Arduino电机测速与PID原理及代码实现

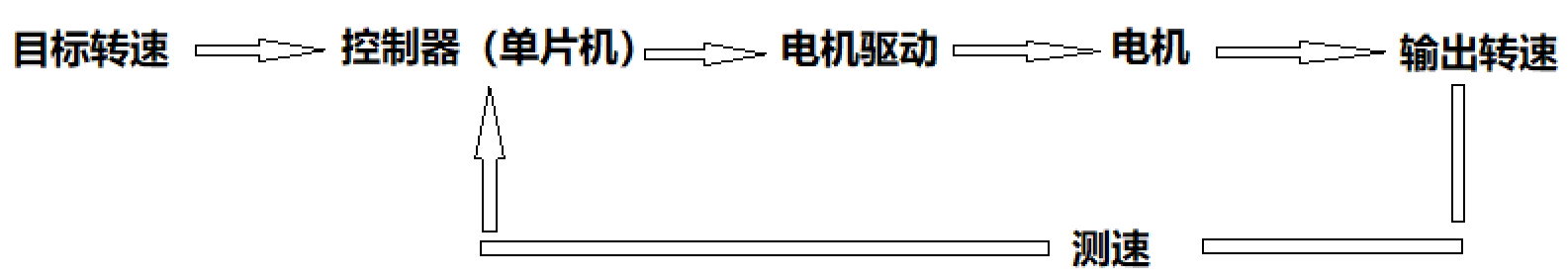

闭环控制

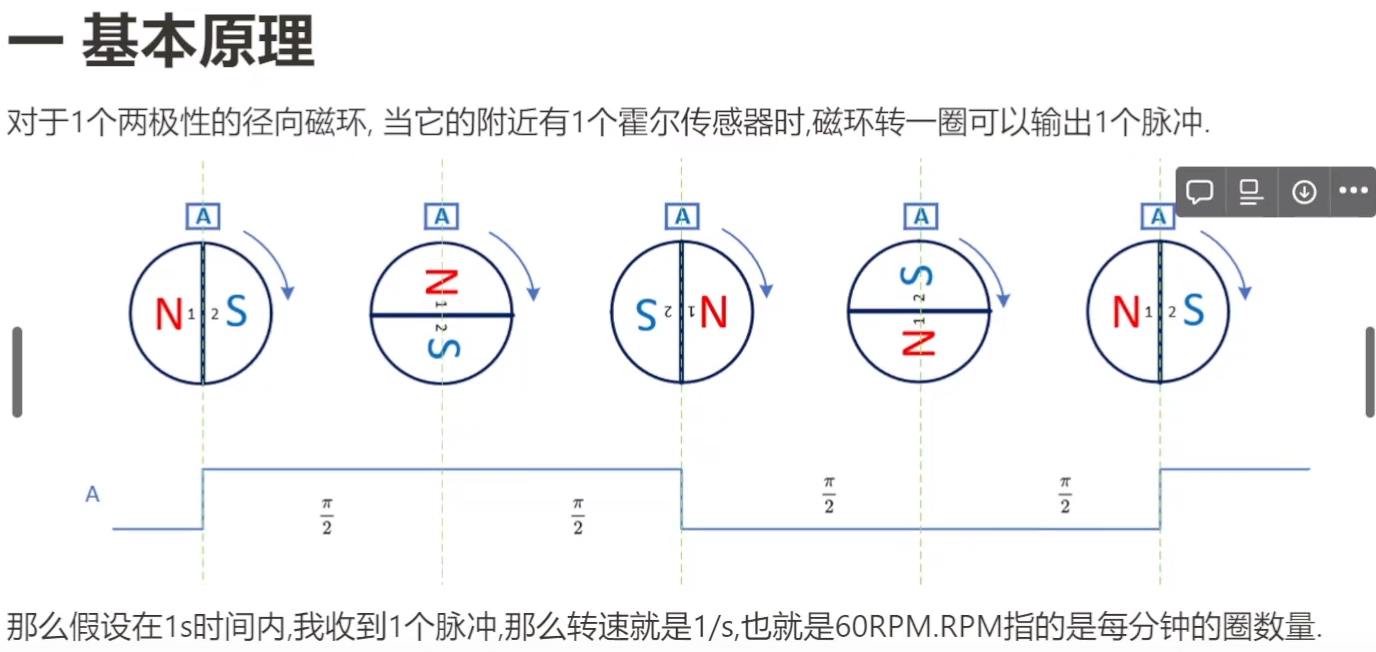

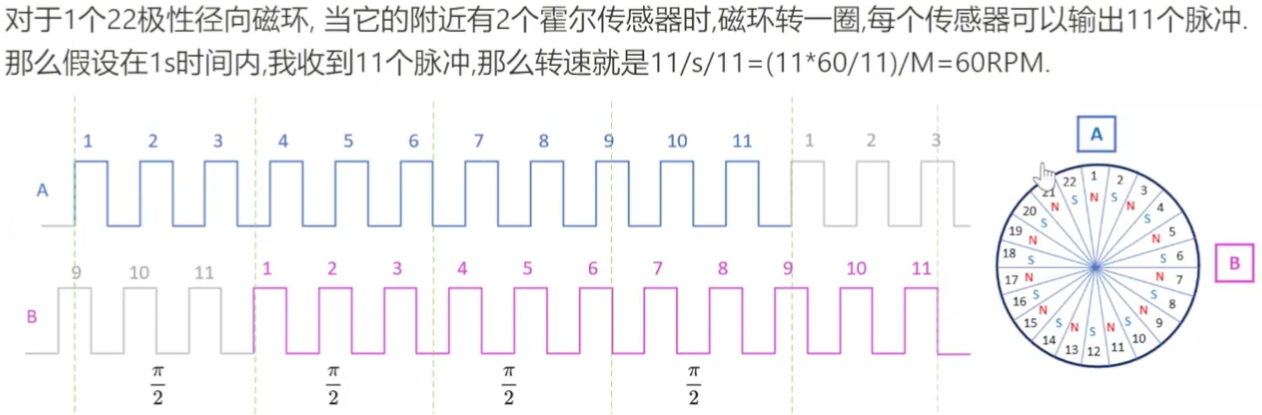

霍尔传感器编码器测速原理

来源:长话短说 霍尔传感器编码器测速原理分析_哔哩哔哩_bilibili

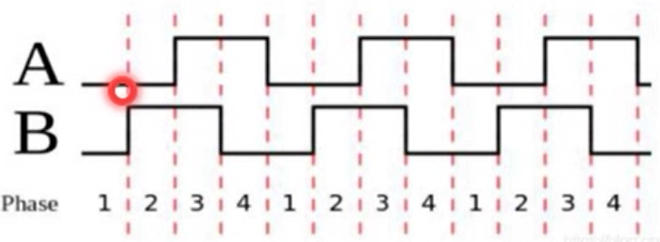

编码器不仅可检测脉冲,还可以检测边沿

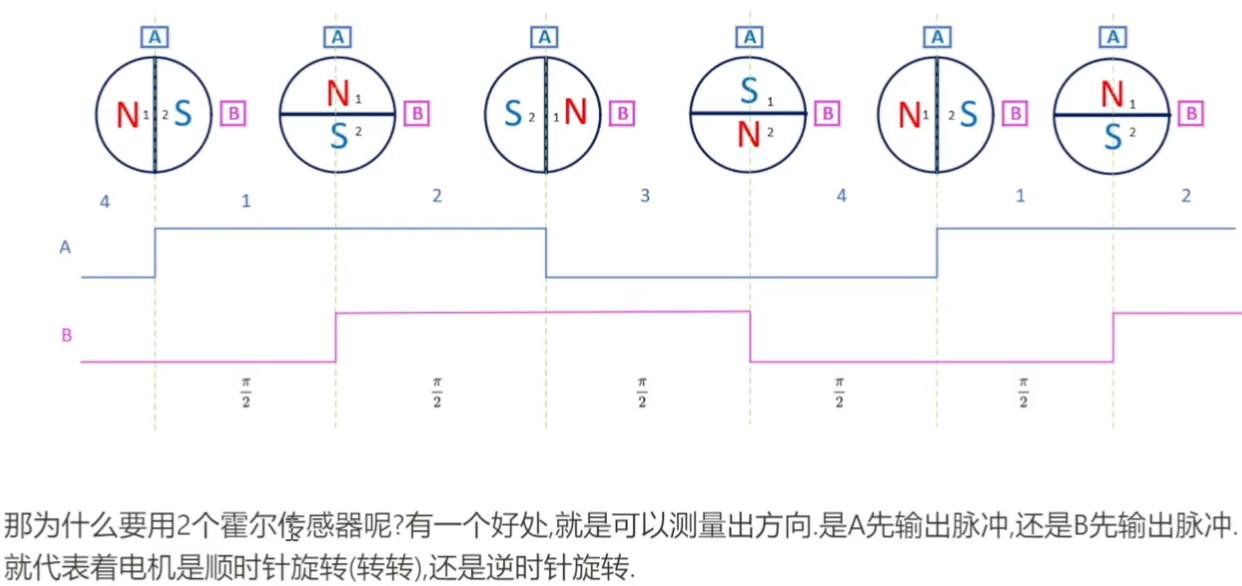

