PS Material 漫谈 三: 分配给network的物料

使用:

如果项目中只有一些物料,可以用手动添加的方法将物料分配给network. 如果这些物料是在BOM里的, 用户可以在network activity,一级级或者全部打开BOM(explode the BOM).

反之如果物料不在BOM里,用户则不可使用BOM explosion或BOM transfer的方法分配物料.

特性:

1. 需求时间和需求数量

1.1 在物料分配时,用户指定需求时间(requirements date)和需求数量.

1.2 用户也可以指定负的数量,其结果是分配assembly items, 即稍后在network组装.之后,需求时间自动设成activity的结束时间, 然后货物移动则是一种从netword到stock的物料收货..

如果物料在network activity下生产或组装, 之后被使用(譬如用在发货上), 该物料被视作assembly items

Assembly item是在network activity下创建的,被认为是种负数量的预留.当分配assembly item到network activity时,assembly item的收货日期自动被设成activity的结束日期.

用户可以用手动输入负数需求将Assembly item分配到network activity,也可以使用BOM Transfer.

1.3 用户可使用在network headers or activities下的Execution Factors 将需求数乘以常量.

2. 库存管理和采购

如果对于库存管理和采购有多个选择,在物料分配时会有一个对话框,让用户选择:

- In which stock type the component in managed

- Whether advance procurement is possible

- Whether a directly procured component is a third party order and, in this case, if the component is delivered to the customer or the construction site

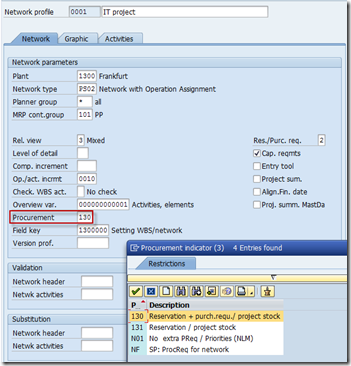

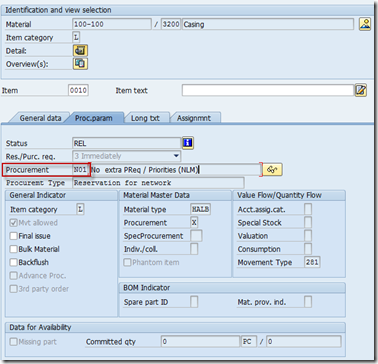

用户可定义procurement indicator(见上一章3.2). 在network profile可将procurement indicator设成默认值,或者在物料分配时输入.

分配后,用户将无法更改procurement indicator.

However you can, even if you have used a procurement indicator, change individual settings as long as the activity has not been released. To do this, select the component and choose Component --> Change account assignment. If there is already a purchase order or reservation for a component, a warning appears.

手动分配物料给Network

1. 输入material, required quantity, unit of measure, item category and choose Enter.

Depending on the settings in the material master and the assignments of the network or activity, a dialog box

may appear in which you enter:

- If the material is managed in different stocks, the stock type (see Managing Stocks of Material Components)

- If the prerequisites to do so are met, you can generate preliminary requirements (see Advance Procurement)

- If the component are directly procured, you can create a third-party order. In this case the material is delivered directly from the vendor to the customer

2. Enter the necessary data for all the material components.

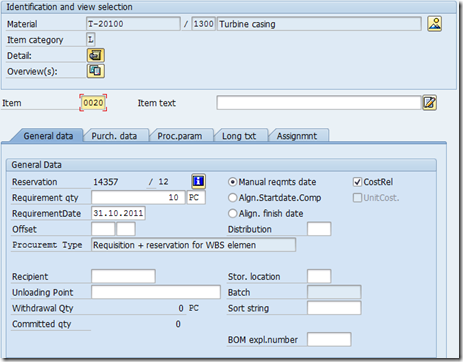

当item category L,在General Data标签页, 用户可以看到reservation number和reserved quantity (required quantity). If you align the requirements to the start or finish date of the activity, you can enter an offset (see Requirements Date).

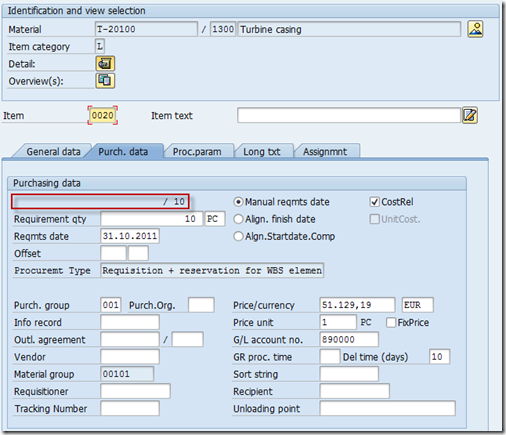

For material that is procured directly, you can see information about whether a purchase requisition has been created in the Purchasing data detail screen, if requirements have been activated. You can go to the purchase requisition by choosing Purch. Req. .

