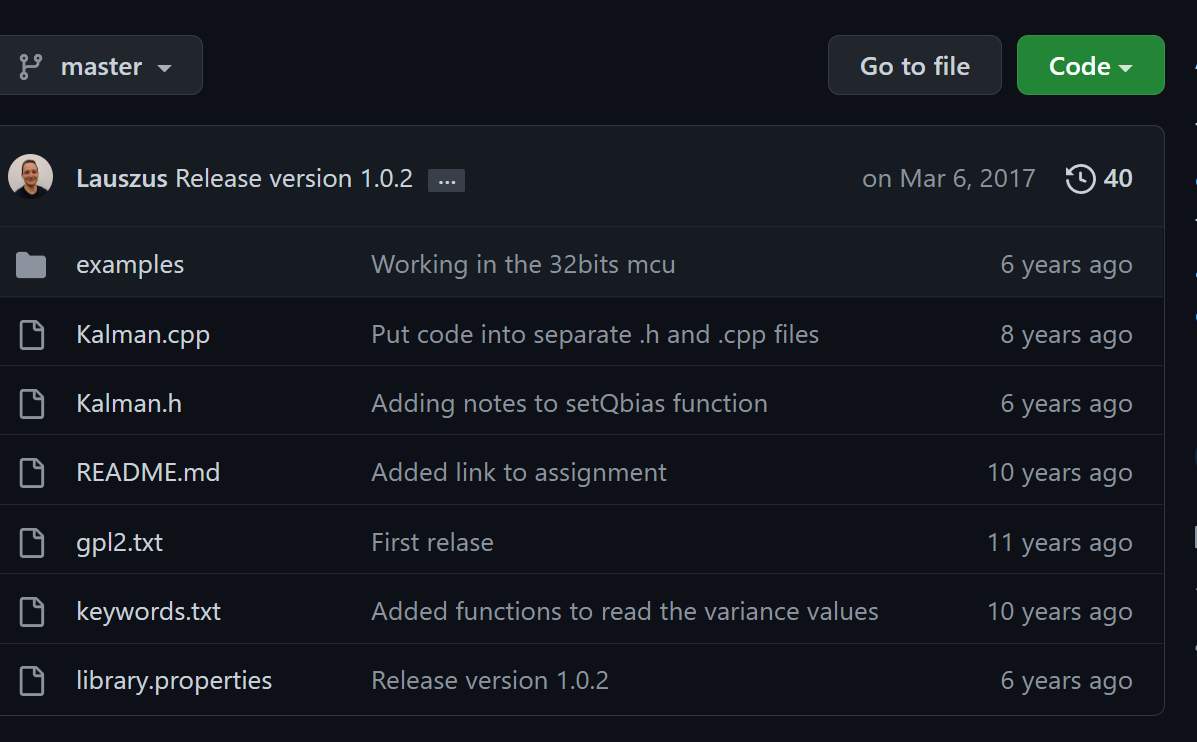

代码

https://github.com/TKJElectronics/KalmanFilter

原理剖析

原理2 卡尔曼融合滤波

https://zhuanlan.zhihu.com/p/36374943

关键点

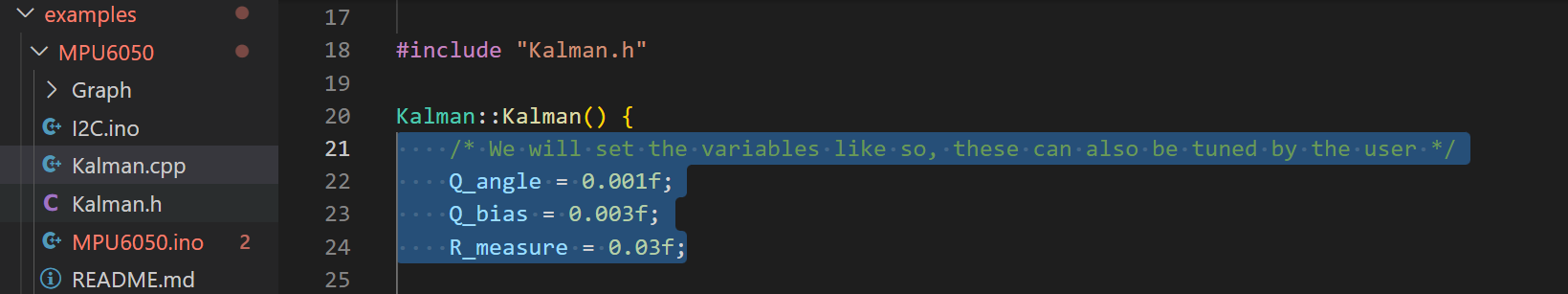

1 他的偏置和噪声方程 根据经验给了数值

经过验证,初始参数设置为以下值时适用于大多数的IMU,并且这些初始参数将会使mpu6050工作在最佳状态;

1 2 3 | float Q_angle = 0.001;float Q_gyroBias = 0.003;float R_measure = 0.03; |

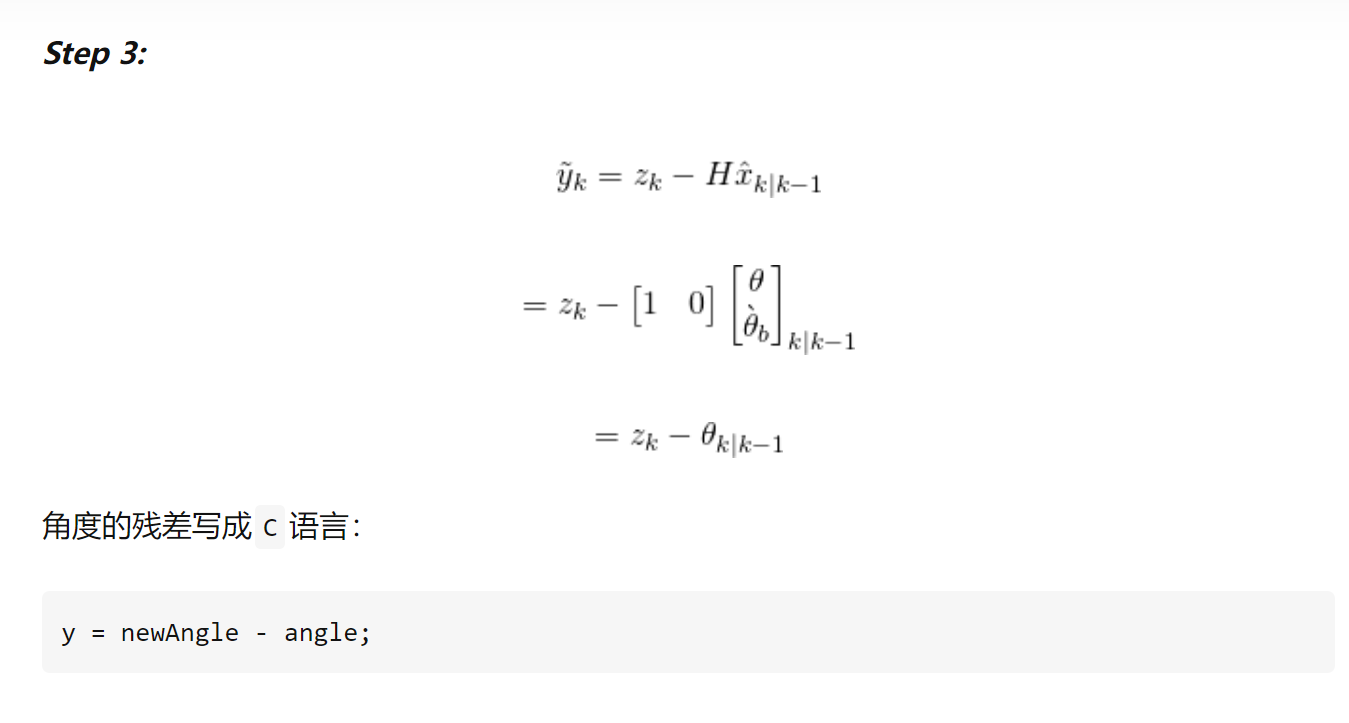

2 误差的计算 测量值-预测值

状态转移矩阵是1

测量值z 使用x和y相对于z轴重力的arctan计算的

1 2 3 4 5 6 7 | #ifdef RESTRICT_PITCH // Eq. 25 and 26 double roll = atan2(accY, accZ) * RAD_TO_DEG; double pitch = atan(-accX / sqrt(accY * accY + accZ * accZ)) * RAD_TO_DEG;#else // Eq. 28 and 29 double roll = atan(accY / sqrt(accX * accX + accZ * accZ)) * RAD_TO_DEG; double pitch = atan2(-accX, accZ) * RAD_TO_DEG;#endif |

