PS Material 漫谈 八: Bill of Material Transfer

目的:

Bill of material transfer 是用户分配物料给network activities更方便,更保持更新.

如果用手动展开BOM的方法分配BOM items给network activity,一旦BOM有了更改,用户需手动在network下接着做更改.

Bill of material transfer需要很多工作量,尤其当用户

- 想要分配大量components

- 想要在项目设计阶段分配components,同时又想对BOM做多次修改.

在用Bill of material transfer时,系统使用参考点(reference point)创建一个逻辑连接.与手动分配单个物料不同,在BOM transfer时,用户能在network activity下自动更新后续BOM的更改(subsequent BOM changes).

例如,当用户更改了BOM中物料的数量,或描述,用户能自动传输这些更改至network,以及对应的采购需求和预留中. 用户仅需要在项目设计阶段,定期执行分配程序以保持同步.

特性:

BOM类型:

- - Material BOMs

- - Sales order BOMs

- - WBS BOMs

WBS BOMs are mainly used together with  production lots. They are bills of material that are valid only for a particular WBS element. For information on how to create WBS BOMs, refer to

production lots. They are bills of material that are valid only for a particular WBS element. For information on how to create WBS BOMs, refer to  Creating Single-Level Work Breakdown Structure BOM or

Creating Single-Level Work Breakdown Structure BOM or  Creating Multi-Level Work Breakdown Structure BOMs. (Note that if you want to use WBS BOMs with the Project System, it is not necessary to create production lots)

Creating Multi-Level Work Breakdown Structure BOMs. (Note that if you want to use WBS BOMs with the Project System, it is not necessary to create production lots)

- - BOMs from external systems

You can select activities from all the networks in a project. You can select complete assemblies or single items; you can also assign BOM items that do not have a reference point. You use various criteria to select the items, for instance by selecting according to BOM usage you can exclude certain assemblies from the selection.

You can use BOM transfer to assign text items or assign material components with material number "0".

You can use assembly items to identify assemblies created in the network.

You can simulate assignments by running the assignment program, and then changing the results afterwards or not saving the results or the changes.

操作:

After a BOM item has been successfully assigned to a network, the system generates requirements if the requirements have been activated.

The system uses the execution factor in the network activity to determine the required amount. You can decide whether the system generates real requirements (purchase requisitions or reservations) or preliminary requirements (preliminary purchase requisitions or planned independent requirements).

For the assignment of a large number of components using BOM transfer, you can use priorities for stock types in inventory management . In this manner you can, for example, determine that components should be managed in sales order stock if possible or, if the component does not allow this, in plant stock.

This means that you can assign costs to another WBS element than that to which the activity is assigned. If the components are kept in project stock, the stock segment changes.

Assigning BOM Items using Bill of Materials Transfer

- You can only assign reference points for items in a bill of material, not for the component in the header. You can only assign such components as Assembly Items.

- You cannot assign BOM items to a standard network using reference points. You can however enter reference points in the data fields which have been defined for this purpose, so that when you use this standard network to create an operative network the system also copies the reference points.

- During assignment using reference points, the system ignores material components that you have already manually assigned to a network activity. These material components do not appear in the list of assignments.

前提:

为了使用BOM transfer, 需满足以下设置

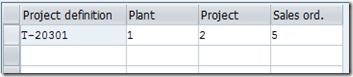

1. 所有你想要分配物料的network activities, 必须分配给WBS element. 你可以使用项目中各个WBS elements. The system ignores the WBS assignment of the network header. In Transfer Control, you can assign individual material components to other WBS elements (than the WBS element in the network header).

2. Network必须分配给销售订单.

流程:

1. Maintaining Reference Points in the Bill of Material Item

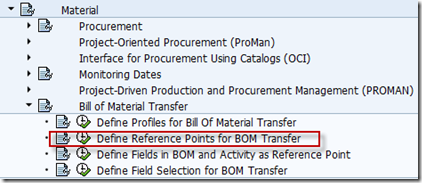

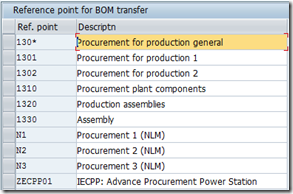

1.1 首先要设置reference point

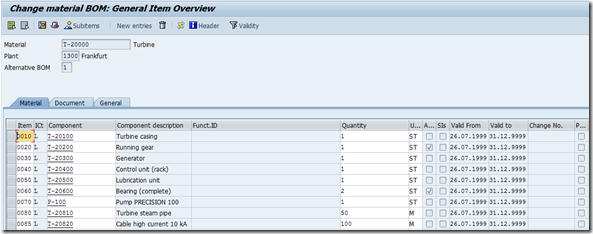

1.2 CS02 (Material BOM)or CS62(Order BOM), or CS72(Single WBS BOM), CS75(Multilevel WBS BOM).

1.3 Enter the relevant data on the initial screen and choose  . The item overview appears.

. The item overview appears.

