidiously, it's quite practical to read someone's card without removing it from their wallet. A bit of deliberate clumsiness, a reader up my sleeve, and I would have little trouble cloning anyone's card. I could also exploit the fact the distance at which the cards will be powered is less than the distance at which they can be read; if another reader is exciting the card then my reader can read that card from the other side of a wall!

This means that a sniffer concealed somewhere near a legitimate reader could intercept real transactions at a significant distance. This sort of attack is particularly good because the card repeats its id over and over as long as it is in the field, so that I could use signal processing techniques to combine multiple copies of the pattern to further improve my read range. This is easy—if I sample all 64 bits of the id then I don't have to get word-sync, and if I oversample then I don't even have to get bit-sync. Even if I capture the id with a few bit errors it is still useful; I could try the captured id, then every id with a Hamming distance of 1 from the captured id (one bit flipped), then 2, and so on. One or two bit errors would take seconds; three would take minutes.

If I were willing to spend money on a four (or even two) layer board then I could build a sniffer/reader much smaller than anything shown above. If I used black Lexan (or even acrylic) for the case then the device would look less like something that an image-conscious terrorist might carry. This would make it much easier to carry out the attacks outlined above.

All of these attacks can be stopped with a challenge/response scheme. I've seen brochures for cards and readers that do this; I guess it's not just a marketing gimmick.

Hardware Notes

The coil driver consists of an N/P FET pair, with the FETs working as switches.

For my initial reader I connected the drains together, like in a CMOS inverter.

This drove the RLC circuit that was the coil, the tuning cap, and a current-limiting resistor.

This has two flaws.

First, it has a software self-destruct mode;

if the input floats between the positive and negative rails then both FETs will conduct, shorting V+ to V-, and the FETs will get very, very hot.

This caught me because the PIC tri-states all its GPIOs when it's being programmed in system.

There was a bit of a shoot-through problem too; the switching transients got in to everything. Smaller FETs would actually have been better, but I just put some resistance between the drains, because I needed some resistance to limit the current anyways.

My layout seems to be reasonably good. There's hundreds of millivolts of noise on most of the signals around the PIC, but noise on the detector signals is in the tens of millivolts. More bypassing might have cleaned things up further. Not placing the circuit inside the antenna might also have helped....

The detector is rather poor.

When reading (or sniffing) from a large distance, it would be nice to be able to turn down the hysteresis to get some chance at a read. This is not currently possible. It's probably not worth messing with the envelope detector though; it would be better to build a proper PSK detector (by correlating and then integrating the peak detector output in hardware, or with a sharp notch filter to reject the 125 kHz component, allowing me to work only with the sidebands.).

The coin cells probably aren't a very good choice for this application considering the high peak currents—Panasonic's datasheet doesn't even mention what happens if you try to draw more than a milliamp. I don't know what would be better, though; thin batteries are hard to find.

The opamps that I use (TLC2274s) are not low-current. I knew this when I chose them but I assumed that they would only need to be powered when the coil was energized. In sniff mode this is not true; the coil is not driven, and I could even put the PIC to sleep and wake on an edge from the detector. Next time, I guess.

I was careless when I designed the power switching stuff; there were a couple of leakage paths that added almost 60 microamps of off current. I was able to fix this by depopulating a couple of components and faking out the functionality that they used to provide in software. Off current is about 4 μA. The CR2032s can deliver about 200 mAh, for a standby life comparable to the shelf life of the cells.

The presence of metallic objects inside the antenna probably does weird things. Certainly it detunes the coil a bit, and even after I tweaked it back to resonance the voltage on the coil was smaller (indicating that some of my battery life is going to eddy currents in the mounting screws).

I had a few interesting problems relating to 125 kHz pickup from the read coil. The wires from the board to the coil are quite vicious; seriously bad things happen if they rest on the analog traces.

I had a lot of trouble machining the polycarbonate until I got my feeds and speeds right. Too slow of a feed for your speed is very bad; the plastic melts, the cutter loads, friction increases and chip ejection goes to nothing, and you get thermal runaway. Once I figured that out everything went quite easily. Surface finish with an 0.015" finish pass was acceptable as machined almost everywhere. Where it wasn't I used the non-serrated edge of a hacksaw blade to clean it up.

Acrylic makes a nicer case than polycarbonate—it's more rigid and less prone to scratching. An acrylic case probably wouldn't survive a two foot drop onto concrete, though.