进一步算残差

1 | kalAngleX = kalmanX.getAngle(roll, gyroXrate, dt); |

原理1 IMU本身运行和坐标系转换积分原理

IMU姿态解算

IMU,即惯性测量单元,一般包含三轴陀螺仪与三轴加速度计。之前的文章

https://zhuanlan.zhihu.com/p/165156300

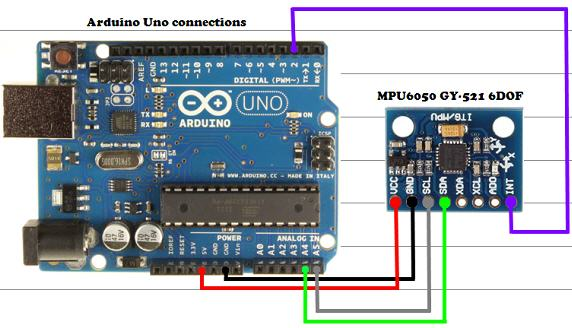

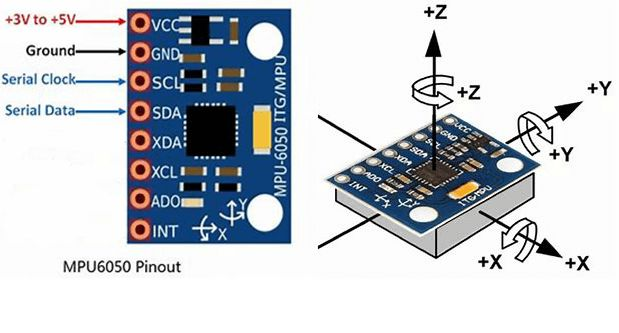

MPU6050基本功能

- 3轴陀螺仪

陀螺仪,测量的是绕xyz轴转动的角速度,对角速度积分可以得到角度。

- 3轴加速度计

加速度计,测量的是xyz方向受到的加速度。在静止时,测量到的是重力加速度,因此当物体倾斜时,根据重力的分力可以粗略的计算角度。在运动时,除了重力加速度,还叠加了由于运动产生的加速度。

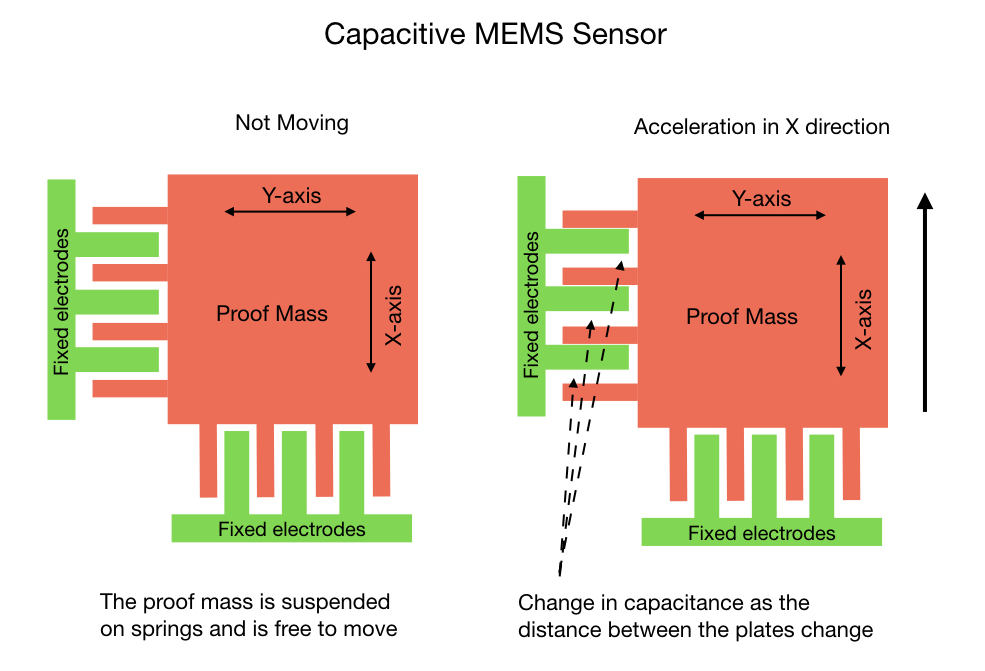

工作原理

但是更大的加速度计图将有助于显示正在发生的事情。

所谓的证明质量悬挂在弹簧上,并在设备加速时自由移动。固定的电极梳在自身和检测质量之间建立电容效应。当设备移动时,电容的变化会被记录并由 ADC 转换为 0 到 32,750 之间的数字值。陀螺仪以类似的方式工作,只是它基于科里奥利效应而不是加速度。

设备灵敏度

正如刚才提到的,从电容传感器读取的模拟电压被转换为 0 到 32750 值范围内的数字信号。这些值构成了陀螺仪和加速度计的测量单位。必须拆分测量单位以表示有意义的信息。MPU6050 _通过创建四个灵敏度级别来分配其测量单位,如下面的幻灯片所示。您选择的敏感级别取决于您将如何使用 IMU。例如,如果机器人要进行每秒超过 1000° (167 RPM) 的高速旋转,则应将陀螺仪灵敏度设置为 2000°。在这种情况下,由于陀螺仪必须在很短的时间内覆盖大量旋转地面,因此需要谨慎地拆分其测量单元。然而,对于大多数应用,机器人不太可能旋转得那么快,因此我们可以将灵敏度级别设置为 250°,这是默认设置。这为我们提供了每秒每度 131 个测量单位,从而提供了非常高的精度水平。

加速度计的默认设置为 2g。这应该适用于 F14 以外的大多数应用程序或构建 Tesla 的机械臂。

DMP简介

DMP就是MPU6050内部的运动引擎,全称Digital Motion Processor,直接输出四元数,可以减轻外围微处理器的工作负担且避免了繁琐的滤波和数据融合。Motion Driver是Invensense针对其运动传感器的软件包,并非全部开源,核心的算法部分是针对ARM处理器和MSP430处理器编译成了静态链接库,适用于MPU6050、MPU6500、MPU9150、MPU9250等传感器。

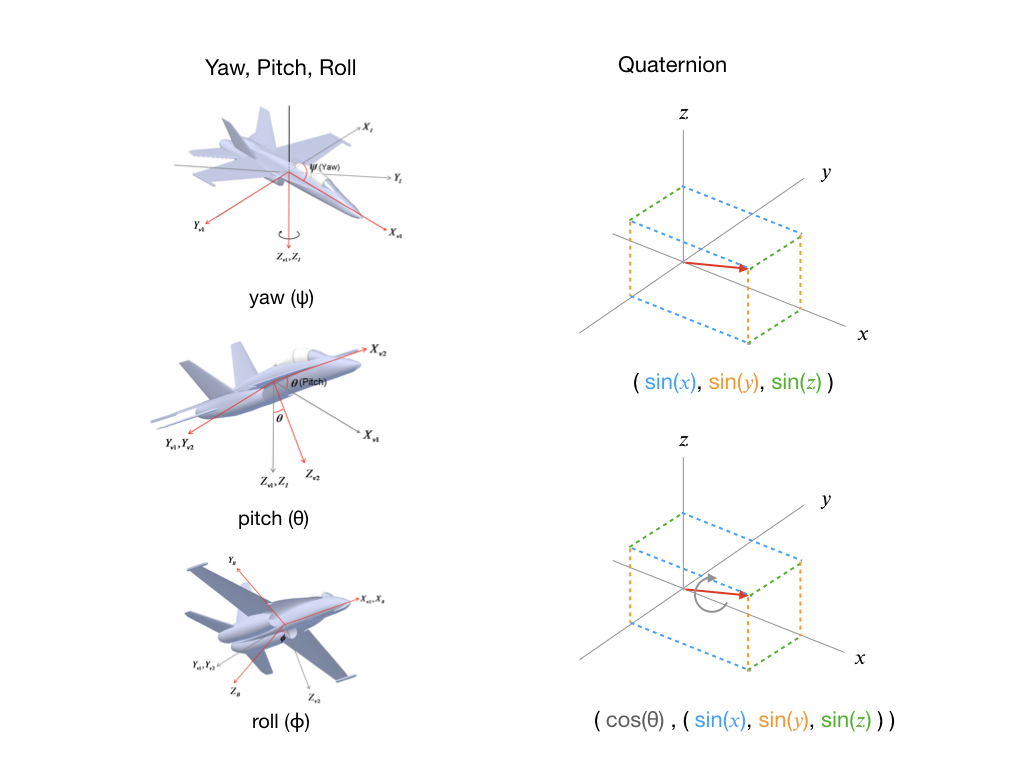

四元数

要理解四元数,将它们与 Yaw、Pitch、Roll 进行比较是很有用的,这是大多数人更熟悉的概念。要表示方向的变化,您首先要指定偏航角,即围绕 z 轴的旋转。然后加上Pitch,也就是绕y轴旋转。最后绕 x 轴滚动。当然,飞机可能会以不同的顺序执行此操作,或者更有可能同时执行此操作,但最终结果仍然是方向发生变化。这里的关键是你只需要三个参数 (ψ, θ, ϕ) 来表示转换。

将此与莫名其妙地需要四个参数的四元数进行对比。所以四元数首先要使用一个向量并将它指向你需要去的方向。这由下图中的红色箭头表示,并且始终是一个单位的长度。由于箭头可以指向 3D 空间中的任何地方,我们需要三个参数来定义它。方向参数以sines形式给出。一旦我们有了方向,我们就可以执行一个滚动来让我们到达最终方向。这就是第四个参数的目的。它以度数(或弧度)指定我们需要旋转多少。

为了确保方向数据对所有应用程序都有用,DMP将其计算存储为四元数。Jeff Rowberg 的程序为您提供了一种将四元数转换为其他有用信息(例如欧拉角和线性加速度)的简单方法。