1.4 Go to the detail screen of the item by double-clicking on the relevant item number. Enter a reference point in the Basic data tab page. You can only enter reference points that have been defined in Customizing for the Project System.

1.5 Save the BOM.

- The reference point in the BOM item must agree with the reference point in the network activity.

- Several bill of material items may have the same value as a reference point however only one network activity may have this value. During assignment, the system checks whether the reference point in the selected network is unique

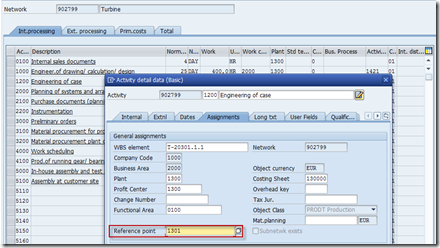

2. Maintaining the Reference Point in the Network Activity

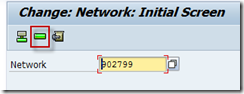

2.1 CN22, Choose  .

.

2.2 Select the required activities and double-click on the activity numbers to access the activity detail screen. Enter a reference point on the Assignments tab page.

2.3 You can move between activities with

or choose

or choose  . Save the network.

. Save the network.

- The reference point in the network activity must agree with the reference point in the BOM item.

- Several bill of material items may have the same value as a reference point however only one network activity may have this value. During allocation, the system checks whether the reference point in the selected network is unique.

- It is possible to use generic entries for the reference point in network activities. However, in contrast to earlier versions (before Release 4.6), you must define the generic reference point in Customizing first. For instance, you have used reference points b12, b13, b14, and b15 in BOM items and want to assign all these items to one activity. You can define a reference point b* or b1* in Customizing and assign it to the activity. All of the BOM items are then assigned to the activity.

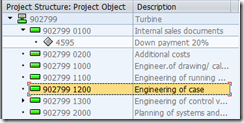

3. Executing the Allocation Program in BOM Transfer

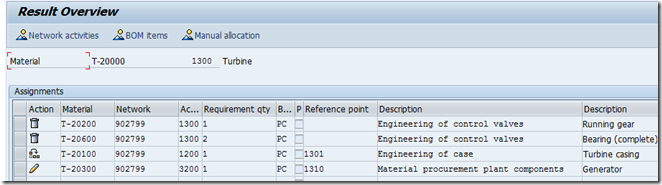

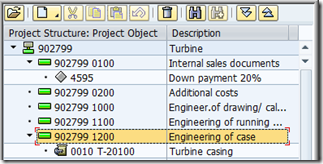

Activity1200是没有物料的

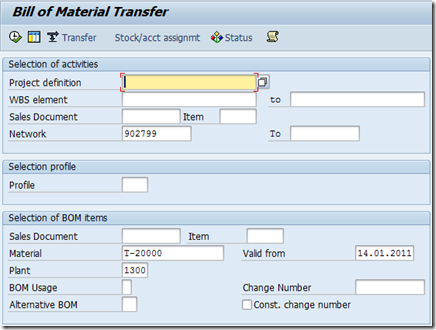

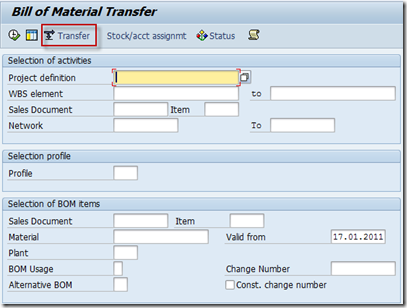

3.1 CN33

For activity selection enter a project definition, a WBS element, a range of WBS elements, a sales document item, a network, or a range of networks. If applicable, enter a profile you have created in Customizing and choose ![]() .

.

The system copies the selection parameters from the profile.