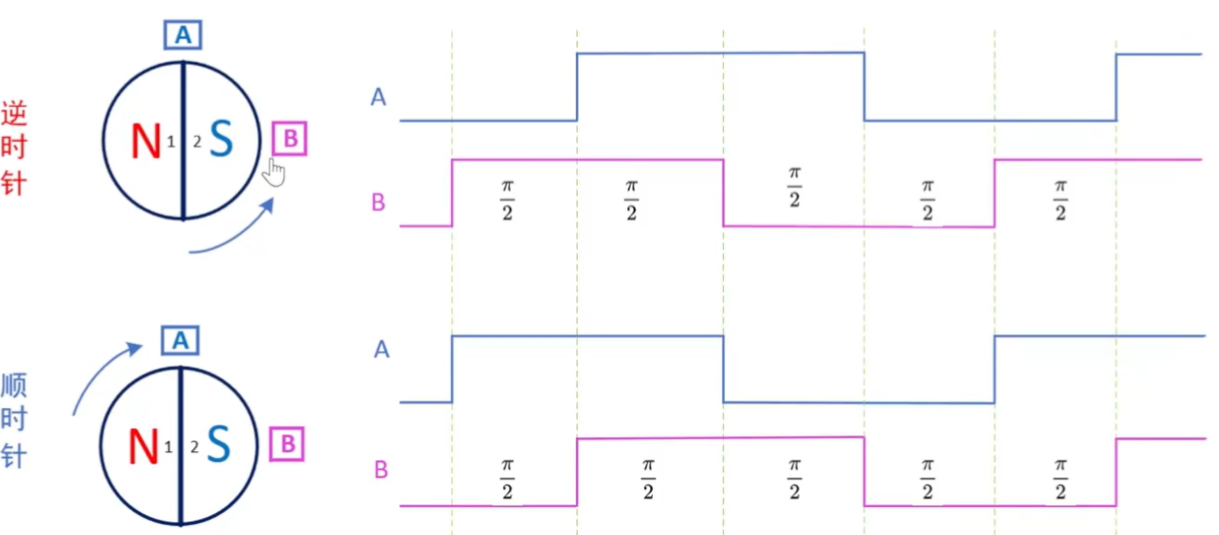

通过两个霍尔编码器可判断转向→输出有相位差的两组方波信号

eg. 在A的上升沿计数,B是高电平就正转、B是低电平就反转

电机测速代码1

来源:06_Arduino_PID教程_哔哩哔哩_bilibili

①定时器中断:在一定时间内计数

//定时器中断方法1:调库 #include<Timerone.h> // <MsTimer2.h> void setup() { Timer1.initialize(50000); // 每隔50000微秒调用一次中断函数 Timer1.attachInterrupt(timerIsr); // 中断函数为timerIsr } void timerIsr() { rpm = count / period * 60 / edges_per_cycle / reduction_ratio; //rpm: 转/分,电机前端真实转速 //count: 50ms内的信号(上升)边沿数 //period:调用中断函数的时间间隔,此处是0.05s //edges_per_cycle:电机后端每圈霍尔脉冲数,理论值为13 //reduction ratio: 电机减速比,理论值为20 count = 0; }