四元数转欧拉角

四元数可以方便的表示3维空间的旋转,但其概念不太好理解,可以先类比复数,复数表示的其实是2维平面中的旋转。

四元数的基本表示形式为:q0+q1*i+q2*j+q3*k,即1个实部3个虚部,具体细节本篇先不做展开介绍。

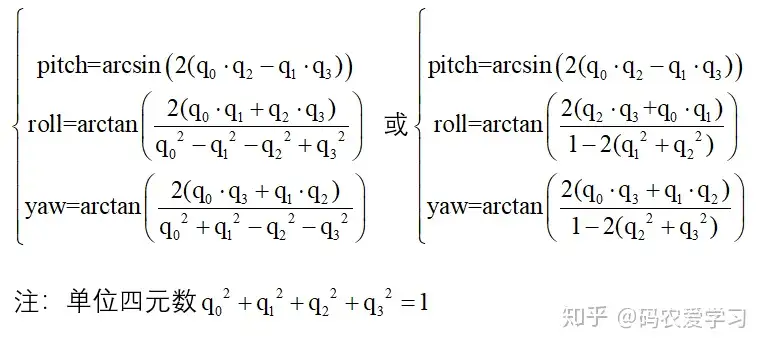

四元数虽然方便表示旋转,但其形式不太直观,旋转转换成pitch、roll、yaw的表示形式,方便观察姿态。

四元数的基本表示形式为:q0+q1*i+q2*j+q3*k,即1个实部3个虚部,具体细节本篇先不做展开介绍。

四元数虽然方便表示旋转,但其形式不太直观,旋转转换成pitch、roll、yaw的表示形式,方便观察姿态。

转换公式为:

https://zhuanlan.zhihu.com/p/195683958

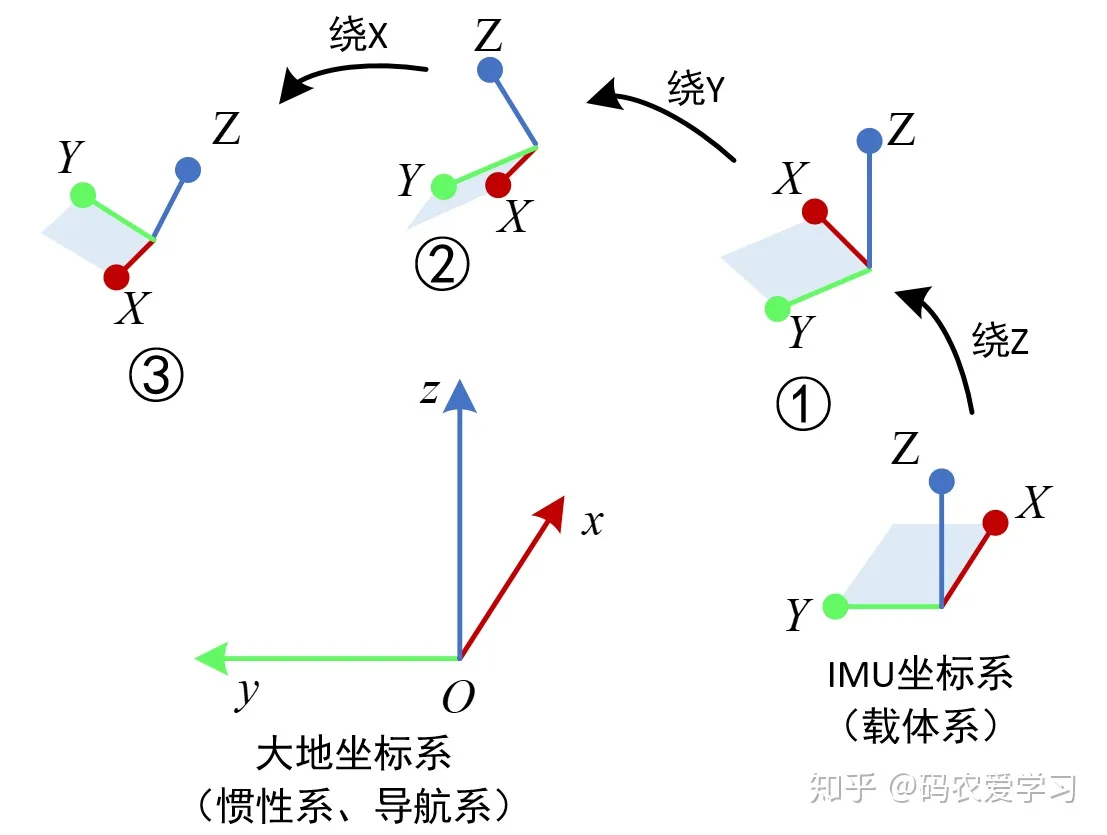

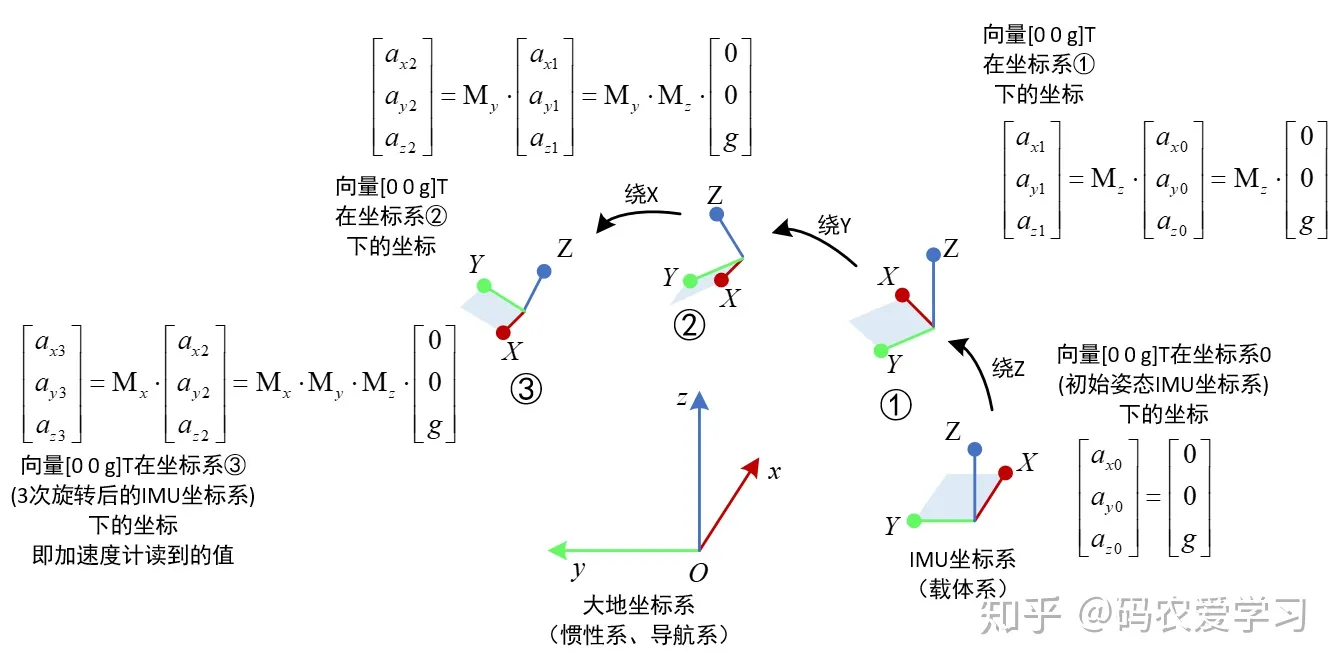

本篇的姿态解算选用的旋转顺序为ZYX,即IMU坐标系初始时刻与大地坐标系重合,然后依次绕自己的Z、Y、X轴进行旋转,这里先自定义一下每次的旋转名称和符号:

- 绕IMU的Z轴旋转:航向角yaw, 转动 y 角度

- 绕IMU的Y轴旋转:俯仰角pitch,转动 p 角度

- 绕IMU的X轴旋转:横滚角row, 转动 r 角度

另外,横滚roll,俯仰pitch,偏航yaw的实际含义如下图:

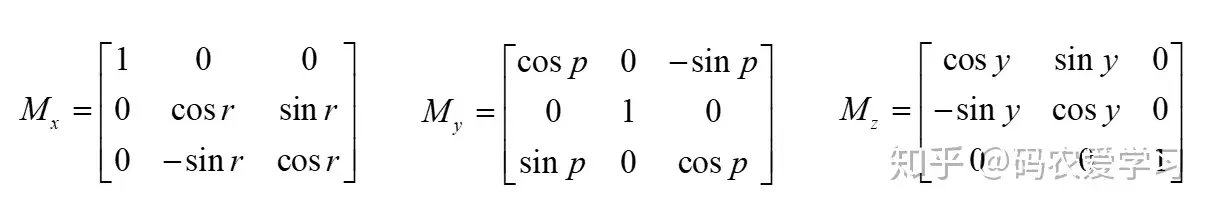

2 旋转矩阵

旋转矩阵的知识请先参阅

这里只列出本篇需要用到的3个旋转矩阵,注意这3个旋转矩阵是坐标变换的旋转矩阵。

程序表示为:

1 2 3 | pitch = asin(-2 * q1 * q3 + 2 * q0* q2)roll = atan2(2 * q2 * q3 + 2 * q0 * q1, -2 * q1 * q1 - 2 * q2* q2 + 1)yaw = atan2(2*(q1*q2 + q0*q3),q0*q0+q1*q1-q2*q2-q3*q3) |

3 欧拉角旋转

欧拉角旋转的知识请先参阅

这里需要说明的是,本篇需要用到的绕着自己运动的轴,以ZYX顺序旋转。

4 加速度计解算姿态角

加速度计测量的是其感受到的加速度,在静止的时候,其本身是没有加速运动的,但因为重力加速度的作用,根据相对运动理论,其感受的加速度与重力加速度正好相反,即读到的数据是竖直向上的。加速度计的英文简写为acc,下面用首字母a代表加速度计数据。

