平带和V形带的区别

What is the difference between V-belts and flat belts?

1、平带 flat-belt

In comparison to V-belts, flat belts require significantly higher pretensioning in order to transmit a certain torque without slippage. This especially applies to large transmission ratios and thereby low angles of contact. Tension pulleys with defined contact pressure are recommended in cases of this kind to reduce the transverse force

Flat belts are not advisable for high outputs at high speeds.

与 V 形皮带相比,平带需要更高的预紧力才能在不打滑的情况下传输一定扭矩。

这尤其适用于较大的传输比,从而降低接触角度。在此类情况下,建议使用具有定义接触压力的张力滑轮,以减少横向力

对于高速下的高输出,不建议使用扁平皮带。

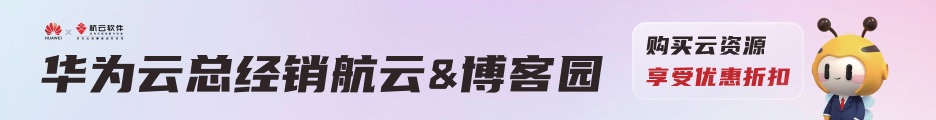

Angle of contact increased by tension pulley for reducing transverse force.

2、齿形带 V-belt

V-belts are characterized by their trapezium shaped (v-shaped) cross-section. They consist of a tensioning section of multiple layers of endlessly wound polyester fiber cord threads, the core which is made of a high-quality rubber mixture and the enclosure which is made of rubberized cotton or synthetic fabric. Depending on the intended use, different designs are used.

V 形带的特点是其梯形(V 形)横截面。它们包括多层无边缠绕聚酯纤维线线的张力部分,核心由高品质的橡胶混合物制成,外壳由橡胶棉或合成织物制成。根据预期用途,使用不同的设计。

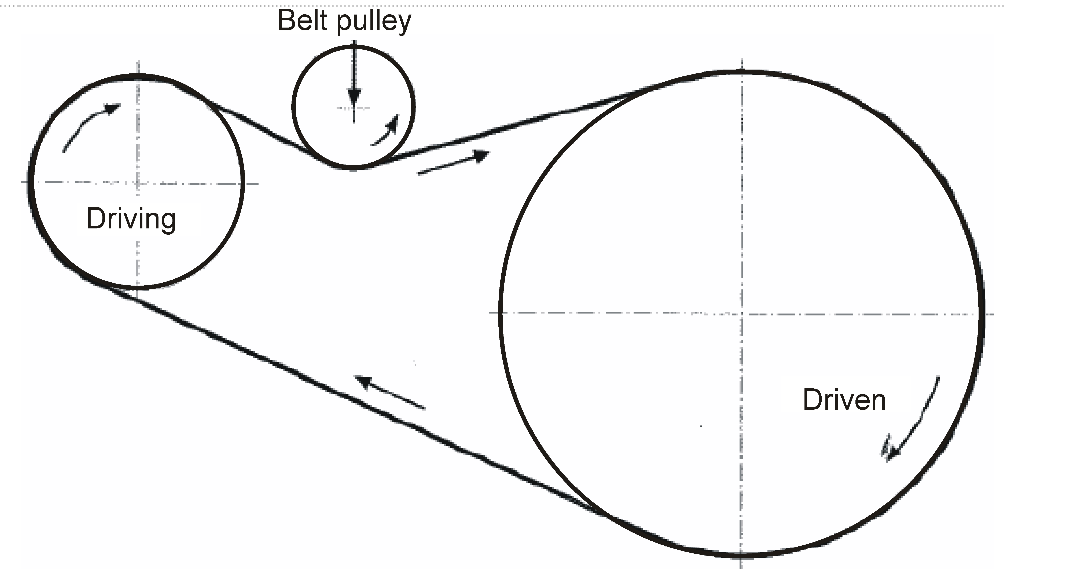

V-belt designs:

a) Standard V-belt, b) Narrow V-belt, c) Narrow V-belt – open-edged, toothed,

d) Wide V-belt (toothed), e) Double V-belt, f) Joined V-belt, g) Poly V-belt

To increase the flexibility of the belt, multiple toothed V-belts are used, enabling smaller diameters. When loaded, the V-belt pulls itself into the trapezium shaped groove of the pulley and generates the friction contact required for torque transmission through the V-effect on both edges. The V-belt itself may not touch the bottom of the groove.

为了增加皮带的灵活性,使用了多个齿形 V 形皮带,从而实现更小的直径。加载时,V 形皮带将自身拉入滑轮的梯形槽中,并通过两侧 V 效应产生扭矩传输所需的摩擦接触。V 形皮带本身可能无法触及凹槽的底部。

The fact that high standard forces between pulleys and belts occur at low pretension (thereby offering a good friction connection) offers advantages for the V-belt. These advantages include low bearing load and reliable operation even in the case of small angles of contact. The V-belt is less efficient in comparison with the flat belt, as it is restricted by the high amount of flexing required and the associated significant temperature increase of the belt.

滑轮和皮带之间的高标准力以低预紧(从而提供了良好的摩擦连接)发生,这一事实为 V 形皮带提供了优势。这些优点包括低轴承负载和可靠的操作,即使在小接触角度的情况下。与扁平皮带相比,V 型皮带的效率较低,因为它受到所需的大量弯曲量和相关带温度显著升高的限制。

With few exceptions, V-belts are manufactured as endless and supplied in standard lengths. Shaft spacing can therefore not be freely selected for the design of the V-belt gearbox. For installation reasons, certain constructive precautions are also to be taken.

除了少数例外,V 形皮带是无止境的,以标准长度提供。因此,在 V 带变速箱的设计中不能自由选择轴间距。出于安装原因,我们还要采取某些建设性的预防措施。

posted on 2020-06-27 19:06 lion_zheng 阅读(3823) 评论(0) 编辑 收藏 举报