【能调用库还是推荐调用库,前提是知道该库的功能】

//定时器中断方法2:手写(不推荐) unsigned long curtime,oldtime; void loop() { curtime = millis(); // 返回当前时间,单位为ms int dt = abs(curtime - oldtime); if(dt > 50) { rpm = count / period * 60 / edges_per_cycle /reduction_ratio; count =0; oldtime = millis(); } }

②外部中断:计数的方法

如图:

假设希望计算A在某一段时间内的脉冲,需要知道何时产生脉冲(脉冲的上升沿在哪里)

因此检测边沿可用外部中断→出现一次下降沿就调用一次中断函数

//外部中断 int ENC A=2;//电机的编码器A端 int ENC_B=3;//电机的编码器B端 int count =0;//上升沿(脉冲)数量 void Code() { if(digitalRead(ENCB) == Low) //正转 { count +1; } if(digitalRead(ENC_B) == HIGH) //反转 { count -1; } void setup() { pinMode(ENC_A, INPUT); pinMode(ENC_B, INPUT); attachInterrupt(0, Code, FALLING); //UN0管脚2对应参数为0,3对应参数为1 //在ENCA下降沿处执行Code }

【更高级的方式:四倍频技术,计上下降沿,提高四倍精度→同时检测A、B的外部中断】

void setup() { pinMode(ENC_A,INPUT); pinMode(ENC_B,INPUT); attachInterrupt(0,Code0,CHANGE); attachInterrupt(1,Code1,CHANGE); } void Code0() { if(ENCA=LOW) // 判断A为下降沿 { if(digitalRead(ENC_B) == LOW) // 正转 { count += 1; } if(digitalRead(ENC_B) == HIGH) // 反转 { count -= 1; } } else // 未完成 } void Code1(){} //未完成