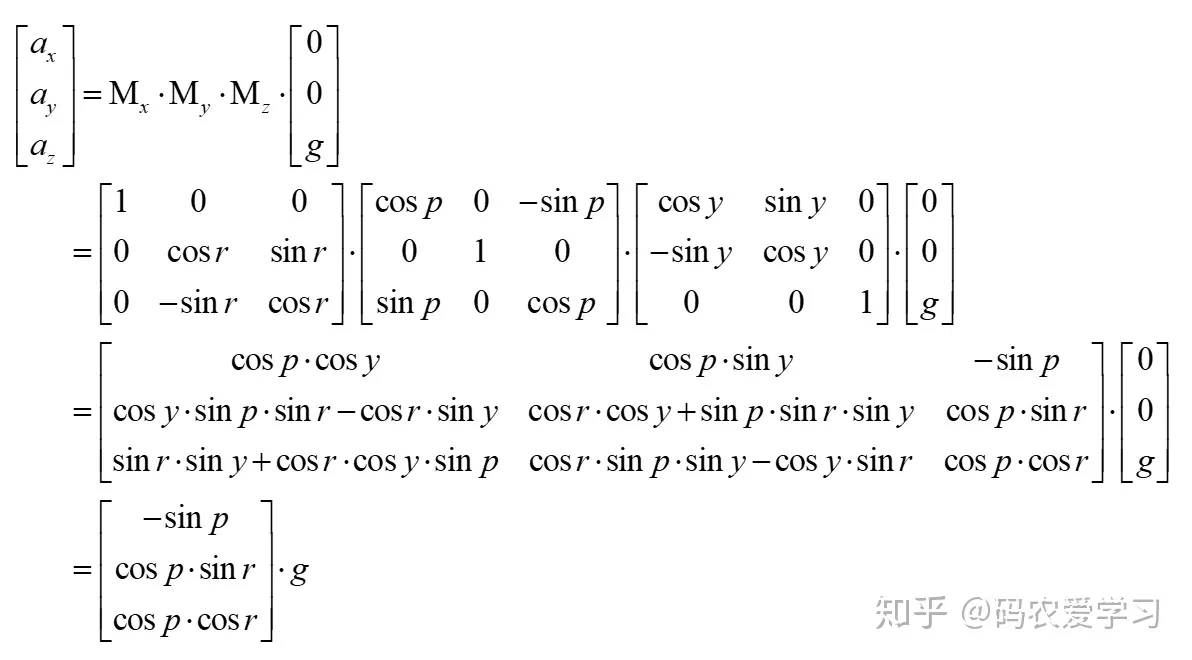

加速度利用静止时刻感受到重力加速度,计算姿态:

- 当加速度计水平放置,即Z轴竖直向上时,Z轴可以读到1g的数值(g为重力加速度),X轴和Y轴两个方向读到0,可以记作(0,0,g)。

- 当加速度计旋转一定的姿态时,重力加速度会在加速度的3个轴上产生相应的分量,其本质是大地坐标系下的(0,0,g)在新的加速度计自身坐标系下的坐标,加速度计读到的3个值就是(0,0,g)向量的新坐标。

姿态的旋转选用ZYX顺序的3次旋转方式,则上述描述可表示为:

解这个方程,可以得到roll和pitch角(由于绕Z旋转时,感受到的重力加速度是不变的,因此加速度计无法计算yaw角)

3次旋转过程的分解过程如下图:

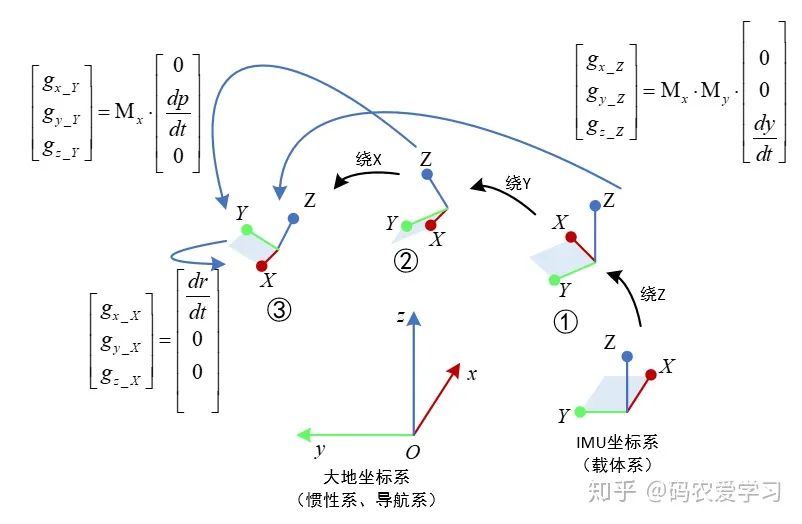

5 陀螺仪解算姿态角

陀螺仪测量的绕3个轴转动的角速度,因此,对角速度积分,可以得到角度。陀螺仪的英文简写为gyro,下面用首字母g代表陀螺仪数据。

如下图,IMU在第n个时刻的姿态角度为r、p、y,其含义为IMU坐标系从初始位置,经过绕Z旋转y角度,绕Y旋转p角度,绕X旋转r角度,得到了最终的姿态,此时需要计算下一个时刻(n+1)的姿态。设n+1时刻的姿态角为r+Δr、p+Δp、y+Δy,该姿态也是经历了3次旋转。要想计算n+1时刻的姿态,只要在n时刻姿态的基础上,加上对应的姿态角度变化量即可。姿态角度的变化量可以通过角速度与采用时间周期积分即可。

这里红框中dr/dt等角速度实际是假想的角速度,用于姿态更新,姿态更新是以大地坐标系为参考,而陀螺仪在第n个状态读出的角速度是以它自己所在的坐标系为参考,需要将读到的gyro陀螺数据经过变换,才能用于计算更新第n+1次的姿态。

那dr/dt等角速度该怎样理解呢?看下面这个图,还是将其分解为3次旋转:

首先来看dy/dt,它是3次旋转过程中绕Z轴的yaw角的角速度,3次旋转首先就是绕着Z轴旋转,Z轴方向的单位向量可表示为[0 0 1]T,T表示向量转置,因此[0 0 dy/dt]T表示在图中状态①的坐标中绕Z的角速度。由于之后该坐标系还要经历绕Y和绕X的两次旋转,因此这里[0 0 dy/dt]T角速度在经历两次旋转后,在最终的坐标系(状态③)中的坐标也要经历两次变换。图中的[gx_Z gy_Z gz_Z]T表示3次旋转过程中绕Z轴的yaw角的角速度在最终姿态中的等效转动角速度,实际就是状态①坐标系中绕Z轴的角速度在状态③坐标系中的新的坐标。

同理,dp/dt还需要经历1次旋转变换,而dr/dt不需要经历旋转。

将dy/dt,dp/dt,dr/dt三者都变换到状态③坐标系中的新的坐标相加,实际就是状态③时刻陀螺仪自己读到的gyro数据。

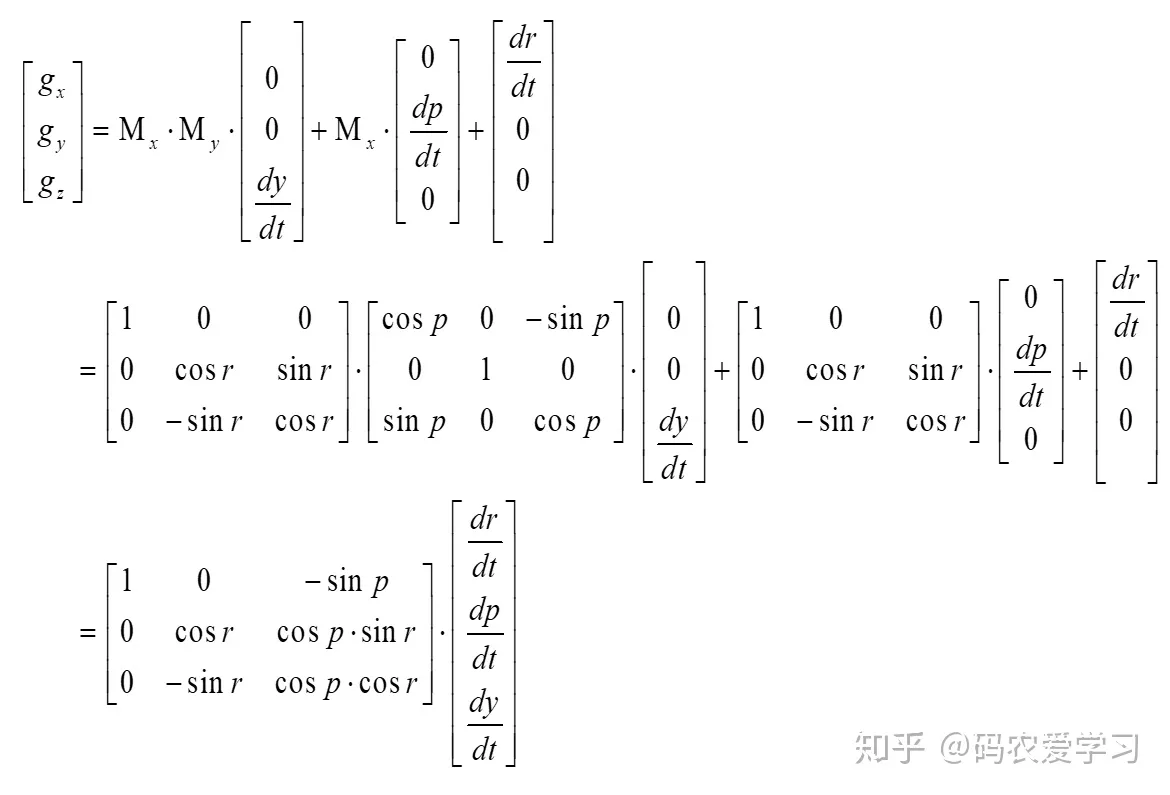

所以,从dr/dt等角速度到陀螺仪读到的角速度gx等的转换关系推导过程如下:

