Multiplex Drive and Bias of LCD Technology

![]() LCD MULTIPLEX RATIO

LCD MULTIPLEX RATIO

The configuration for Liquid Crystal Display Multiplex Drive technique differs from a Static Drive technique is that it uses more than a single "backplane" or segment common. With this configuration, each segment control line can be connected to as many segments as there are backplanes, providing that each of the segments that it is connected to are tied to a separate backplanes. This method "Multiplexes" each of the segment control lines and minimizes the number of interconnects. This is the method used with complex displays that have limited interconnection surface area or available drive circuits. This reduction in the number of external connections enhances device reliability and increases the potential display density. The liability of a higher multiplex rate will effect display quality, operational temperature range, and the increased complexity of drive circuitry (or perhaps microprocessor software) may necessary for their operation.

The method of drive for multiplexed displays is essentially a time division multiplex with the number of time divisions equal to twice the number of common planes used in a given format. As is the case with conventional LCDs, in order to prevent irreversible electrochemical action from destroying the display, the voltage at all segment locations must be caused to reverse polarity periodically so that zero net DC voltage is applied. This is the reason for the doubling in time divisions: Each common plane must be alternately driven with a voltage pulse of opposite polarity.

As is the case with non multiplexed displays, the drive frequency should be chosen to be above the flicker-fusion rate, i.e. >30 Hz. Since increasing the drive frequency significantly above this value increases current demand by the CMOS drive electronics, and to prevent problems due to the finite conductivity of the display segment and common electrodes, an upper drive frequency limit of 60-90 Hz is recommended.

![]() LCD BIAS

LCD BIAS

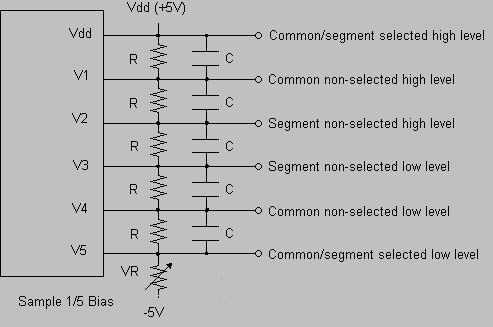

The control signals that drive an LCD are AC in nature. The basic configuration of how to generate a waveform to control an LCD are covered in the sections "LCD Multiplex Ratio (above)" and "LCD Static Drive Technology". But to control LCDs with a larger multiplex ratio, we need to provide the waveform generator with multiple bias voltage level points. The resulting waveform sent to the LCD segment/dot control lines and backplane commons will contain a stair-stepped waveform that will maintain specific ac voltages across any given segment/dot to keep it in it's "on" or "off" state (or in a grayscale module, states between those two points). The LCD Bias number (example: 1/5 bias) will indicate how many voltage reference points are created to drive a specific LCD. The table below shows the relationship between the number of driving bias voltages and the display multiplex ratios typically used:

| Mux Ratio |

Static | 1/2 | 1/3 | 1/4 | 1/7 | 1/8 | 1/11 | 1/12 | 1/14 | 1/16 | 1/24 | 1/32 | 1/64 |

| Biases | 2 | 3 1/2 Bias |

4 1/3 Bias |

5 1/4 Bias |

6 1/5 Bias |

||||||||

The necessary bias voltages are usually generated by the use of a resistor dividing network, and example of which is shown below using Vdd at 5 volts, and the number of resistors in the ladder determined using the table above.

The values of the resistors is determined by the required voltage reference points and possible waveform distortion. Because an LCD is a capacitive load, the values should be decreased to decrease distortion, or with larger displays, buffering the voltage reference points with op-amps.

Multiplexing and Bias of LCD Technology (pacificdisplay.com)

浙公网安备 33010602011771号

浙公网安备 33010602011771号