You do not have to create a profile, but this is helpful, if you use the same settings frequently.

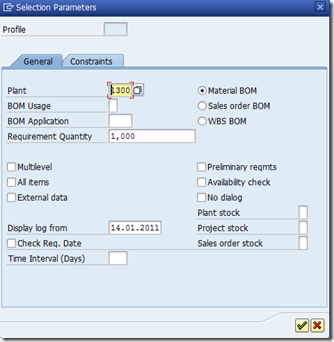

To display, and if required change, the selection parameters, choose ![]() . For more information, read Selection Parameters .

. For more information, read Selection Parameters .

3.2 Enter the material for the selection of the BOM items. In the selection parameters you must select the relevant BOM category: Material BOM, Sales order BOM, or WBS BOM.

Always perform the allocation on the top level of the BOM so that the system can identify items that are used several times, for instance for changes in quantity.

3.3 Choose ![]() .

.

The system selects the BOM items and network activities based on your criteria and automatically allocates all items with reference points.

-

- If the system cannot allocate all items, the Manual Assignments screen appears, where you can assign the remaining components manually.

You can also call up an overview of the selected network activities and BOM items from the results overview.

3.4 Save your assignments.

If you have not predefined priorities in inventory management , the system will display a dialog box where you can choose the appropriate stock.

3.5 When you save, the system allocates the BOM items to network activities and if applicable, generates the corresponding (preliminary) requirements.T-20100 is transfered.

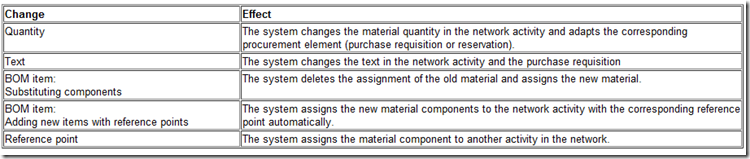

The Effects of Changes in BOMs and BOM Transfer

1. If you are using BOM transfer and change a BOM, the network activity will be up-dated with these changes the next time you execute the assignment program.

2. The system also updates the purchase requisitions and reservations generated by the network

Effect of changes in BOMs when using the assignment program in BOM transfer

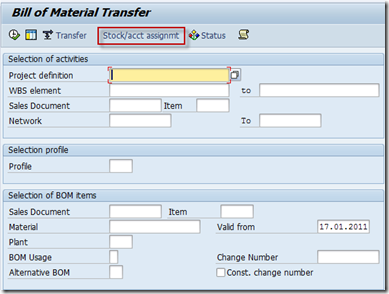

Setting Priorities for Inventory Management

使用:

在分配一个能使用在多种不同库存类型的物料时, 对话框会跳出询问该物料应该属于哪种库存类型(stock type).

用户可以预设物料的库存类型.

流程:

1. CN33, Choose Stock/acct. assignmt..

2. Enter the project definition of the project for which you want to set priorities for the stock type.

Enter the priority for the stock. For instance, with priority 1 for project stock and 2 for plant stock, you specify that the system should manage all material components in project stock. If this not possible, they should be managed in plant stock.

Defining Assembly Items for BOM Transfer

使用:

Use transfer control to define components as assembly items in BOM transfer.

The transfer control has two functions:

- A: You can define material components as assembly items using reference points as described below.

- B: You can assign individual material components to other WBS elements than the WBS element that the network activity is assigned to. See Assigning Material Components to Other WBS Elements

流程:

1. CN33, Choose  Transfer.

Transfer.

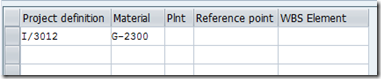

2. Enter the project in which you want to assign an assembly item. Enter the material and reference point.

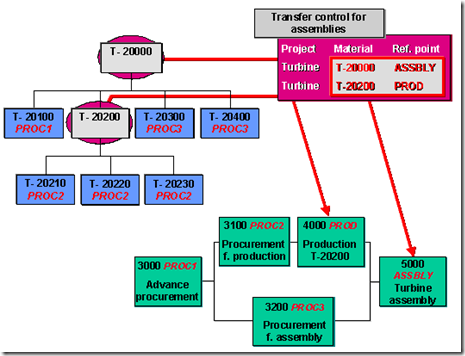

BOM Transfer: Example

1. 目的:

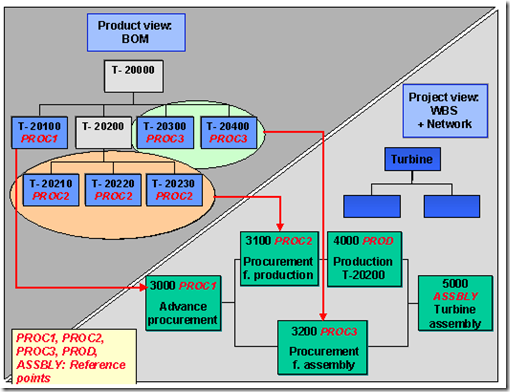

使用network来生产,组装一个涡轮. 使用BOM transfer功能将BOM item从一个二级BOM分配到不同的network activities.

Item T-20100 is a directly procured material (item category N) with a long delivery time. It is assigned via the reference point PROC1 to activity 3000"Advance procurement"

The sub-items T-20210, T-20220, T-20230 for the production of assembly T-20200 are to be procured in activity 3100. Since these BOM items are all procured in the same activity, they have the same reference point PROC2.

Turbine assembly also requires material component T-20300 and T-20400 that are procured using MRP (item category L). They are assigned via the reference point PROC3 to activity 3200.

2. Assembly Items:

Instead of using production orders, the production of assemblies can be modeled using assembly items. In the transfer table you enter the project, the assembly to be produced and the reference point of the activity in which the assembly is produced.

In this example, assembly T-20200 is produced in activity 4000 with reference point PROD, and turbine T-20000 is assembled in activity 5000 with reference point ASSBLY. The system assigns these assembly items with quantity -1 ("receipt from activity") and sets the requirements date to the finish date of the activity.

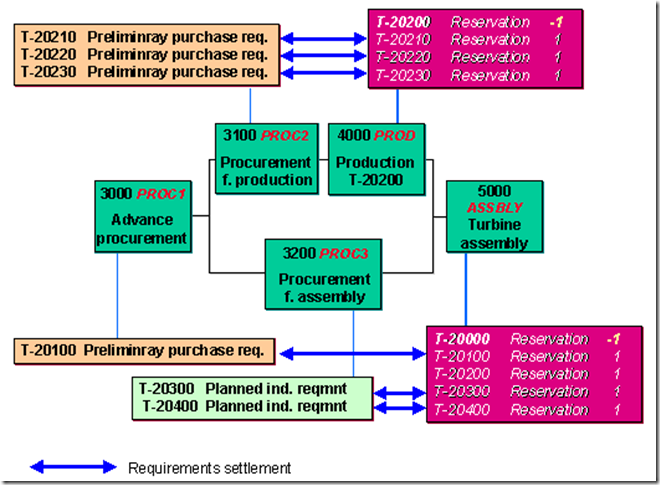

3. Allocation and Material Requirements Planning (MRP)

After you have defined reference points in the BOM and the network activities, and the assignment in transfer control, you execute the BOM transfer assignment program.

You enter as selection parameters the Project definition, the Material T-20000 and set the Multi-level and Preliminary reqmnts indicators.

The system assigns the BOM items to the network activities and when the system activates requirements, it generates reservations and preliminary requirements as follows:

- 3.1 In activities 5000 and 4000 reservations are created for the assembly items T-20000 and T-20200 with quantity -1 in both cases. The "requirements date" is the finish date of the respective activity.

- 3.2 Although the Preliminary reqmnts indicator is set, real requirements are generated for the subordinate components in the assembly items in the form of reservations for the activity start date.

- 3.3 As a result, reservations (dependent requirements) are generated for components T-20210, T-20220, and T-20230 in activity 4000. These components are consumed during the assembly of T-20200. However, since these components have a different reference point than the superior assembly, with which they are assigned to activity 3100, preliminary requirements are generated in activity 3100. In the case of externally procured components these are preliminary purchase requisitions.

- 3.4 Similarly, preliminary requirements are generated for the components, for which dependent requirements are generated in activity 5000, but which are assigned via reference points to other activities. If the components are procured via MRP, the preliminary requirements are planned independent requirements, as in the example for T-20300 and T-20400.

As illustrated in the following graphic, the system settles preliminary requirements against the reservations that are generated later. The prerequisite for this is that the material is managed in the same individual stock segment in both activities, that is. both activities are assigned to the same WBS element