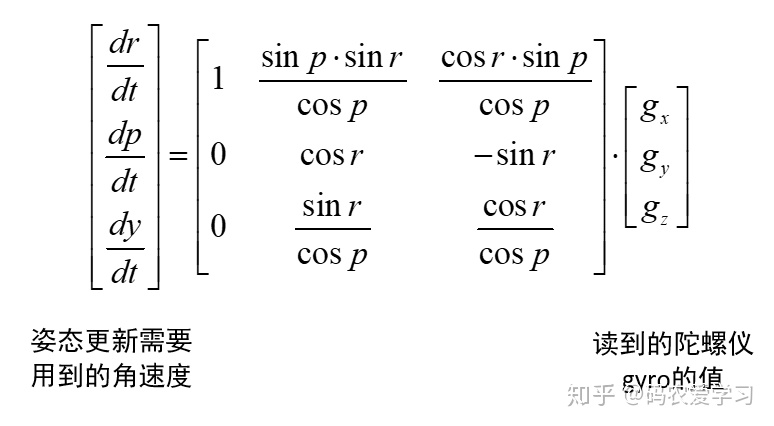

进一步,再把这里的状态③理解为状态n,则根据状态n时刻读到的陀螺仪数据,反解dy/dt等角速度数据,即可更新得到状态n+1的姿态。反解就是求逆矩阵,即:

6 姿态融合

由上面的分析可知,加速度计在静止时刻,根据感受到的重力加速度,可以计算出roll和pitch角,并且角度计算只与当前姿态有关。而陀螺仪是对时间间隔内的角速度积分,得到每一次的角度变换量,累加到上一次的姿态角上,得到新的姿态角,陀螺仪可以计算roll、pitch、yaw三个角。

实际上,加速度仅在静止时刻可以得到较准确的姿态,而陀螺仪仅对转动时的姿态变化敏感,且陀螺仪若本身存在误差,则经过连续的时间积分,误差会不断增大。因此,需要结合两者计算的姿态,进行互补融合。当然,这里只能对roll和pitch融合,因为加速度计没有得到yaw。

K为比例系数,需要根据实际来调整,如选用0.4。

代码

主代码

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 | /* Copyright (C) 2012 Kristian Lauszus, TKJ Electronics. All rights reserved. This software may be distributed and modified under the terms of the GNU General Public License version 2 (GPL2) as published by the Free Software Foundation and appearing in the file GPL2.TXT included in the packaging of this file. Please note that GPL2 Section 2[b] requires that all works based on this software must also be made publicly available under the terms of the GPL2 ("Copyleft"). Contact information ------------------- Kristian Lauszus, TKJ Electronics Web : http://www.tkjelectronics.com e-mail : kristianl@tkjelectronics.com */#include <Wire.h>#include "Kalman.h" // Source: https://github.com/TKJElectronics/KalmanFilter#define RESTRICT_PITCH // Comment out to restrict roll to ±90deg instead - please read: http://www.freescale.com/files/sensors/doc/app_note/AN3461.pdfKalman kalmanX; // Create the Kalman instancesKalman kalmanY;/* IMU Data */double accX, accY, accZ;double gyroX, gyroY, gyroZ;int16_t tempRaw;double gyroXangle, gyroYangle; // Angle calculate using the gyro onlydouble compAngleX, compAngleY; // Calculated angle using a complementary filterdouble kalAngleX, kalAngleY; // Calculated angle using a Kalman filteruint32_t timer;uint8_t i2cData[14]; // Buffer for I2C data// TODO: Make calibration routinevoid setup() { Serial.begin(115200); Wire.begin();#if ARDUINO >= 157 Wire.setClock(400000UL); // Set I2C frequency to 400kHz#else TWBR = ((F_CPU / 400000UL) - 16) / 2; // Set I2C frequency to 400kHz#endif i2cData[0] = 7; // Set the sample rate to 1000Hz - 8kHz/(7+1) = 1000Hz i2cData[1] = 0x00; // Disable FSYNC and set 260 Hz Acc filtering, 256 Hz Gyro filtering, 8 KHz sampling i2cData[2] = 0x00; // Set Gyro Full Scale Range to ±250deg/s i2cData[3] = 0x00; // Set Accelerometer Full Scale Range to ±2g while (i2cWrite(0x19, i2cData, 4, false)); // Write to all four registers at once while (i2cWrite(0x6B, 0x01, true)); // PLL with X axis gyroscope reference and disable sleep mode while (i2cRead(0x75, i2cData, 1)); if (i2cData[0] != 0x68) { // Read "WHO_AM_I" register Serial.print(F("Error reading sensor")); while (1); } delay(100); // Wait for sensor to stabilize /* Set kalman and gyro starting angle */ while (i2cRead(0x3B, i2cData, 6)); accX = (int16_t)((i2cData[0] << 8) | i2cData[1]); accY = (int16_t)((i2cData[2] << 8) | i2cData[3]); accZ = (int16_t)((i2cData[4] << 8) | i2cData[5]); // Source: http://www.freescale.com/files/sensors/doc/app_note/AN3461.pdf eq. 25 and eq. 26 // atan2 outputs the value of -π to π (radians) - see http://en.wikipedia.org/wiki/Atan2 // It is then converted from radians to degrees#ifdef RESTRICT_PITCH // Eq. 25 and 26 double roll = atan2(accY, accZ) * RAD_TO_DEG; double pitch = atan(-accX / sqrt(accY * accY + accZ * accZ)) * RAD_TO_DEG;#else // Eq. 28 and 29 double roll = atan(accY / sqrt(accX * accX + accZ * accZ)) * RAD_TO_DEG; double pitch = atan2(-accX, accZ) * RAD_TO_DEG;#endif kalmanX.setAngle(roll); // Set starting angle kalmanY.setAngle(pitch); gyroXangle = roll; gyroYangle = pitch; compAngleX = roll; compAngleY = pitch; timer = micros();}void loop() { /* Update all the values */ while (i2cRead(0x3B, i2cData, 14)); accX = (int16_t)((i2cData[0] << 8) | i2cData[1]); accY = (int16_t)((i2cData[2] << 8) | i2cData[3]); accZ = (int16_t)((i2cData[4] << 8) | i2cData[5]); tempRaw = (int16_t)((i2cData[6] << 8) | i2cData[7]); gyroX = (int16_t)((i2cData[8] << 8) | i2cData[9]); gyroY = (int16_t)((i2cData[10] << 8) | i2cData[11]); gyroZ = (int16_t)((i2cData[12] << 8) | i2cData[13]);; double dt = (double)(micros() - timer) / 1000000; // Calculate delta time timer = micros(); // Source: http://www.freescale.com/files/sensors/doc/app_note/AN3461.pdf eq. 25 and eq. 26 // atan2 outputs the value of -π to π (radians) - see http://en.wikipedia.org/wiki/Atan2 // It is then converted from radians to degrees#ifdef RESTRICT_PITCH // Eq. 25 and 26 double roll = atan2(accY, accZ) * RAD_TO_DEG; double pitch = atan(-accX / sqrt(accY * accY + accZ * accZ)) * RAD_TO_DEG;#else // Eq. 28 and 29 double roll = atan(accY / sqrt(accX * accX + accZ * accZ)) * RAD_TO_DEG; double pitch = atan2(-accX, accZ) * RAD_TO_DEG;#endif double gyroXrate = gyroX / 131.0; // Convert to deg/s double gyroYrate = gyroY / 131.0; // Convert to deg/s#ifdef RESTRICT_PITCH // This fixes the transition problem when the accelerometer angle jumps between -180 and 180 degrees if ((roll < -90 && kalAngleX > 90) || (roll > 90 && kalAngleX < -90)) { kalmanX.setAngle(roll); compAngleX = roll; kalAngleX = roll; gyroXangle = roll; } else kalAngleX = kalmanX.getAngle(roll, gyroXrate, dt); // Calculate the angle using a Kalman filter if (abs(kalAngleX) > 90) gyroYrate = -gyroYrate; // Invert rate, so it fits the restriced accelerometer reading kalAngleY = kalmanY.getAngle(pitch, gyroYrate, dt);#else // This fixes the transition problem when the accelerometer angle jumps between -180 and 180 degrees if ((pitch < -90 && kalAngleY > 90) || (pitch > 90 && kalAngleY < -90)) { kalmanY.setAngle(pitch); compAngleY = pitch; kalAngleY = pitch; gyroYangle = pitch; } else kalAngleY = kalmanY.getAngle(pitch, gyroYrate, dt); // Calculate the angle using a Kalman filter if (abs(kalAngleY) > 90) gyroXrate = -gyroXrate; // Invert rate, so it fits the restriced accelerometer reading kalAngleX = kalmanX.getAngle(roll, gyroXrate, dt); // Calculate the angle using a Kalman filter#endif gyroXangle += gyroXrate * dt; // Calculate gyro angle without any filter gyroYangle += gyroYrate * dt; //gyroXangle += kalmanX.getRate() * dt; // Calculate gyro angle using the unbiased rate //gyroYangle += kalmanY.getRate() * dt; compAngleX = 0.93 * (compAngleX + gyroXrate * dt) + 0.07 * roll; // Calculate the angle using a Complimentary filter compAngleY = 0.93 * (compAngleY + gyroYrate * dt) + 0.07 * pitch; // Reset the gyro angle when it has drifted too much if (gyroXangle < -180 || gyroXangle > 180) gyroXangle = kalAngleX; if (gyroYangle < -180 || gyroYangle > 180) gyroYangle = kalAngleY; /* Print Data */#if 0 // Set to 1 to activate Serial.print(accX); Serial.print("\t"); Serial.print(accY); Serial.print("\t"); Serial.print(accZ); Serial.print("\t"); Serial.print(gyroX); Serial.print("\t"); Serial.print(gyroY); Serial.print("\t"); Serial.print(gyroZ); Serial.print("\t"); Serial.print("\t");#endif Serial.print(roll); Serial.print("\t"); Serial.print(gyroXangle); Serial.print("\t"); Serial.print(compAngleX); Serial.print("\t"); Serial.print(kalAngleX); Serial.print("\t"); Serial.print("\t"); Serial.print(pitch); Serial.print("\t"); Serial.print(gyroYangle); Serial.print("\t"); Serial.print(compAngleY); Serial.print("\t"); Serial.print(kalAngleY); Serial.print("\t");#if 0 // Set to 1 to print the temperature Serial.print("\t"); double temperature = (double)tempRaw / 340.0 + 36.53; Serial.print(temperature); Serial.print("\t");#endif Serial.print("\r\n"); delay(2);} |