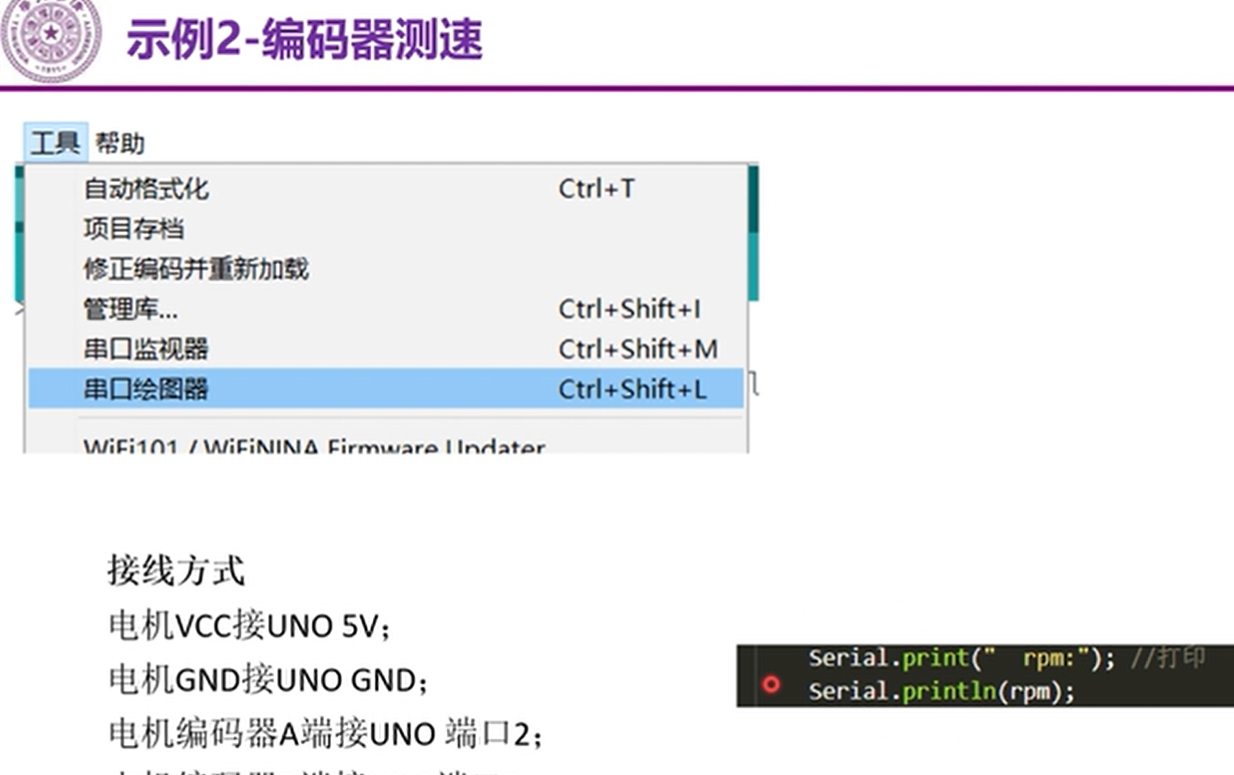

电机测速代码2

来源:用示波器理解 Arduino 小车的测速方法_哔哩哔哩_bilibili

//Include the TimerOne Library from Paul Stoffregen #include "TimerOne.h" //Constants for Interrupt Pins //Change values if not using Arduino Uno const byte MOTOR1 = 2; //Motor 1 Interrupt Pin - INT 0 const byte MOTOR2 = 3; //Motor 2 Interrupt Pin - INT 1 //Integers for pulse counters unsigned int counter1 = 0; unsigned int counter2 = 0; //Float for number of slots in encoder disk float diskslots 30; //Change to match value of encoder disk //Interrupt Service Routines //Motor 1 pulse count ISR void ISR_count1() { counter1++; // increment Motor 1 counter value } //Motor 2 pulse count ISR void ISR_count2() { counter2++; // increment Motor 2 counter value } //TimerOne ISR void ISR timerone ( { Timerl.detachInterrupt (); // Stop the timer Serial.print ("Motor Speed 1:"); float rotationl = (counterl / diskslots) * 60.00; //calculate RPM for Motor 1 Serial.print (rotationl); Serial.print (" RPM - "); counterl = 0; // reset counter to zero Serial.print ("Motor Speed 2:"); float rotation2 = (counter2 / diskslots) * 60.00; //calculate RPM for Motor 2 Serial.print (rotation2); Serial.println (" RPM"); counter2 = 0; // reset counter to zero Timerl.attachInterrupt ( ISR_timerone ); // Enable the timer } void setup() { Serial.begin(9600); Timerl.initialize(1000000); // set timer for lsec attachInterrupt (digitalPinToInterrupt (MOTOR1), ISR_count1, RISING); // Increase counter 1 when speed sensor pin goes High attachInterrupt (digitalPinToInterrupt (MOTOR2), ISR_count2, RISING); // Increase counter 2 when speed sensor pin goes High Timer1.attachInterrupt( ISR_timerone ); // Enable the timer } void loop() { //Nothing in the loop! //You can place code here }

PID算法

根据反馈进行控制

1.误差比例控制 : $K_p$增大,加快系统响应

$err(t) = goal - rpm(t);$

$pwm(t) = K_p × err(t);$

2.微分阻尼项 : $K_d = K_p × T_d$

$pwm(t) = K_p × (err(t) + T_d × \frac{d(err(t))}{dt}$

3.积分消除静态误差:$K_i = K_p / T_i$

$pwm(t) = K_p × (err(t) + \frac{1}{T_i}\int ^t_0err(\tau)d\tau + T_d × \frac{d(err(t))}{dt})$

