[CAN波形分析] 一次CAN波形分析之旅

Prepare

CAN通信协议使用了有一段时间了,但都是基于软件层面的使用,对于其波形不是很了解,正好这段时间比较闲,是时候补补硬知识。

开始之前,先介绍一下设备:

- 咸鱼淘来的古董级别示波器GDS-2202。200MHz,数据记录长度是12500个点(每个点40ns,总记录长度是500us)

- EK-LM4F120XL开发板。也就是现在的EK-TM4C123GXL,板载MCU是TM4C1233H6PM,对应原来的老型号LM4F120H5QR

- CAN收发器,TJA1050模块

Ongoing

软件准备

用CCS9.0导入TI提供的CAN驱动库,每隔1秒钟发送一个CAN信息:

- 波特率:500 kb/s

- ID(Normal): 0x220

- 信息长度 :4 bytes

- 数据:0x12, 0x34, 0x56, 0x78

1 int main(void) 2 { 3 tCANMsgObject sCANMessage; 4 unsigned char ucMsgData[4]; 5 6 // 7 // Set the clocking to run directly from the external crystal/oscillator. 8 // TODO: The SYSCTL_XTAL_ value must be changed to match the value of the 9 // crystal on your board. 10 // 11 SysCtlClockSet(SYSCTL_SYSDIV_2_5 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN | 12 SYSCTL_XTAL_16MHZ); 13 14 // 15 // Set up the serial console to use for displaying messages. This is 16 // just for this example program and is not needed for CAN operation. 17 // 18 InitConsole(); 19 20 // 21 // For this example CAN0 is used with RX and TX pins on port D0 and D1. 22 // The actual port and pins used may be different on your part, consult 23 // the data sheet for more information. 24 // GPIO port D needs to be enabled so these pins can be used. 25 // TODO: change this to whichever GPIO port you are using 26 // 27 SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE); 28 29 // 30 // Configure the GPIO pin muxing to select CAN0 functions for these pins. 31 // This step selects which alternate function is available for these pins. 32 // This is necessary if your part supports GPIO pin function muxing. 33 // Consult the data sheet to see which functions are allocated per pin. 34 // TODO: change this to select the port/pin you are using 35 // 36 GPIOPinConfigure(GPIO_PE4_CAN0RX); 37 GPIOPinConfigure(GPIO_PE5_CAN0TX); 38 39 // 40 // Enable the alternate function on the GPIO pins. The above step selects 41 // which alternate function is available. This step actually enables the 42 // alternate function instead of GPIO for these pins. 43 // TODO: change this to match the port/pin you are using 44 // 45 GPIOPinTypeCAN(GPIO_PORTE_BASE, GPIO_PIN_4 | GPIO_PIN_5); 46 47 // 48 // The GPIO port and pins have been set up for CAN. The CAN peripheral 49 // must be enabled. 50 // 51 SysCtlPeripheralEnable(SYSCTL_PERIPH_CAN0); 52 53 // 54 // Initialize the CAN controller 55 // 56 CANInit(CAN0_BASE); 57 58 // 59 // Set up the bit rate for the CAN bus. This function sets up the CAN 60 // bus timing for a nominal configuration. You can achieve more control 61 // over the CAN bus timing by using the function CANBitTimingSet() instead 62 // of this one, if needed. 63 // In this example, the CAN bus is set to 500 kHz. In the function below, 64 // the call to SysCtlClockGet() is used to determine the clock rate that 65 // is used for clocking the CAN peripheral. This can be replaced with a 66 // fixed value if you know the value of the system clock, saving the extra 67 // function call. For some parts, the CAN peripheral is clocked by a fixed 68 // 8 MHz regardless of the system clock in which case the call to 69 // SysCtlClockGet() should be replaced with 8000000. Consult the data 70 // sheet for more information about CAN peripheral clocking. 71 // 72 73 sysclk = SysCtlClockGet(); 74 CANBitRateSet(CAN0_BASE, sysclk, 500000); 75 76 // 77 // Enable interrupts on the CAN peripheral. This example uses static 78 // allocation of interrupt handlers which means the name of the handler 79 // is in the vector table of startup code. If you want to use dynamic 80 // allocation of the vector table, then you must also call CANIntRegister() 81 // here. 82 // 83 // CANIntRegister(CAN0_BASE, CANIntHandler); // if using dynamic vectors 84 // 85 CANIntEnable(CAN0_BASE, CAN_INT_MASTER | CAN_INT_ERROR | CAN_INT_STATUS); 86 87 CANRetrySet(CAN0_BASE, false); 88 // 89 // Enable the CAN interrupt on the processor (NVIC). 90 // 91 IntEnable(INT_CAN0); 92 93 // 94 // Enable the CAN for operation. 95 // 96 CANEnable(CAN0_BASE); 97 98 // 99 // Initialize the message object that will be used for sending CAN 100 // messages. The message will be 4 bytes that will contain an incrementing 101 // value. Initially it will be set to 0. 102 // 103 *(unsigned long *)ucMsgData = 0; 104 sCANMessage.ulMsgID = 0x220; // CAN message ID 105 sCANMessage.ulMsgIDMask = 0; // no mask needed for TX 106 sCANMessage.ulFlags = MSG_OBJ_TX_INT_ENABLE; // enable interrupt on TX 107 sCANMessage.ulMsgLen = sizeof(ucMsgData); // size of message is 4 108 sCANMessage.pucMsgData = ucMsgData; // ptr to message content 109 110 ucMsgData[0] = 0x12; 111 ucMsgData[1] = 0x34; 112 ucMsgData[2] = 0x56; 113 ucMsgData[3] = 0x78; 114 // 115 // Enter loop to send messages. A new message will be sent once per 116 // second. The 4 bytes of message content will be treated as an unsigned 117 // long and incremented by one each time. 118 // 119 for(;;) 120 { 121 // 122 // Print a message to the console showing the message count and the 123 // contents of the message being sent. 124 // 125 UARTprintf("Sending msg: 0x%02X %02X %02X %02X", 126 ucMsgData[0], ucMsgData[1], ucMsgData[2], ucMsgData[3]); 127 128 // 129 // Send the CAN message using object number 1 (not the same thing as 130 // CAN ID, which is also 1 in this example). This function will cause 131 // the message to be transmitted right away. 132 // 133 CANMessageSet(CAN0_BASE, 1, &sCANMessage, MSG_OBJ_TYPE_TX); 134 135 // 136 // Now wait 1 second before continuing 137 // 138 SimpleDelay(); 139 140 // 141 // Check the error flag to see if errors occurred 142 // 143 if(g_bErrFlag) 144 { 145 UARTprintf(" error - cable connected?\n"); 146 } 147 else 148 { 149 // 150 // If no errors then print the count of message sent 151 // 152 UARTprintf(" total count = %u\n", g_ulMsgCount); 153 } 154 155 // 156 // Increment the value in the message data. 157 // 158 //(*(unsigned long *)ucMsgData)++; 159 } 160 161 // 162 // Return no errors 163 // 164 return(0); 165 }

编译,通过板载调试器下载代码,复位运行代码。

硬件准备

示波器探头CH1连接TJA1050的CANH引脚,探头CH2连接CANL引脚,地跟开发板的GND连接,使用边沿触发模式捕获波形:

分析

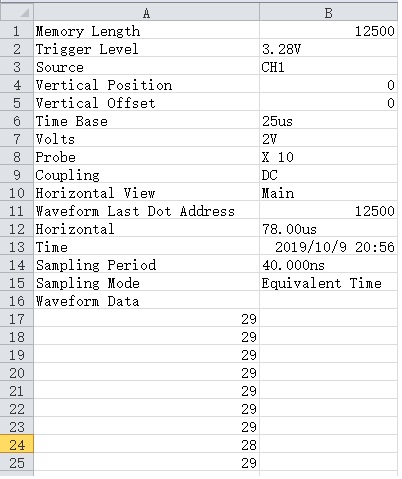

为了方便分析,将波形保存成CSV格式。该CSV文件记录了波形信息和数据,从第17行开始,就是波形的数据,如下图:

使用Matplotlib导入CSV,绘制折线图,代码如下:

1 import csv 2 import matplotlib 3 import matplotlib.pyplot as plt 4 import matplotlib.collections as collections 5 from matplotlib.ticker import MultipleLocator 6 import numpy as np 7 import pandas as pd 8 9 ax = plt.subplot() 10 #将x主刻度标签设置为125的倍数 11 xmajorLocator = MultipleLocator(125) 12 ax.xaxis.set_major_locator(xmajorLocator) 13 #y轴数据 14 raw_canh = pd.read_csv("canh.csv") 15 raw_canl = pd.read_csv("canl.csv") 16 #x轴数据 17 t = np.arange(130, 12000, 1) 18 ax.plot(t, raw_canh[130:12000], raw_canl[130:12000]) 19 ax.xaxis.grid(True) 20 21 plt.show()

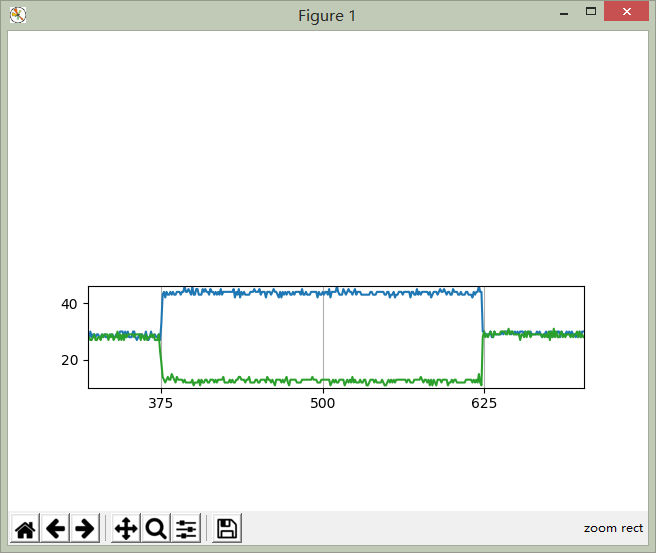

运行,效果如下,

局部放大波形图,

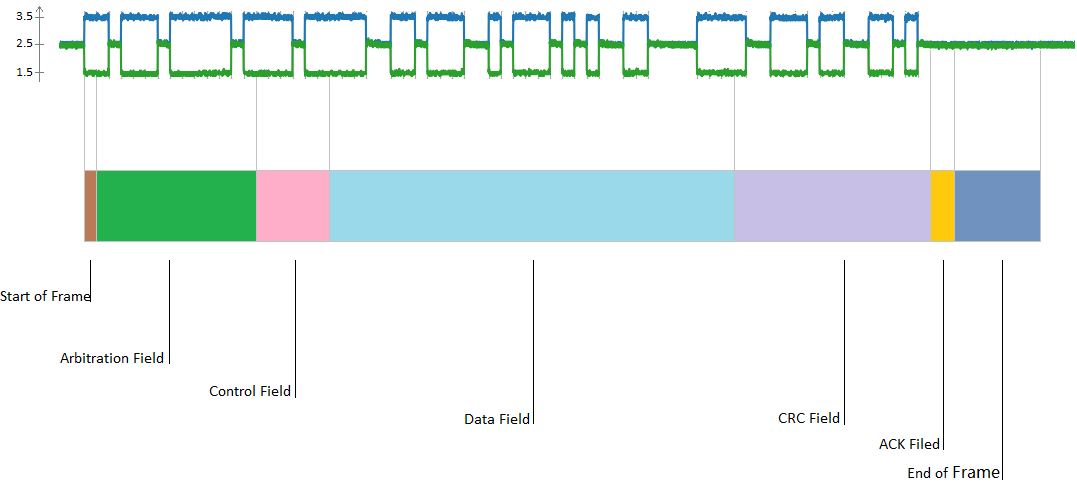

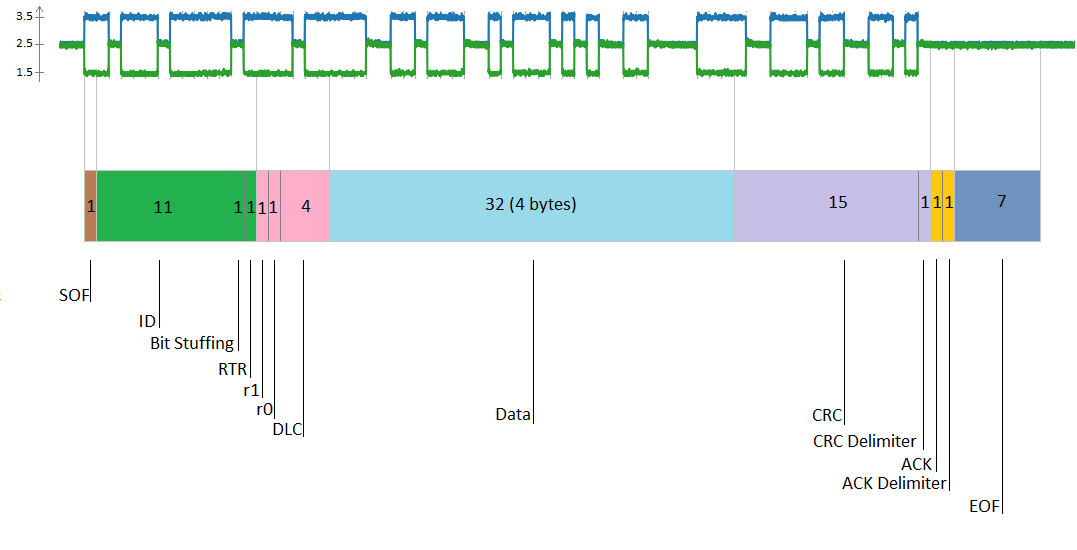

接下来的工作就是PS了,参照CAN2.0B的Spec,找到每一位的定义。首先是整个数据帧(Data Frame)的定义,

进一步细化每个字段(Field):

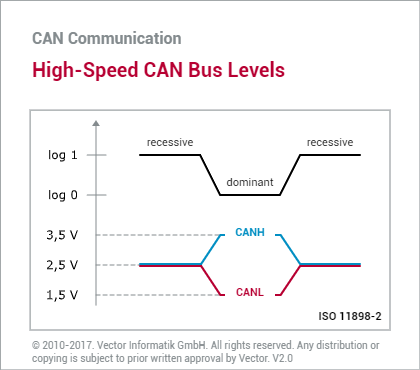

将差分信号转换为实际的二进制值,十六进制值。这里需要补充一点知识,CAN信号电压与实际逻辑的关系,很好记忆,波形像口张开的(O),表示逻辑0(显示);另外一种则表示逻辑1(隐性)。如下图:

根据上面的信息,我们可以进一步得到以下数据,

如果你很细心的看上面图,就会发现一个问题,有些十六进制为什么是有9位?因为有一位是填充位(Bit Stuffing),CAN2.0的协议规定,连续5个显性/隐性电平后,要填充一位隐性/显性电平。如上图中的仲裁字段(Arbitration Field),连续5个'0'后,填充一个'1'。

Post

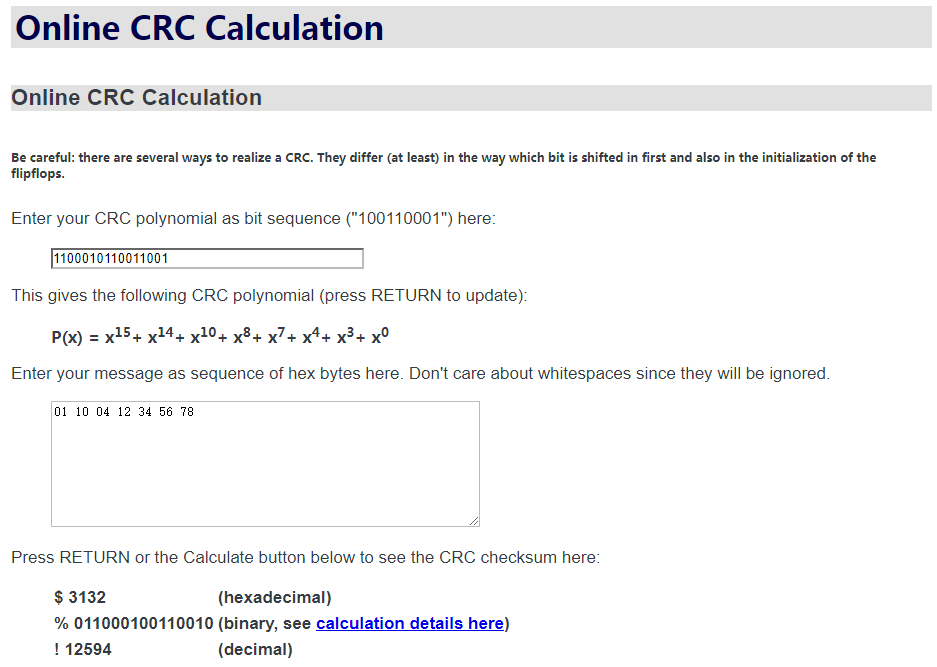

分析到这里接近尾声了,还有一个疑问,这个CRC校验是怎么算出来的呢?从CAN2.0的Spec了解到,CRC的计算的值从SOF开始,到数据字段(Data Field),多项式:

P(x) = x15+ x14+ x10+ x8+ x7+ x4+ x3+ 1

通过在线CRC计算网站,输入我们的数据,计算CRC的值:

如我们所料,计算的CRC值是正确的!

-----------------------------------------------------------------------------------END

[参考资料]

【推荐】国内首个AI IDE,深度理解中文开发场景,立即下载体验Trae

【推荐】编程新体验,更懂你的AI,立即体验豆包MarsCode编程助手

【推荐】抖音旗下AI助手豆包,你的智能百科全书,全免费不限次数

【推荐】轻量又高性能的 SSH 工具 IShell:AI 加持,快人一步

· 开发者必知的日志记录最佳实践

· SQL Server 2025 AI相关能力初探

· Linux系列:如何用 C#调用 C方法造成内存泄露

· AI与.NET技术实操系列(二):开始使用ML.NET

· 记一次.NET内存居高不下排查解决与启示

· 阿里最新开源QwQ-32B,效果媲美deepseek-r1满血版,部署成本又又又降低了!

· 开源Multi-agent AI智能体框架aevatar.ai,欢迎大家贡献代码

· Manus重磅发布:全球首款通用AI代理技术深度解析与实战指南

· 被坑几百块钱后,我竟然真的恢复了删除的微信聊天记录!

· AI技术革命,工作效率10个最佳AI工具