I2C.ino

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 | /* Copyright (C) 2012 Kristian Lauszus, TKJ Electronics. All rights reserved. This software may be distributed and modified under the terms of the GNU General Public License version 2 (GPL2) as published by the Free Software Foundation and appearing in the file GPL2.TXT included in the packaging of this file. Please note that GPL2 Section 2[b] requires that all works based on this software must also be made publicly available under the terms of the GPL2 ("Copyleft"). Contact information ------------------- Kristian Lauszus, TKJ Electronics Web : http://www.tkjelectronics.com e-mail : kristianl@tkjelectronics.com */const uint8_t IMUAddress = 0x68; // AD0 is logic low on the PCBconst uint16_t I2C_TIMEOUT = 1000; // Used to check for errors in I2C communicationuint8_t i2cWrite(uint8_t registerAddress, uint8_t data, bool sendStop) { return i2cWrite(registerAddress, &data, 1, sendStop); // Returns 0 on success}uint8_t i2cWrite(uint8_t registerAddress, uint8_t *data, uint8_t length, bool sendStop) { Wire.beginTransmission(IMUAddress); Wire.write(registerAddress); Wire.write(data, length); uint8_t rcode = Wire.endTransmission(sendStop); // Returns 0 on success if (rcode) { Serial.print(F("i2cWrite failed: ")); Serial.println(rcode); } return rcode; // See: http://arduino.cc/en/Reference/WireEndTransmission}uint8_t i2cRead(uint8_t registerAddress, uint8_t *data, uint8_t nbytes) { uint32_t timeOutTimer; Wire.beginTransmission(IMUAddress); Wire.write(registerAddress); uint8_t rcode = Wire.endTransmission(false); // Don't release the bus if (rcode) { Serial.print(F("i2cRead failed: ")); Serial.println(rcode); return rcode; // See: http://arduino.cc/en/Reference/WireEndTransmission } Wire.requestFrom(IMUAddress, nbytes, (uint8_t)true); // Send a repeated start and then release the bus after reading for (uint8_t i = 0; i < nbytes; i++) { if (Wire.available()) data[i] = Wire.read(); else { timeOutTimer = micros(); while (((micros() - timeOutTimer) < I2C_TIMEOUT) && !Wire.available()); if (Wire.available()) data[i] = Wire.read(); else { Serial.println(F("i2cRead timeout")); return 5; // This error value is not already taken by endTransmission } } } return 0; // Success} |

Kalman.h

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 | /* Copyright (C) 2012 Kristian Lauszus, TKJ Electronics. All rights reserved. This software may be distributed and modified under the terms of the GNU General Public License version 2 (GPL2) as published by the Free Software Foundation and appearing in the file GPL2.TXT included in the packaging of this file. Please note that GPL2 Section 2[b] requires that all works based on this software must also be made publicly available under the terms of the GPL2 ("Copyleft"). Contact information ------------------- Kristian Lauszus, TKJ Electronics Web : http://www.tkjelectronics.com e-mail : kristianl@tkjelectronics.com */#ifndef _Kalman_h_#define _Kalman_h_class Kalman {public: Kalman(); // The angle should be in degrees and the rate should be in degrees per second and the delta time in seconds float getAngle(float newAngle, float newRate, float dt); void setAngle(float angle); // Used to set angle, this should be set as the starting angle float getRate(); // Return the unbiased rate /* These are used to tune the Kalman filter */ void setQangle(float Q_angle); /** * setQbias(float Q_bias) * Default value (0.003f) is in Kalman.cpp. * Raise this to follow input more closely, * lower this to smooth result of kalman filter. */ void setQbias(float Q_bias); void setRmeasure(float R_measure); float getQangle(); float getQbias(); float getRmeasure();private: /* Kalman filter variables */ float Q_angle; // Process noise variance for the accelerometer float Q_bias; // Process noise variance for the gyro bias float R_measure; // Measurement noise variance - this is actually the variance of the measurement noise float angle; // The angle calculated by the Kalman filter - part of the 2x1 state vector float bias; // The gyro bias calculated by the Kalman filter - part of the 2x1 state vector float rate; // Unbiased rate calculated from the rate and the calculated bias - you have to call getAngle to update the rate float P[2][2]; // Error covariance matrix - This is a 2x2 matrix};#endif |

Kalman.cpp

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 | /* Copyright (C) 2012 Kristian Lauszus, TKJ Electronics. All rights reserved. This software may be distributed and modified under the terms of the GNU General Public License version 2 (GPL2) as published by the Free Software Foundation and appearing in the file GPL2.TXT included in the packaging of this file. Please note that GPL2 Section 2[b] requires that all works based on this software must also be made publicly available under the terms of the GPL2 ("Copyleft"). Contact information ------------------- Kristian Lauszus, TKJ Electronics Web : http://www.tkjelectronics.com e-mail : kristianl@tkjelectronics.com */#include "Kalman.h"Kalman::Kalman() { /* We will set the variables like so, these can also be tuned by the user */ Q_angle = 0.001f; Q_bias = 0.003f; R_measure = 0.03f; angle = 0.0f; // Reset the angle bias = 0.0f; // Reset bias P[0][0] = 0.0f; // Since we assume that the bias is 0 and we know the starting angle (use setAngle), the error covariance matrix is set like so - see: http://en.wikipedia.org/wiki/Kalman_filter#Example_application.2C_technical P[0][1] = 0.0f; P[1][0] = 0.0f; P[1][1] = 0.0f;};// The angle should be in degrees and the rate should be in degrees per second and the delta time in secondsfloat Kalman::getAngle(float newAngle, float newRate, float dt) { // KasBot V2 - Kalman filter module - http://www.x-firm.com/?page_id=145 // Modified by Kristian Lauszus // See my blog post for more information: http://blog.tkjelectronics.dk/2012/09/a-practical-approach-to-kalman-filter-and-how-to-implement-it // Discrete Kalman filter time update equations - Time Update ("Predict") // Update xhat - Project the state ahead /* Step 1 */ rate = newRate - bias; angle += dt * rate; // Update estimation error covariance - Project the error covariance ahead /* Step 2 */ P[0][0] += dt * (dt*P[1][1] - P[0][1] - P[1][0] + Q_angle); P[0][1] -= dt * P[1][1]; P[1][0] -= dt * P[1][1]; P[1][1] += Q_bias * dt; // Discrete Kalman filter measurement update equations - Measurement Update ("Correct") // Calculate Kalman gain - Compute the Kalman gain /* Step 4 */ float S = P[0][0] + R_measure; // Estimate error /* Step 5 */ float K[2]; // Kalman gain - This is a 2x1 vector K[0] = P[0][0] / S; K[1] = P[1][0] / S; // Calculate angle and bias - Update estimate with measurement zk (newAngle) /* Step 3 */ float y = newAngle - angle; // Angle difference /* Step 6 */ angle += K[0] * y; bias += K[1] * y; // Calculate estimation error covariance - Update the error covariance /* Step 7 */ float P00_temp = P[0][0]; float P01_temp = P[0][1]; P[0][0] -= K[0] * P00_temp; P[0][1] -= K[0] * P01_temp; P[1][0] -= K[1] * P00_temp; P[1][1] -= K[1] * P01_temp; return angle;};void Kalman::setAngle(float angle) { this->angle = angle; }; // Used to set angle, this should be set as the starting anglefloat Kalman::getRate() { return this->rate; }; // Return the unbiased rate/* These are used to tune the Kalman filter */void Kalman::setQangle(float Q_angle) { this->Q_angle = Q_angle; };void Kalman::setQbias(float Q_bias) { this->Q_bias = Q_bias; };void Kalman::setRmeasure(float R_measure) { this->R_measure = R_measure; };float Kalman::getQangle() { return this->Q_angle; };float Kalman::getQbias() { return this->Q_bias; };float Kalman::getRmeasure() { return this->R_measure; }; |