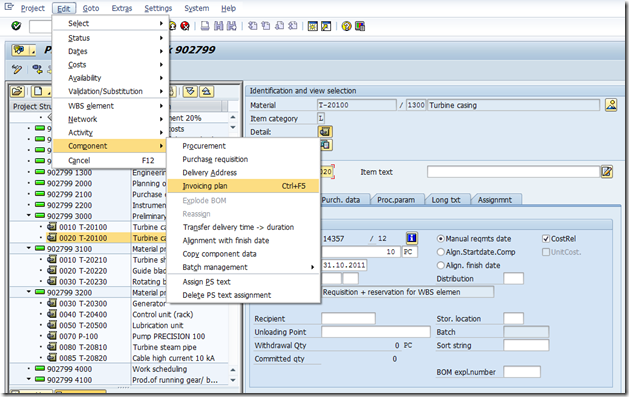

You can plan dates and values for payments by choosing Invoicing plan.

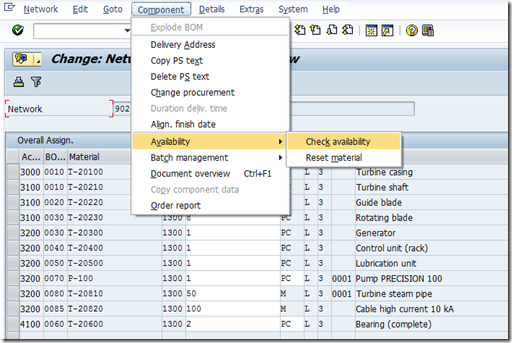

3. To check material availability, choose Component --> Check availability.

Requirements Date Determination

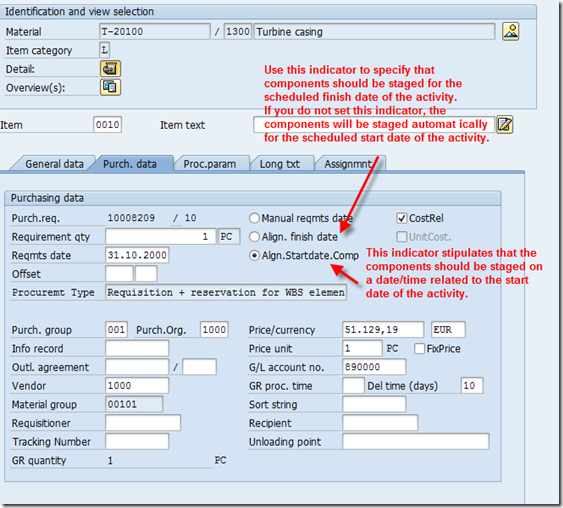

当用户分配物料给network activity, 用户可以决定需求时间与activity时间的偏移(offset),或者手动输入一个固定需求时间. 用户可以在BOM中预设对于activity时间的偏移量.通过activity时间对于需求时间的校正,用户可以保证需求时间会被自动调整,即使activity时间被重新计划了.

1. Aligning a Requirements Date to an Activity Date

You specify on the component detail screen in the Quantity/Reservation section whether the requirements date is aligned with the start date or the finish date of the activity.

Align. Fin. Date: stage components based on finish date

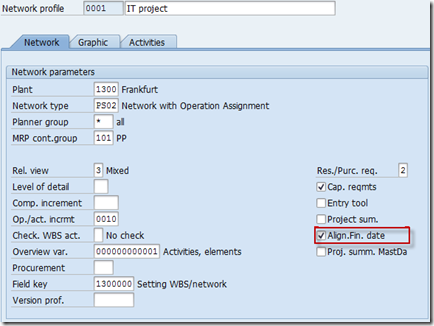

如果在network profile不设Align. Fin. Date,系统默认使用start date.

Offset: 用户可以决定在activity前或后多久,物料要到达.(staged). 负数表示在activity date前,正数表示之后.

举例: Setting Align. Fin. Date with an offset of -2 Days means the component is staged 2 days before the activity finish date.

2. Entering an Offset in the Bill of Material

You can predefine an offset on the item detail screen of the BOM. This offset refers to the start date or the finish date of the activity the component is assigned to, depending on the settings in the network.

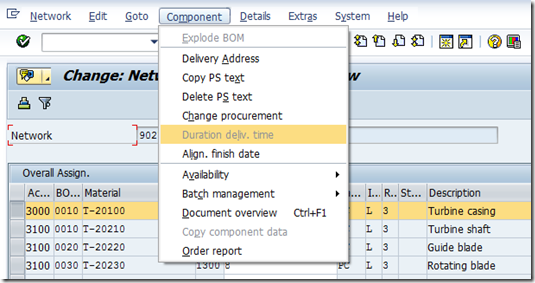

Aligning Activity Duration with Material Lead Time

当计算总的lead time, 系统仅考虑那些设了Align.Fin.date的物料. 所以要先设标记Align. Fin.date,然后

The system determines the whole procurement lead time and the maximum duration of the activity from the following factors.

- The planned delivery time of externally procured material components

- Total replenishment lead time for internally produced components or the in-house production time, if the total replenishment lead time has not been entered on the relevant MRP tab page.

Procurement Using an External Procurement System

You can transfer material components or services for which you want to create a purchase requisition (PReq) from an external catalog using the open catalog interface (OCI) (see Catalog Interface (OCI- Open Catalog Interface)).

前提:

· You installed the SAP R/3 Plug-in for the EBP.

· In the Customizing of the Plug-In system, under Supplier Relationship Management ® Planning-Controlled Procurement, you determined in which system (external procurement system or SAP system) purchase order handling for a purchase requisition should take place.

You can also use the Customer Exit BBPK0001 and thus determine your own logic in the purchasing profile.