Future Plans

The toy described above is nice, but it could be better. I believe that I could sample the peak detector output directly (after AC-coupling it down) and do the demodulation in software. I have a very clever idea that uses the PIC's comparators and voltage reference module to do PSK detection, possibly one so clever that it works only in simulation. This would allow me to lose the opamp entirely. I could drive the coil from a few GPIOs tied together, at the cost of read range. This would get the design down to the micro plus some passives.

I'd also like to get rid of the split supply and run from a single 3 V rail. I think I'd have to do some sort of trick with multiple coils (like a transformer) to get a reasonable input impedance without an unreasonably high Q.

Alternatively, I could build a long range sniffer (better detector, one foot diameter read coil, enough current that it's just on the edge of melting, a motorcycle battery to power the thing...). This wouldn't be nearly as cool as a smaller version of my toy but it would be better for convincing people that the cards are insecure.

October 2003, Waterloo

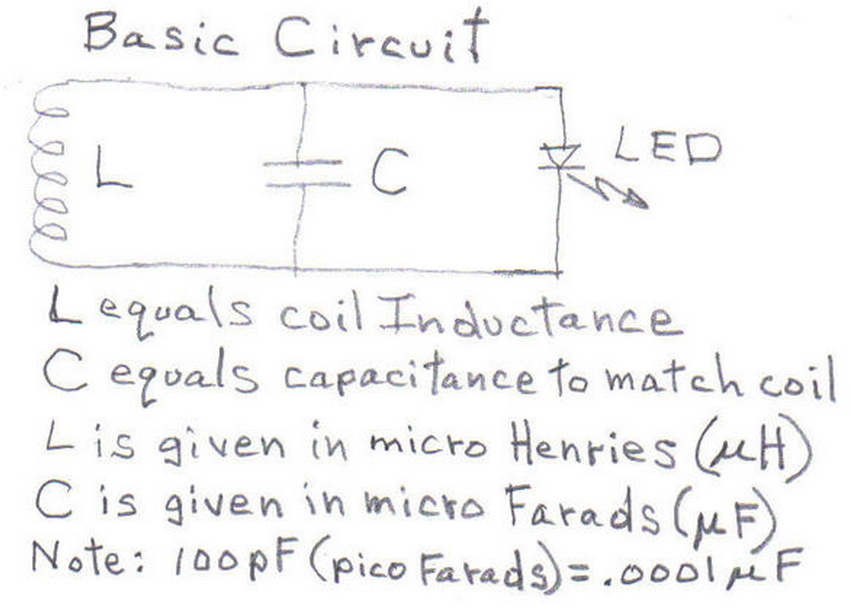

the simplest possible rfid emulator

When looking for a low frequency RFID emulator for security testing purposes, you can find several designs out there.

However, their complexity can make you think twice before building one.

Is necessary that complexity? In some cases you don’t need too much functionality.

Just a simple RFID emulator without fancy capabilities.

How simple can be an emulator? Let’s see.

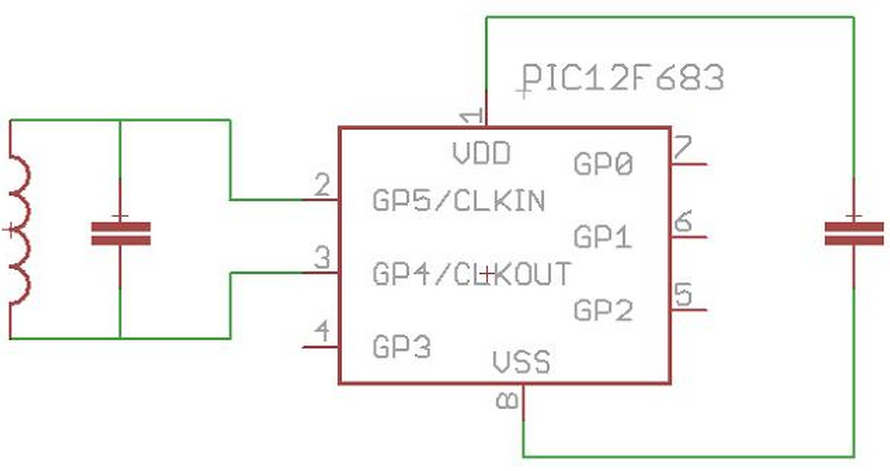

Look this!

HOW IT WORKS?