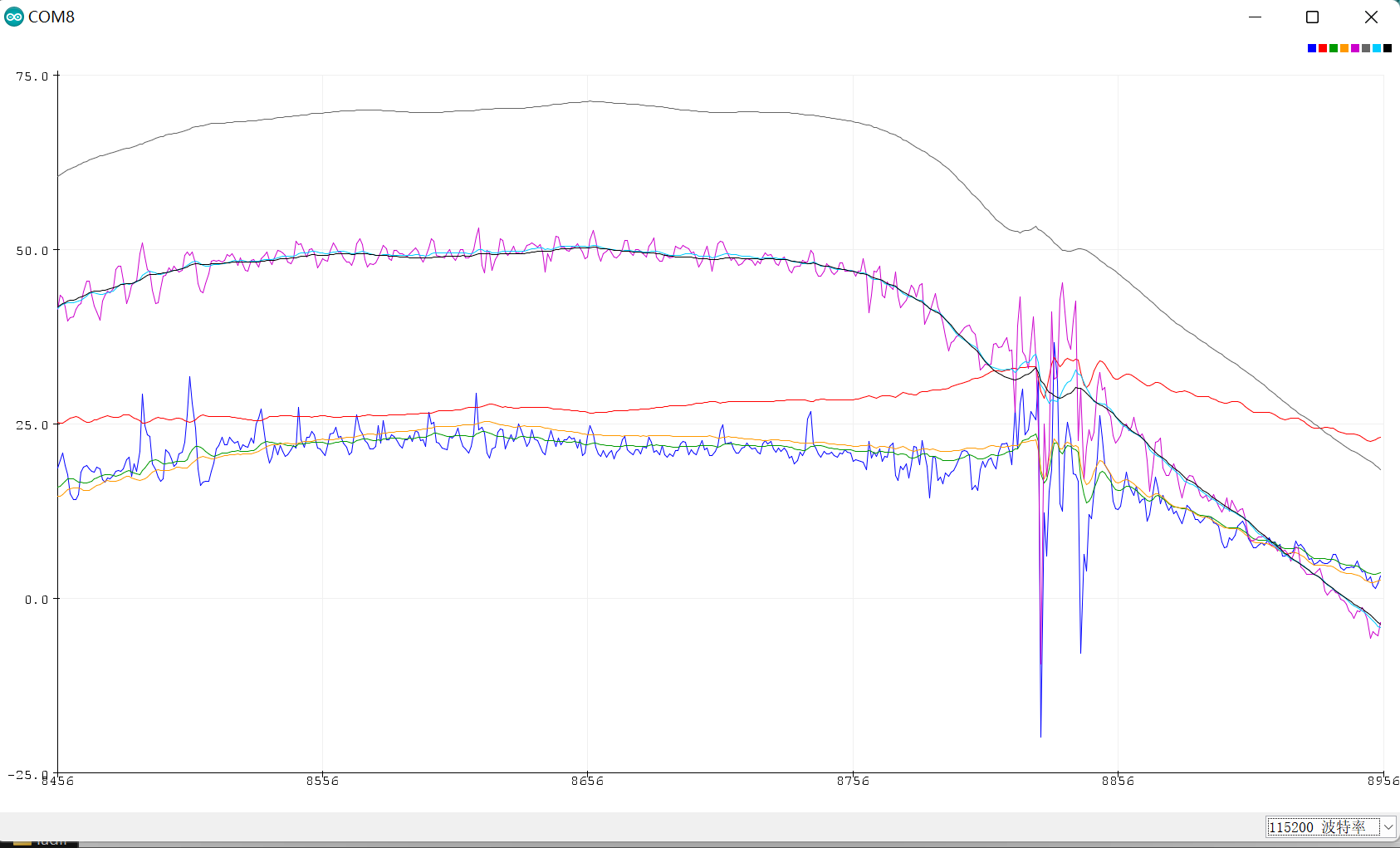

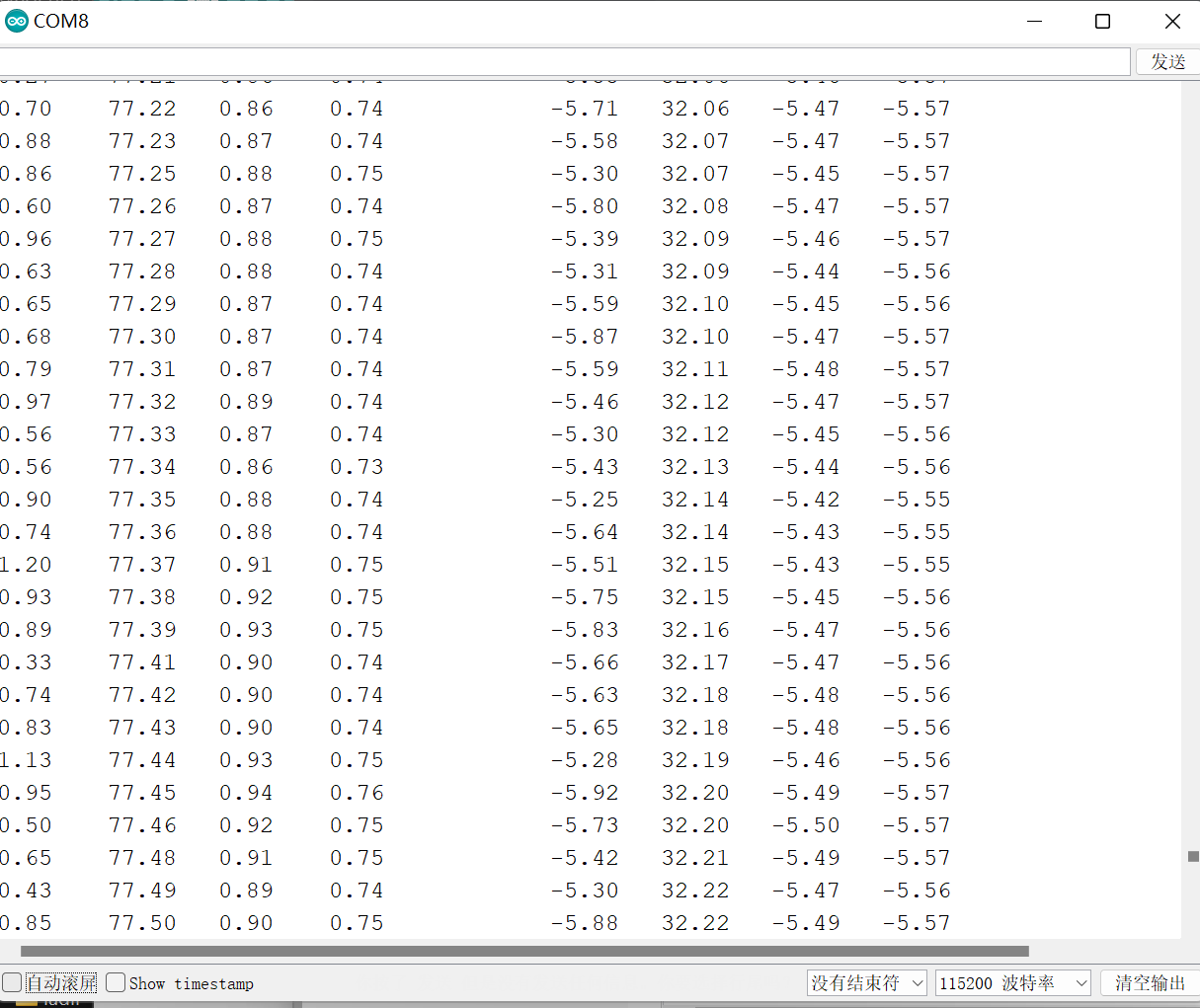

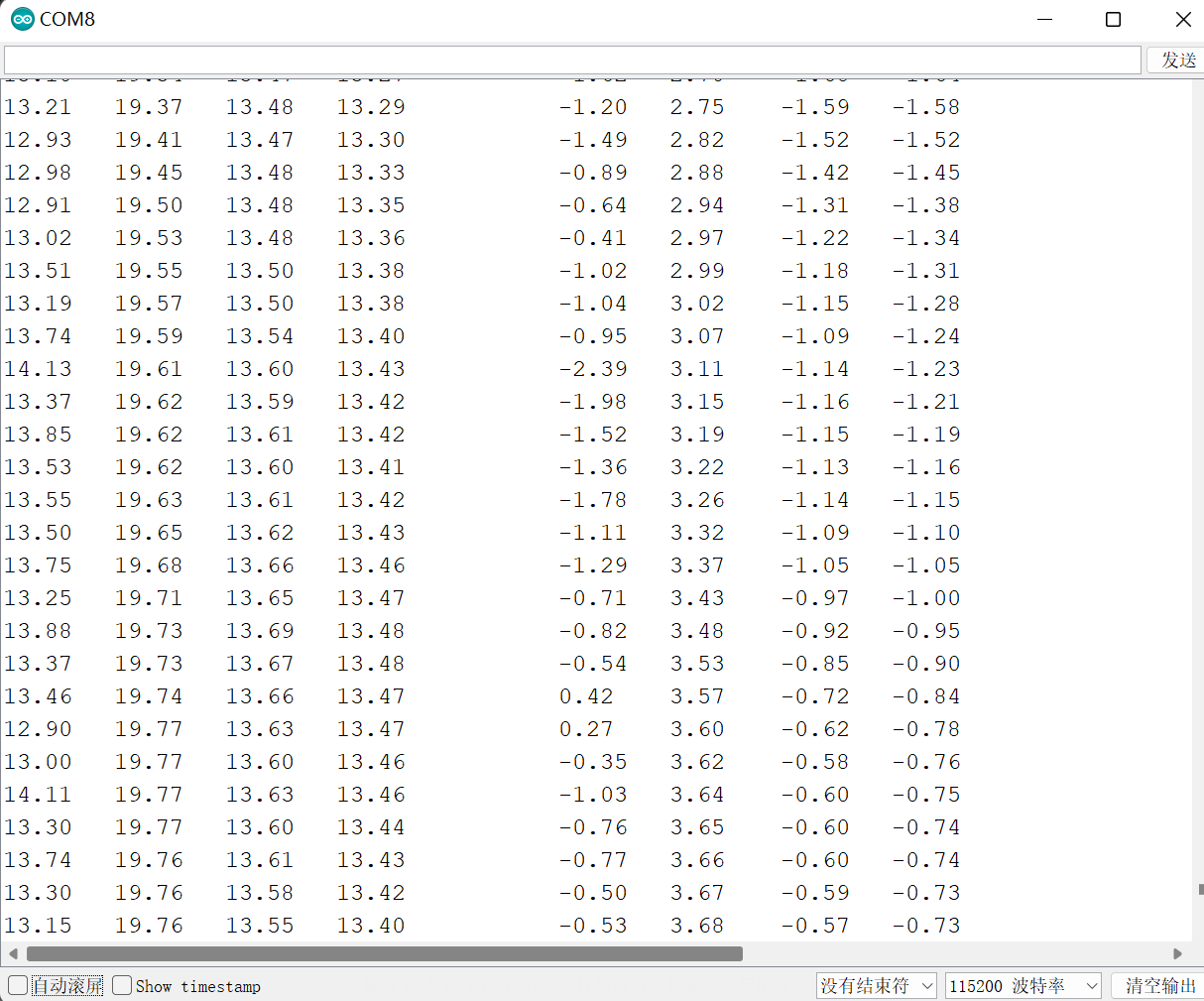

例子2 类基础3轴角度

z轴实测不稳定

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 | #include <Wire.h> uint32_t timer;uint8_t i2cData[14]; // Buffer for I2C dataunsigned long now, lastTime = 0;float dt; //微分时间 int16_t ax, ay, az, gx, gy, gz; //加速度计陀螺仪原始数据float aax=0, aay=0,aaz=0, agx=0, agy=0, agz=0; //角度变量long axo = 0, ayo = 0, azo = 0; //加速度计偏移量long gxo = 0, gyo = 0, gzo = 0; //陀螺仪偏移量 float pi = 3.1415926;float AcceRatio = 16384.0; //加速度计比例系数float GyroRatio = 131.0; //陀螺仪比例系数 uint8_t n_sample = 8; //加速度计滤波算法采样个数float aaxs[8] = {0}, aays[8] = {0}, aazs[8] = {0}; //x,y轴采样队列long aax_sum, aay_sum,aaz_sum; //x,y轴采样和 float a_x[10]={0}, a_y[10]={0},a_z[10]={0} ,g_x[10]={0} ,g_y[10]={0},g_z[10]={0}; //加速度计协方差计算队列float Px=1, Rx, Kx, Sx, Vx, Qx; //x轴卡尔曼变量float Py=1, Ry, Ky, Sy, Vy, Qy; //y轴卡尔曼变量float Pz=1, Rz, Kz, Sz, Vz, Qz; //z轴卡尔曼变量void setup(){ Serial.begin(115200); Wire.begin(); #if ARDUINO >= 157 Wire.setClock(400000UL); // Set I2C frequency to 400kHz #else TWBR = ((F_CPU / 400000UL) - 16) / 2; // Set I2C frequency to 400kHz #endif i2cData[0] = 7; // Set the sample rate to 1000Hz - 8kHz/(7+1) = 1000Hz i2cData[1] = 0x00; // Disable FSYNC and set 260 Hz Acc filtering, 256 Hz Gyro filtering, 8 KHz sampling i2cData[2] = 0x00; // Set Gyro Full Scale Range to ±250deg/s i2cData[3] = 0x00; // Set Accelerometer Full Scale Range to ±2g while (i2cWrite(0x19, i2cData, 4, false)); // Write to all four registers at once while (i2cWrite(0x6B, 0x01, true)); // PLL with X axis gyroscope reference and disable sleep mode while (i2cRead(0x75, i2cData, 1)); if (i2cData[0] != 0x68) { // Read "WHO_AM_I" register Serial.print(F("Error reading sensor")); while (1); } delay(100); // Wait for sensor to stabilize /* Set kalman and gyro starting angle */ unsigned short times = 200; //采样次数 for(int i=0;i<times;i++) { //accelgyro.getMotion6(&ax, &ay, &az, &gx, &gy, &gz); //读取六轴原始数值 while (i2cRead(0x3B, i2cData, 14)); ax = (int16_t)((i2cData[0] << 8) | i2cData[1]); ay = (int16_t)((i2cData[2] << 8) | i2cData[3]); az = (int16_t)((i2cData[4] << 8) | i2cData[5]); gx = (int16_t)((i2cData[8] << 8) | i2cData[9]); gy = (int16_t)((i2cData[10] << 8) | i2cData[11]); gz = (int16_t)((i2cData[12] << 8) | i2cData[13]);; axo += ax; ayo += ay; azo += az; //采样和 gxo += gx; gyo += gy; gzo += gz; } axo /= times; ayo /= times; azo /= times; //计算加速度计偏移 gxo /= times; gyo /= times; gzo /= times; //计算陀螺仪偏移} void loop(){ unsigned long now = millis(); //当前时间(ms) dt = (now - lastTime) / 1000.0; //微分时间(s) lastTime = now; //上一次采样时间(ms) while (i2cRead(0x3B, i2cData, 14)); ax = (int16_t)((i2cData[0] << 8) | i2cData[1]); ay = (int16_t)((i2cData[2] << 8) | i2cData[3]); az = (int16_t)((i2cData[4] << 8) | i2cData[5]); gx = (int16_t)((i2cData[8] << 8) | i2cData[9]); gy = (int16_t)((i2cData[10] << 8) | i2cData[11]); gz = (int16_t)((i2cData[12] << 8) | i2cData[13]);; float accx = ax / AcceRatio; //x轴加速度 float accy = ay / AcceRatio; //y轴加速度 float accz = az / AcceRatio; //z轴加速度 aax = atan(accy / accz) * (-180) / pi; //y轴对于z轴的夹角 aay = atan(accx / accz) * 180 / pi; //x轴对于z轴的夹角 aaz = atan(accz / accy) * 180 / pi; //z轴对于y轴的夹角 aax_sum = 0; // 对于加速度计原始数据的滑动加权滤波算法 aay_sum = 0; aaz_sum = 0; for(int i=1;i<n_sample;i++) { aaxs[i-1] = aaxs[i]; aax_sum += aaxs[i] * i; aays[i-1] = aays[i]; aay_sum += aays[i] * i; aazs[i-1] = aazs[i]; aaz_sum += aazs[i] * i; } aaxs[n_sample-1] = aax; aax_sum += aax * n_sample; aax = (aax_sum / (11*n_sample/2.0)) * 9 / 7.0; //角度调幅至0-90° aays[n_sample-1] = aay; //此处应用实验法取得合适的系数 aay_sum += aay * n_sample; //本例系数为9/7 aay = (aay_sum / (11*n_sample/2.0)) * 9 / 7.0; aazs[n_sample-1] = aaz; aaz_sum += aaz * n_sample; aaz = (aaz_sum / (11*n_sample/2.0)) * 9 / 7.0; float gyrox = - (gx-gxo) / GyroRatio * dt; //x轴角速度 float gyroy = - (gy-gyo) / GyroRatio * dt; //y轴角速度 float gyroz = - (gz-gzo) / GyroRatio * dt; //z轴角速度 agx += gyrox; //x轴角速度积分 agy += gyroy; //x轴角速度积分 agz += gyroz; /* kalman start */ Sx = 0; Rx = 0; Sy = 0; Ry = 0; Sz = 0; Rz = 0; for(int i=1;i<10;i++) { //测量值平均值运算 a_x[i-1] = a_x[i]; //即加速度平均值 Sx += a_x[i]; a_y[i-1] = a_y[i]; Sy += a_y[i]; a_z[i-1] = a_z[i]; Sz += a_z[i]; } a_x[9] = aax; Sx += aax; Sx /= 10; //x轴加速度平均值 a_y[9] = aay; Sy += aay; Sy /= 10; //y轴加速度平均值 a_z[9] = aaz; Sz += aaz; Sz /= 10; for(int i=0;i<10;i++) { Rx += sq(a_x[i] - Sx); Ry += sq(a_y[i] - Sy); Rz += sq(a_z[i] - Sz); } Rx = Rx / 9; //得到方差 Ry = Ry / 9; Rz = Rz / 9; Px = Px + 0.0025; // 0.0025在下面有说明... Kx = Px / (Px + Rx); //计算卡尔曼增益 agx = agx + Kx * (aax - agx); //陀螺仪角度与加速度计速度叠加 Px = (1 - Kx) * Px; //更新p值 Py = Py + 0.0025; Ky = Py / (Py + Ry); agy = agy + Ky * (aay - agy); Py = (1 - Ky) * Py; Pz = Pz + 0.0025; Kz = Pz / (Pz + Rz); agz = agz + Kz * (aaz - agz); Pz = (1 - Kz) * Pz; /* kalman end */ Serial.print(agx);Serial.print(","); Serial.print(agy);Serial.print(","); Serial.print(agz);Serial.println(); } |

【推荐】国内首个AI IDE,深度理解中文开发场景,立即下载体验Trae

【推荐】编程新体验,更懂你的AI,立即体验豆包MarsCode编程助手

【推荐】抖音旗下AI助手豆包,你的智能百科全书,全免费不限次数

【推荐】轻量又高性能的 SSH 工具 IShell:AI 加持,快人一步

· winform 绘制太阳,地球,月球 运作规律

· AI与.NET技术实操系列(五):向量存储与相似性搜索在 .NET 中的实现

· 超详细:普通电脑也行Windows部署deepseek R1训练数据并当服务器共享给他人

· 【硬核科普】Trae如何「偷看」你的代码?零基础破解AI编程运行原理

· 上周热点回顾(3.3-3.9)

2021-12-08 SolidWorks2020学习(1)安装中文破解版

2020-12-08 html设置滑动条