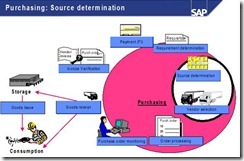

Source Determination

Source Determination

Use

The source determination facility helps you to find the most suitable source for a certain requirement from the large volume of data that is available, i.e. it suggests a suitable outline agreement or vendor for ordering purposes.

Integration

The following objects represent the basic data upon which the source determination process for requisitions and purchase orders depends:

· Outline agreement

· Quota arrangement

· Source list

· Info record

· Plant

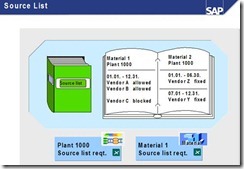

一、Source List

Use

The source list is used in the administration of sources of supply.

It specifies the allowed (and disallowed) sources of a material for a certain plant within a predefined period. Each source is defined by means of a source list record.

供货来源有供货商(SAP中表现为信息记录和框架协议)和内部工厂(用于stock transfer)两种。我们这里讲的source list主要是采购中,供货商的表现形式。在创建PR的时候,如果将source determination选项勾选(如图),则系统会搜索所有货源,如果没有预先设定的首选项,则可以将列出清单。可以通过价格模拟和供应商评估来决定供货商。

另外,可以在用户参数中配置EFB来禁止用户手动指定供货商。

1. Source determination将发生在如下业务:

1.1. MRP运行 MD01/MD02/MD03

1.2. 创建PR ME51N

1.3. PR分配 ME56

1.4. PR分配和处理 ME57

1.5. 创建PO,vendor未知 ME25

1.6. 计划订单转化为PR MD14/MD15

2. Source List的功能

2.1. 定义一个vendor为固定的供货商(除了MRP运行) 同类型的(信息记录或框架协议)固定vendor只能有一个,如果不同类型的都有一个固定vendor,则框架协议的具有的优先级较高

2.2. 定义从某个内部工厂采购。只有PR的明细类型为U(stock transfer 库存转储)时起作用

2.3. Block某个vendor 如图,如果没有设置vendor而只是输入有效期间和block,则表示这段时期内,此物料在相关工厂不能外购

2.4. MRP相关 如果设置为1,则MRP运行时考虑此项作为货源,如果此项为SA,设置为2,可产生SA的schedule line前面提到过,如果一个物料没有维护源清单则禁止采购,可以如图在物料主数据中设置和后台配置(Purchasing->Source List)某个工厂的物料采购都需要源清单

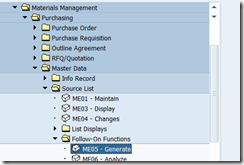

我们可以通过ME06(Purchasing->Master Data->Source List->Follow-On Functions)来分析某个工厂下哪些物料还没有源清单

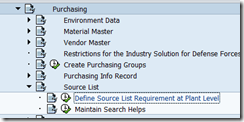

3. Define requirement of Source list

3.1 by Material

3.2. by Plant

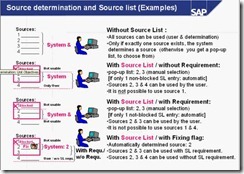

4. Source List 对Source Determination的影响

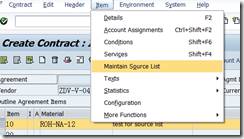

4.1 为了好理解,这里手动维护Source list

Maintain SL manually --- ME01

4.2对应的设置主要是影响PR中Source Supply

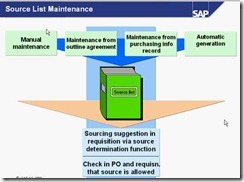

5. Source List的几种维护方式

5.1 Maintain SL manually --- ME01

5.2 Set SL from outline agreement

5.2.1. by contract --- ME31K

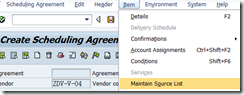

5.2.2 by SA --- ME31L

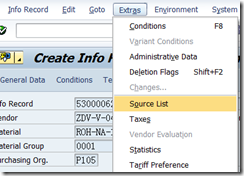

5.2.3 Maintenance from p-info

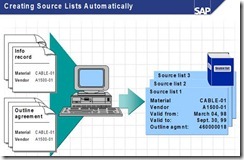

5.2.4 Automatic Generation of the Source List --- ME05

6. MRP自动生成计划行

6.1 source list 放“协议”号码和Item

6.2物料需求计划选2

6.3 交货计划表要设定

MD61

二、Quota Arrangement

Use

The quota arrangement is an instrument used in sourcing administration.

A quota arrangement divides the total requirement of a material over a period among certain sources of supply by assigning a quota to each source.

The quota specifies which portion of the total requirement should be procured from a given source.

If a quota arrangement exists for a material, it is taken into account in the source determination process.

A quota arrangement is specified for a certain period. A quota arrangement item is created for each source within the period.

源文档 <http://help.sap.com/erp2005_ehp_05/helpdata/EN/75/ee115f55c811d189900000e8322d00/content.htm>

1. Quota Type:

Lot Size--Splitting Quota:用来控制是否分割Quota,一个lot是否可以按照Quota拆分,由Splitting Quota标识决定

2. Quota Rating:

Rate越低,表示Vendor的达成率越高,优先予以分配。

Quota Rating = Quota Alloc Qty/Quota = (Allocted Qty + Quota Base Qty) / Quota

(配额达成率 = (累计已经分配数量+新材料调整基数)/ 分配额

3. Vendor Allocating Rating

Allocate Percent = Quota/∑Quota

(某Vendor分配比例 = 某供应商配额/总配额)

4. Quota的方式

4.1 Quota Rating -- non-splitting Quota

4.2 Vendor Allocating Rating -- Requirement splitting Quota

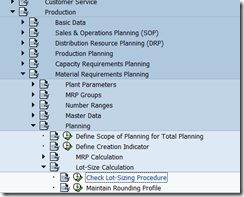

SAP Quota优先采用Quota Rating的分配方式(即不分割),如要用Splitting的方式需要在Mat. Master Data中的MRP1 View设定Splitting方式(daily/weekly/monthly lot size都要设定)。

5. Quota MMR Setting

5.1 当使用Quota的功能时,必须在Purchasing View中设定Quota Usage为4.

5.2 如需要使用Splitting方式时,须在MRP 1 View中设定Lot Size为已选中Splitting Quota的那些Lot Size

6. Quota Parameters --- MEQ1

6.1 Procurement Type

设定quota物料的自制、外购

6.2 Source

定义向那个Vendor或者向那个Plant购买

6.3 Alloc. Qty

针对此Quota,在系统中已经分配的数量

6.4 Max Qty

分配给某Vendor 的最大数量,达到此数量后再不会分配给此Vendor

6.5 Quota Based

当在做Quota一段时间后,如果有新Vendor加入,因之前的供应商都已经存在Allocation,则此新Vendor的Rate会很多,短时间内会出现一直分配给此Vendor,所以可以设定此初始基数以防止此种情况发生

6.6 Max Lot Size

达到Max Lot Size时系统会自动拆分成两张PR(eg. 某Vendor Max Lot Size为20,按分配原则需给它分配30的量,则系统会开出20pc和10pc两张PR)

6.7 Mix lot Size

6.8 R. Profile -- Round Profile

即最小包装量

6.9 One Time

在同一次需求中只能给此Vendor一次需求

6.10 Max Rel.Qty

在某个区间中的最大分配数

三、Others

1. ME01 - Create Source List

2. ME05 - Generate