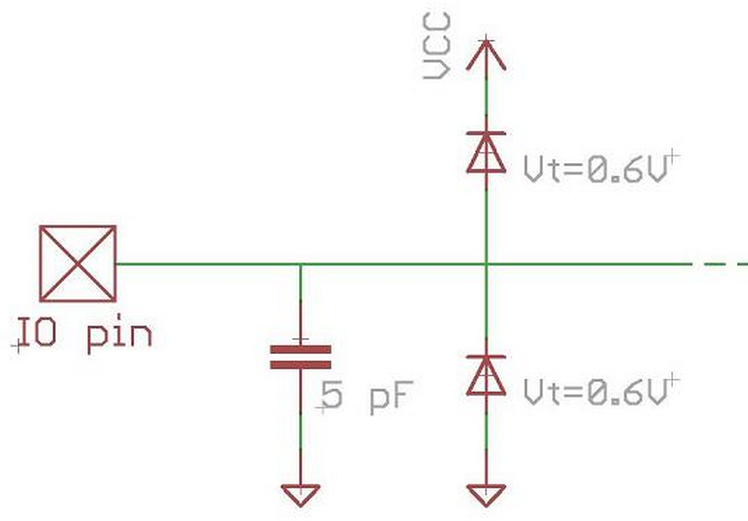

In order to understand how this simple design can works, we have to consider the internal connections of the microcontroller IO ports.

Consulting the datasheet, we can observe that every IO pin has an internal parasite capacitor (around 5pF) and a pair of clamping diodes, as this diagram shows:

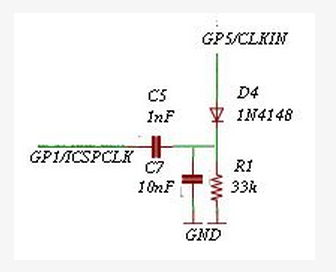

Considering internal capacitance and diodes, the result schematic of this simple emulator is something like:

The parasite capacitor in the IO pins and the external coil form a LC resonant circuit and act as an antenna. This antenna will pick up the carrier generated by the RFID reader.

The recovered carrier is rectified thanks to the bridge formed with the clamping diodes, feeding back the result signal to the power supply of the microcontroller.

Note that the coil (antenna) is connected to the GP5 / CLKIN / OSC1 port. This is important, but we will back to it later.

The other terminal of the coil is connected to the GP4 port. In order to transmit data to the RFID reader, we have to modulate the low frequency carrier by changing the coupling between the reader and tag antennas. We can achieve this by switching the GP4 as input (High-Impedance) or output (connected to GND).

THE FIRMWARE

Some knowledge on PIC assembler is requiered to understand perfectly this section.

Basically, The code for emulating a read-only tag is not more than a bunch of “well-timed” instructions that modify the GP4 state.

This microcontroller (like most of the modern PIC microcontrollers) has an internal oscillator. However, instead of using the internal oscillator, the firmware uses the RFID carrier, present in the GP4 pin, as the system clock.

This way, the firmware is simpler because there is no need to synchronize the data modulation (switching the GP4 pin to GND or High-Impedance) with the RFID carrier. The code execution is already synchronized with the carrier.

The oscillator block has a “relatively” high power consumption, so another reason for not using the internal oscillator is to save energy. And less power means longer reading distance.

As firmware example, you can download this ASM source. It emulates a EM4100 RFID tag, a very common tag.

The EM4100 [datasheet] is a read-only tag with 64 bits of memory and is usually found configured to work at 64 clocks per bit and with Manchester encoding.

The Manchester encoding implies that a ‘1’ encoded bit is transmitted “half-bit” (32 clocks) as ‘0’ and “half-bit” (32 clocks) as a ‘1’.

In this configuration, the ASM code for transmitting a ‘1’ encoded bit is:

BSF TRISIO, GP4 ; GP4 as input (High-Impedance). Transmit a '0'. NOP NOP NOP NOP NOP NOP NOP

BCF TRISIO, GP4 ; GP4 as output (GND). Transmit a '1' NOP NOP NOP NOP NOP NOP NOP

Note that between the execution of the BSF and the BCF instructions there are exactly 8 instruction cycles. Considering that the PIC architecture uses 4 system clocks for executing one instruction, it means that pass exactly 32 carrier clocks between the two instructions.

A ‘0’ encoded bit is transmitted in a similar way.

The schematic with the cited improvements: