【关节电机专栏】ESP32 TWAI CAN Arduino库驱动大然电机(PDA-04)

前言

大然电机官方提供了 STM32、Arduino 等函数库,但是没有提供ESP32的函数库

ESP32、ESP32-S3都自带有CAN接口,使用起来很方便,同时利于集成蓝牙功能,因此想办法弄出来了SP32-S3/ESP32的驱动库。

环境:PlatformIO、Arduino框架、ESP32-S3(ESP32也适用)

完整代码-项目仓库:https://gitee.com/wenlilili/dr-joint-motor-esp32-lib

本项目用到了ESP32-TWAI-CAN底层CAN库,需要提前调用好 Platform 的库。不会的话参考文章:【关节电机专栏】ESP32 TWAI CAN Arduino库驱动小米电机(CyberGear微电机)

驱动库介绍:

共包含以下三对文件(.cpp/.h)

分别为数据转换(如 float 与 int 之间的转换)、帧结构(标准帧还是扩展帧?遥控帧还是数据帧?帧ID的具体含义?)以及上层的协议命令。

1. 首先,在main.c中包含以下头文件

#include "twai_can_dr_motor_frame.h"

#include "twai_can_dr_motor_protocol.h"

2. 然后,在setup() 函数中初始化电机CAN总线 (设置比特率、队列等等) Motor_CAN_Init();

3. 最后,在loop()函数中,或在中断中,调用电机控制类函数(比如控制角度、速度、自适应等等)

比如: set_angle(id_num, angle, speed, param, mode); // 控制 7 号关节转到 0°

具体思路之1—— 如何进行CAN初始化?

以下是ESP32-TWAI-CAN库的CAN总线初始化函数(begin())

bool begin(TwaiSpeed twaiSpeed = TWAI_SPEED_500KBPS,

int8_t txPin = -1, int8_t rxPin = -1,

uint16_t txQueue = 0xFFFF, uint16_t rxQueue = 0xFFFF,

twai_filter_config_t* fConfig = nullptr,

twai_general_config_t* gConfig = nullptr,

twai_timing_config_t* tConfig = nullptr);主要需要知道以下数据:

- CAN的引脚

- 电机驱动板对应的比特率

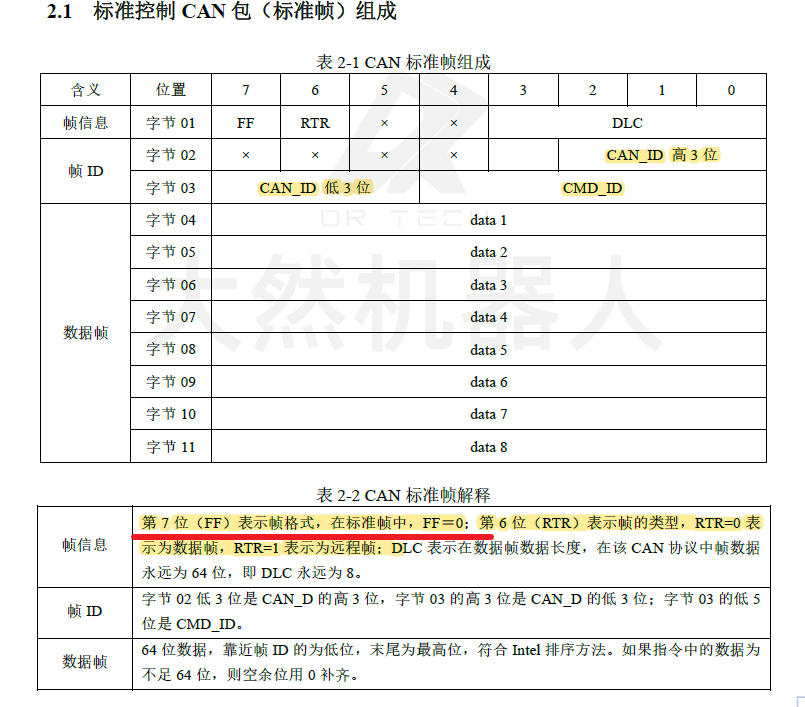

如何实现发送 CAN 消息?——第一步:明确帧格式

有的电机(大然电机)是标准帧,有的电机(小米电机)是扩展帧,下面分别给出举例:

小米电机

/*

小米电机驱动器通信协议及使用说明

电机通信为 CAN 2.0 通信接口,波特率 1Mbps,采用扩展帧格式,如下所示:

数据域 29 位 ID 8Byte 数据区

大小 Bit28~bit24 bit23~8 bit7~0 Byte0~Byte7

描述 通信类型 数据区 2 目标地址 数据区 1

*/由上面的定义,可以定义一个帧的结构体:

//发送数据包

typedef struct {

uint32_t id:8; //8位CAN ID

uint32_t data:16; //16位数据

uint32_t mode:5; //5位模式

uint32_t res:3; //3位保留

uint8_t tx_data[8];

}can_frame_t;其发送帧的函数如下:

//底层的CAN发送指令,小米电机采用扩展帧,数据帧的格式

static void CAN_Send_Frame(can_frame_t* frame)

{

CanFrame obdFrame = { 0 };

uint32_t id_val,data_val,mode_val;

uint32_t combined_val;

obdFrame.extd = 1; //0-标准帧; 1-扩展帧 小米电机采用扩展帧

obdFrame.rtr = 0; //0-数据帧; 1-远程帧

obdFrame.ss = 0; //0-错误重发; 1-单次发送(仲裁或丢失时消息不会被重发),对接收消息无效

obdFrame.self = 0; //0-不接收自己发送的消息,1-接收自己发送的消息,对接收消息无效

obdFrame.dlc_non_comp = 0; //0-数据长度不大于8(ISO 11898-1); 1-数据长度大于8(非标); 数据长度为标准长度

//拼接ID

id_val = frame->id;

data_val = frame->data;

mode_val = frame->mode;

combined_val |= (mode_val << 24);

combined_val |= (data_val << 8);

combined_val |= id_val;

obdFrame.identifier = combined_val; //普通帧直接写id,扩展帧需要计算。11/29位ID

obdFrame.data_length_code = 8; //要发送的字节数

for (int i = 0; i < 8; i++)

{

obdFrame.data[i] = frame->tx_data[i];

}

ESP32Can.writeFrame(obdFrame);

}大然电机

与之相对,大然电机采用标准帧(帧信息为1字节,帧ID为两个字节):

因此可以参照小米电机的代码,写出大然电机CAN发送frame的代码

// CAN发送函数

void send_command(uint8_t id_num, char cmd, unsigned char *data,uint8_t rt)

{

//short id_list = (id_num << 5) + cmd;

/* Can_Send_Msg(id_list, 8, data);

uint8_t Can_Send_Msg(uint32_t id,uint8_t len,uint8_t *data) {

uint32_t i=0;

static uint32_t TxMailbox;

CAN_TxHeaderTypeDef CAN_TxHeader;

HAL_StatusTypeDef HAL_RetVal;

CAN_TxHeader.IDE = CAN_ID_STD;

CAN_TxHeader.StdId = id;

CAN_TxHeader.DLC = len;

CAN_TxHeader.RTR = CAN_RTR_DATA;

CAN_TxHeader.TransmitGlobalTime = DISABLE;

while(HAL_CAN_GetTxMailboxesFreeLevel(&SERVO_CAN) == 0)

{

i++;

if(i>0xffffe)

return 1;

}

HAL_RetVal = HAL_CAN_AddTxMessage(&SERVO_CAN,&CAN_TxHeader,data,&TxMailbox);

if(HAL_RetVal != HAL_OK)

return 1;

return 0;

}*/

CanFrame obdFrame = { 0 };

uint16_t combined_val;

obdFrame.extd = 0; //0-标准帧; 1-扩展帧 小米电机采用扩展帧;大然电机采用标准帧

obdFrame.rtr = 0; //0-数据帧; 1-远程帧

obdFrame.ss = 0; //0-错误重发; 1-单次发送(仲裁或丢失时消息不会被重发),对接收消息无效

obdFrame.self = 0; //0-不接收自己发送的消息,1-接收自己发送的消息,对接收消息无效

obdFrame.dlc_non_comp = 0; //0-数据长度不大于8(ISO 11898-1); 1-数据长度大于8(非标); 数据长度为标准长度

combined_val |= (id_num << 5);

combined_val |= cmd;

obdFrame.identifier = combined_val; //普通帧直接写id,扩展帧需要计算。11/29位ID (这里很重要)(这里感觉有问题??????)

obdFrame.data_length_code = 8; //要发送的字节数

for (int i = 0; i < 8; i++)

{

obdFrame.data[i] = data[i];

}

ESP32Can.writeFrame(obdFrame);

}

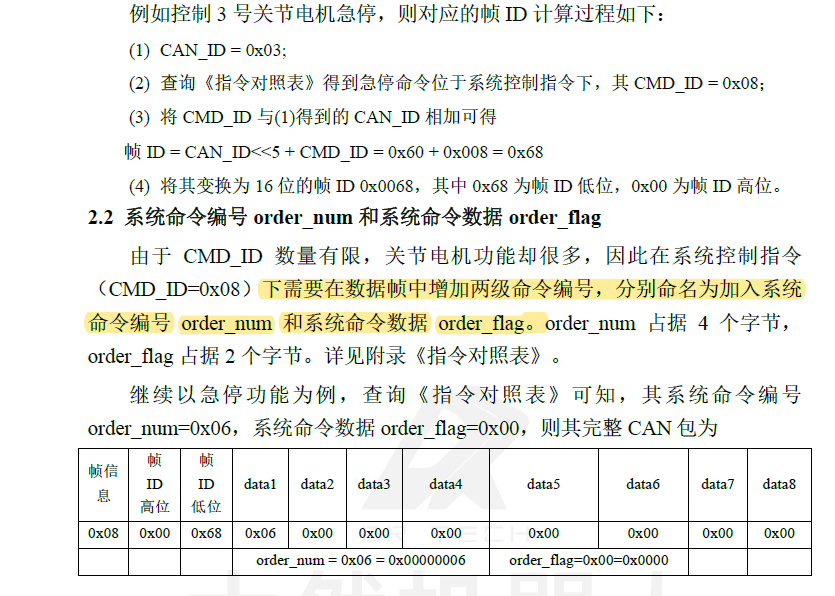

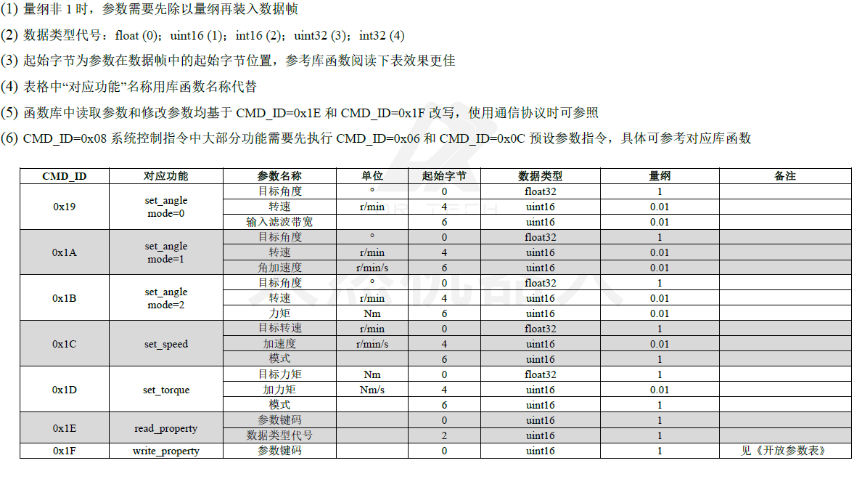

具体思路之2——如何发送有实际效用的数据帧——找电机驱动板的《指令对照表》

以下是大然电机协议说明书:(完整的命令由 帧ID中的CMD_ID + 数据帧中的 order_num (4个字节) + order_flag(2个字节)共同定义)

大然电机《指令对照表》

大然电机的函数库中已经有这部分内容,由于完成了底层的CAN信息发送,这部分直接复制即可,如

/**

* @brief 单个关节速度控制函数。

* 控制指定关节编号的关节按照指定的速度连续整周转动。

*

* @param id_num 需要设置的关节ID编号,如果不知道当前关节ID,可以用0广播,如果总线上有多个关节,则多个关节都会执行该操作。

* @param speed 目标速度(r/min)

* @param param mode=1, 前馈扭矩(Nm); mode!=1,或目标加速度((r/min)/s)

* @param mode 控制模式选择

* mode=1, 速度前馈控制模式,关节将目标速度直接设为speed

* mode!=1,速度爬升控制模式,关节将按照目标加速度axis0.controller.config_.vel_ramp_rate变化到speed。

* @note 在速度爬升模式下,如果目标加速度设置为0,则关节速度将保持当前值不变。

*/

void set_speed(uint8_t id_num, float speed, float param, int mode)

{

float factor = 0.01;

float f_speed = speed;

if (mode == 0)

{

int s16_torque = (int)((param) / factor);

if( f_speed == 0)

s16_torque = 0;

unsigned short u16_input_mode = 1;

float value_data[3]= {f_speed,s16_torque,u16_input_mode};

int type_data[3]= {0,2,1};

format_data(value_data,type_data,3,"encode");

}

else

{

int s16_ramp_rate = (int)((param) / factor);

unsigned short u16_input_mode = 2;

float value_data[3]= {f_speed,s16_ramp_rate,u16_input_mode};

int type_data[3]= {0,2,1};

format_data(value_data,type_data,3,"encode");

}

send_command(id_num,0x1c,data_list.byte_data,0);

}

附:ESP32-TWAI-CAN库Readme文档

ESP32-TWAI-CAN

Usage

```cpp

#include <ESP32-TWAI-CAN.hpp>

// Default for ESP32

#define CAN_TX 5

#define CAN_RX 4

CanFrame rxFrame;

void sendObdFrame(uint8_t obdId) {

CanFrame obdFrame = { 0 };

obdFrame.identifier = 0x7DF; // Default OBD2 address;

obdFrame.extd = 0;

obdFrame.data_length_code = 8;

obdFrame.data[0] = 2;

obdFrame.data[1] = 1;

obdFrame.data[2] = obdId;

obdFrame.data[3] = 0xAA; // Best to use 0xAA (0b10101010) instead of 0

obdFrame.data[4] = 0xAA; // CAN works better this way as it needs

obdFrame.data[5] = 0xAA; // to avoid bit-stuffing

obdFrame.data[6] = 0xAA;

obdFrame.data[7] = 0xAA;

// Accepts both pointers and references

ESP32Can.writeFrame(obdFrame); // timeout defaults to 1 ms

}

void setup() {

// Setup serial for debbuging.

Serial.begin(115200);

// Set pins

ESP32Can.setPins(CAN_TX, CAN_RX);

// You can set custom size for the queues - those are default

ESP32Can.setRxQueueSize(5);

ESP32Can.setTxQueueSize(5);

// .setSpeed() and .begin() functions require to use TwaiSpeed enum,

// but you can easily convert it from numerical value using .convertSpeed()

ESP32Can.setSpeed(ESP32Can.convertSpeed(500));

// You can also just use .begin()..

if(ESP32Can.begin()) {

Serial.println("CAN bus started!");

} else {

Serial.println("CAN bus failed!");

}

// or override everything in one command;

// It is also safe to use .begin() without .end() as it calls it internally

if(ESP32Can.begin(ESP32Can.convertSpeed(500), CAN_TX, CAN_RX, 10, 10)) {

Serial.println("CAN bus started!");

} else {

Serial.println("CAN bus failed!");

}

}

void loop() {

static uint32_t lastStamp = 0;

uint32_t currentStamp = millis();

if(currentStamp - lastStamp > 1000) { // sends OBD2 request every second

lastStamp = currentStamp;

sendObdFrame(5); // For coolant temperature

}

// You can set custom timeout, default is 1000

if(ESP32Can.readFrame(rxFrame, 1000)) {

// Comment out if too many requests

Serial.printf("Received frame: %03X \r\n", rxFrame.identifier);

if(rxFrame.identifier == 0x7E8) { // Standard OBD2 frame responce ID

Serial.printf("Collant temp: %3d°C \r\n", rxFrame.data[3] - 40); // Convert to °C

}

}

}

```Advanced

```cpp

// Everything is defaulted so you can just call .begin() or .begin(TwaiSpeed)

// Calling begin() to change speed works, it will disable current driver first

bool begin(TwaiSpeed twaiSpeed = TWAI_SPEED_500KBPS,

int8_t txPin = -1, int8_t rxPin = -1,

uint16_t txQueue = 0xFFFF, uint16_t rxQueue = 0xFFFF,

twai_filter_config_t* fConfig = nullptr,

twai_general_config_t* gConfig = nullptr,

twai_timing_config_t* tConfig = nullptr);

```

```c

typedef struct {

union {

struct {

//The order of these bits must match deprecated message flags for compatibility reasons

uint32_t extd: 1; /**< Extended Frame Format (29bit ID) */

uint32_t rtr: 1; /**< Message is a Remote Frame */

uint32_t ss: 1; /**< Transmit as a Single Shot Transmission. Unused for received. */

uint32_t self: 1; /**< Transmit as a Self Reception Request. Unused for received. */

uint32_t dlc_non_comp: 1; /**< Message's Data length code is larger than 8. This will break compliance with ISO 11898-1 */

uint32_t reserved: 27; /**< Reserved bits */

};

//Todo: Deprecate flags

uint32_t flags; /**< Deprecated: Alternate way to set bits using message flags */

};

uint32_t identifier; /**< 11 or 29 bit identifier */

uint8_t data_length_code; /**< Data length code */

uint8_t data[TWAI_FRAME_MAX_DLC]; /**< Data bytes (not relevant in RTR frame) */

} twai_message_t;

/**

* @brief Structure for bit timing configuration of the TWAI driver

*

* @note Macro initializers are available for this structure

*/

typedef struct {

uint32_t brp; /**< Baudrate prescaler (i.e., APB clock divider). Any even number from 2 to 128 for ESP32, 2 to 32768 for ESP32S2.

For ESP32 Rev 2 or later, multiples of 4 from 132 to 256 are also supported */

uint8_t tseg_1; /**< Timing segment 1 (Number of time quanta, between 1 to 16) */

uint8_t tseg_2; /**< Timing segment 2 (Number of time quanta, 1 to 8) */

uint8_t sjw; /**< Synchronization Jump Width (Max time quanta jump for synchronize from 1 to 4) */

bool triple_sampling; /**< Enables triple sampling when the TWAI controller samples a bit */

} twai_timing_config_t;

/**

* @brief Structure for acceptance filter configuration of the TWAI driver (see documentation)

*

* @note Macro initializers are available for this structure

*/

typedef struct {

uint32_t acceptance_code; /**< 32-bit acceptance code */

uint32_t acceptance_mask; /**< 32-bit acceptance mask */

bool single_filter; /**< Use Single Filter Mode (see documentation) */

} twai_filter_config_t;

```

【推荐】国内首个AI IDE,深度理解中文开发场景,立即下载体验Trae

【推荐】编程新体验,更懂你的AI,立即体验豆包MarsCode编程助手

【推荐】抖音旗下AI助手豆包,你的智能百科全书,全免费不限次数

【推荐】轻量又高性能的 SSH 工具 IShell:AI 加持,快人一步

· 阿里最新开源QwQ-32B,效果媲美deepseek-r1满血版,部署成本又又又降低了!

· 开源Multi-agent AI智能体框架aevatar.ai,欢迎大家贡献代码

· Manus重磅发布:全球首款通用AI代理技术深度解析与实战指南

· 被坑几百块钱后,我竟然真的恢复了删除的微信聊天记录!

· AI技术革命,工作效率10个最佳AI工具

2024-01-09 【机试刷题】顺时针旋转矩阵