PCB Genesis 外形加内角孔实现方法

在PCB工程制作CAM时,经常会遇到外形拐角处直角的,而客户对内角是要求,比如最大内角要求R0.5mm或者不接受内角,

但成型方式为铣方式,又不是啤板成型,那怎么处理才可以达到要求效果呢,在这里介绍2种方法。

一.采用大小锣刀分2次锣外形

由于采用2次锣,此效率较低,目前PCB行业基本已放弃此方法了处理内角了,

要知道我们PCB行业是非常很重视效率,为了提高效率,PCB行业普遍采用第2种方法(详见方法2)

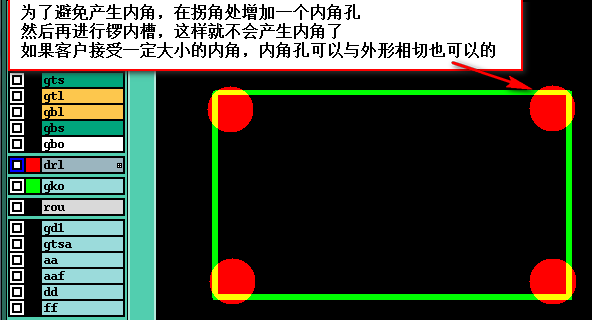

二.在外形拐角处加----内角孔

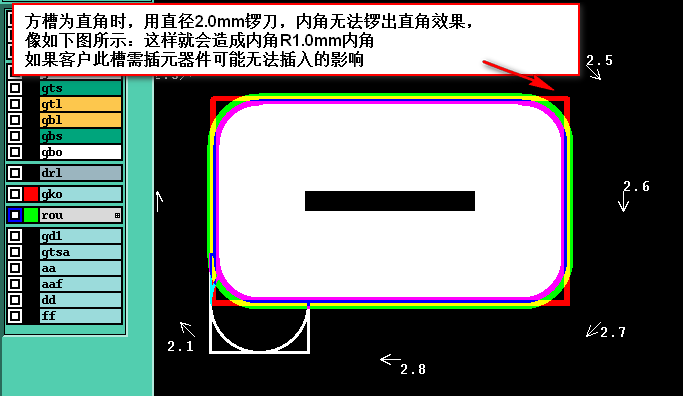

方槽为直角时,用直径2.0mm锣刀,内角无法锣出直角效果,

像如下图所示:这样就会造成内角R1.0mm内角

如果客户此槽需插元器件可能无法插入的影响

如下图这样加内角孔后,比第一种方法效率要高多了,也达到了同样处理内角的效果

三.实现原理图解:

四.代码实现:

如下代码是:线与线求相切圆, (弧与线,弧与弧 求相切圆的原理是相似的,可以在此基础上扩展)

/// <summary> /// 线段与线段倒圆角 /// </summary> /// <param name="l1"></param> /// <param name="l2"></param> /// <param name="tolerance"></param> /// <returns></returns> public gL_di l2l_Round(ref gL l1, ref gL l2, double Radius, double tolerance = 0.5) { gL_di gldi = new gL_di(); int isIntersectType = 0; gPoint pc = l2l_Intersect(l1, l2, ref isIntersectType); if (isIntersectType == 0) //平行无交点 平行线方位角相同 接近平行线 相差接近 { return gldi; } else { double l1pspc = p2p_di(pc, l1.ps); double l1pepc = p2p_di(pc, l1.pe); double l2pspc = p2p_di(pc, l2.ps); double l2pepc = p2p_di(pc, l2.pe); gPoint p1, p2, p11, p22; double p1pc, p2pc; Ptype p1Type, p2Type; if (l1pspc > l1pepc) { p1 = l1.pe; p11 = l1.ps; p1pc = l1pepc; p1Type = Ptype.pe; } else { p1 = l1.ps; p11 = l1.pe; p1pc = l1pspc; p1Type = Ptype.ps; } if (l2pspc > l2pepc) { p2 = l2.pe; p22 = l2.ps; p2pc = l2pepc; p2Type = Ptype.pe; } else { p2 = l2.ps; p22 = l2.pe; p2pc = l2pspc; p2Type = Ptype.ps; } gldi = new gL_di(p1, p1Type, p2, p2Type, pc); //交点与2条线端点距离判断 确认两条线是否接合 ---另一个参数 两条相接近平行且两条线接近需加以修复,延长非常长,超公差,但也需修复 if (p1pc > tolerance || p2pc > tolerance) return gldi; //倒角线段长小于圆弧半径 if ((p1Type == Ptype.ps && l1pepc < Radius) || (p1Type == Ptype.pe && l1pspc < Radius)) return gldi; if ((p2Type == Ptype.ps && l2pepc < Radius) || (p2Type == Ptype.pe && l2pspc < Radius)) return gldi; double center_dirdction = 0; bool islg180deg = true; double pcAng = a_Angle(p11, pc, p22, false, ref center_dirdction, ref islg180deg);//交点圆心角 if (Math.Abs(180 - pcAng) < 0.01) //夹角接近180度 返回 return gldi; double pcSinVal = Radius / (Math.Sin(pcAng * 0.5 * Math.PI / 180)); //交点增量 double pcTanVal = Radius / (Math.Tan(pcAng * 0.5 * Math.PI / 180)); //交点Tan增量 gA ga = new gA(); ga.pc = p_val_ang(pc, pcSinVal, center_dirdction); ga.ps = p_val_ang(pc, pcTanVal, center_dirdction - pcAng * 0.5); ga.pe = p_val_ang(pc, pcTanVal, center_dirdction + pcAng * 0.5); ga.width = 500; ga.symbols = ""; gldi.a = ga; gldi.State = 1; if (p1Type == Ptype.pe) { l1.pe = islg180deg ? ga.pe : ga.ps; } else { l1.ps = islg180deg ? ga.pe : ga.ps; } if (p2Type == Ptype.pe) { l2.pe = islg180deg ? ga.ps : ga.pe; } else { l2.ps = islg180deg ? ga.ps : ga.pe; } } return gldi; }

返回Mode类

/// <summary> /// Line 数据类型 /// </summary> public struct gL_di { public gL_di(gPoint p1_, Ptype p1_Ptype_, gPoint p2_, Ptype p2_Ptype_, gPoint pc_ = new gPoint()) { this.p1 = p1_; this.p2 = p2_; this.p1_Ptype = p1_Ptype_; this.p2_Ptype = p2_Ptype_; this.pc = pc_; this.State = 0; this.a = new gA(); } /// <summary> /// 状态 0失败 1成功 /// </summary> public int State { get; set; } /// <summary> /// P1端点 /// </summary> public gPoint p1 { get; set; } /// <summary> /// P2端点 /// </summary> public gPoint p2 { get; set; } /// <summary> /// 原线段P1端点类型 /// </summary> public Ptype p1_Ptype { get; set; } /// <summary> /// 原线段P2端点类型 /// </summary> public Ptype p2_Ptype { get; set; } /// <summary> /// 倒角后生成的数据 /// </summary> public gA a { get; set; } /// <summary> /// PC端点(交点) /// </summary> public gPoint pc { get; set; } public double p1p2_di { get { return p2p_di(this.p1, this.p2); } } public double p1pc_di { get { return p2p_di(this.p1, this.pc); } } public double p2pc_di { get { return p2p_di(this.p2, this.pc); } } /// <summary> /// 返回两点之间欧氏距离 /// </summary> /// <param name="p1"></param> /// <param name="p2"></param> /// <returns></returns> public static double p2p_di(gPoint p1, gPoint p2) { return Math.Sqrt((p1.x - p2.x) * (p1.x - p2.x) + (p1.y - p2.y) * (p1.y - p2.y)); } }

五.框选加内角孔实现效果

六.整板加内角孔实现效果

作者:pcbren 微信号:yadnfku QQ号: 254566449

博客地址:https://www.cnblogs.com/pcbren/

声明:本博客原创文字只代表本人工作中在某一时间内总结的观点或结论,与本人所在单位没有直接利益关系。非商业,未授权,贴子请以现状保留,转载时必须保留此段声明,且在文章页面明显位置给出原文连接。

如果大家感觉我的博文对大家有帮助,请推荐支持一把。

浙公网安备 33010602011771号

浙公网安备 33010602011771号