位移式PID

【连续时间】$pwm(t) = K_p × err(t) + K_i\int ^t_0err(\tau)d\tau + K_d × \frac{d(err(t))}{dt}$

【离散时间】$pwm(k) = K_p × err(k) + {K_i} × \sum ^k_0err(i) + K_d × (err(k) - err(k-1)$

适用:执行机构不带积分部件的对象

缺点:误差积累大

增量式PID

【连续时间】$dpwm(t) = K_p × \frac{d(err(t))}{dt}+ K_i × err(t) + K_d × \frac{d^2(err(t))}{dt^2}$

【离散时间】$dpwm(k) = K_p × (err(k)-err(k-1)) + K_i × err(k) + K_d × [(err(k) - err(k-1))- (err(k-1)-err(k-2)]$

适用:执行机构带积分部件的对象 eg.步进电机

缺点:积分截断大、有静态误差

接线

电池正极连接L298N12V供电

电池负极连接L298N供电GND

电机M+连接L298NOUT1

电机M-连接L298NOUT2

L298NIN1连接UNO10

L298NIN2连接UNO11

L298NENA连接UNO6

L298N5V连接UNO5V

L298N供电GND连接UNO GND

电机VCC接UNO 5V

电机GND接JNO GND

电机编码器A端接UNO端口2

电机编码器B端接UNO端口3

float err = 0,derr = 0,dderr = 0; float Kp,Ki,Kd; unsigned Long curtime,oldtime; void loop() { curtime=millis();/返回当前时间,单位为ms int dt abs(curtime = oldtime); if(dt > 50) { oldtime = millis(); rpm = count / period * 60 / edges_per_cycle / reduction ratio; count = 0; Serial.print(" rpm:");/打印 Serial.println(rpm); pwm += PID(50, rpm); if(abs(pwm)>255)/判断PWM是否超过最大值 if(pwm<0)//控制电机正反转… else analogwrite(PWM,pwm); } } int PID(fLoat goal,fLoat now) { dderr = goal-now - err-derr; derr = goal - now-err; err = goal - now; float dPWM = Ki * (err) + Kp * (derr) + Kd * (dderr); return dPWM; }

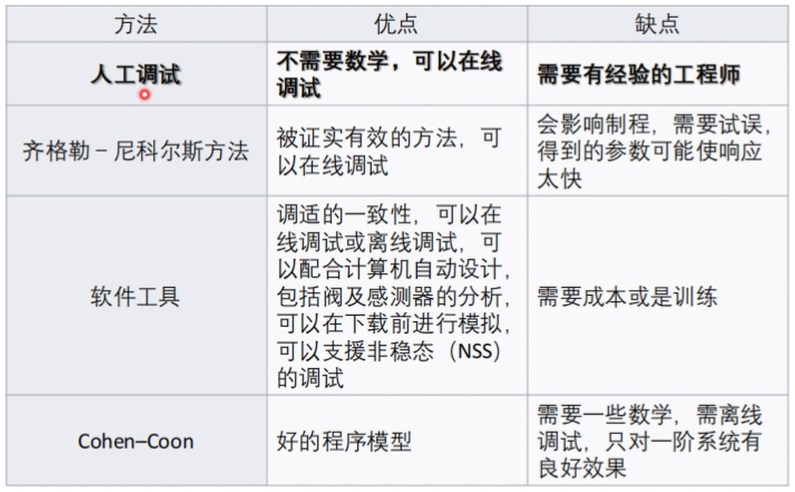

PID调参

先是比例后积分,最后再把微分加,

曲线振荡很频繁,比例度盘要放大,

曲线漂浮绕大弯,比例度盘往小扳,

曲线偏离回复慢,积分时间往下降,

曲线波动周期长,积分时间再加长,

【06_Arduino_PID教程】 【精准空降到 38:09】

作业

浙公网安备 33010602011771号

浙公网安备 33010602011771号